Abstract

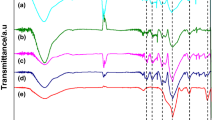

High-temperature oxidation and electroless nickel plating are two common surface modification processes to improve the wettability of SiC/Al interface. The structure and properties of SiC/SiO2/Al and SiC/Ni/Al interface layers were studied for the preparation of aluminum alloy drill pipe. Two kinds of 6.5%SiC/Al–Cu–Mg–Zn composite ingot were prepared using vacuum melting/casting method, and the added SiC particles in the composites were modified by high-temperature oxidation and electroless nickel plating, respectively. Analysis of structure demonstrates that the interface structures of composites ingot are SiC/SiO2/Al structure and SiC/Ni/Al structure, respectively. For SiC/SiO2/Al interface structure, a smooth and dense SiO2 film is well bonded to SiC and Al by chemical bonding. For SiC/Ni/Al interface structure, there is a very thin Ni film between SiC and Al and the bonding strength between Ni and Al is not so strong. Results of the performance test of the composites indicate that the tensile strength and compressive strength of the composites with SiC/SiO2/Al interface structure, respectively, increase by 7.51% and 24.90%, compared with the composites ingot with SiC/Ni/Al interface structure.

Similar content being viewed by others

References

Wang X H, Peng Z W, Zhong S Y, Wang G R, Hu Q G, and Lin Y H, Int J Electrochem Sci13 (2018) 8970.

Wang X H, Guo J, Lin Y H, Guo X H, Peng J, and Zhou X Y, Surf Interface Anal, 48 (2016) 860.

Wang X H, Peng Z W, Ma L, Lin Y H, Li G X, and Wang H L, Int J Electrochem Sci, 12 (2017) 11006.

Liu Y, Hua X Z, Huang J H, Cui X, Zhou X L, and Yu Y W. Chin J Corros Prot36 (2016) 130.

Zhao W X, Effect of SiC Pretreatment on Microstructure and Tensile Properties of SiCp/2014Al Composites, Jilin University (2015).

Guo Y C, Cao C, Li J P, Xu T, and Dong S P, Therm Process45 (2016) 131.

Li L B, An M Z, and Wu G H, J Inorg Chem21 (2005) 982.

Marumo C, and Pask J A, J Mater Sci12 (1997) 223.

Tekmen C, Saday F, and Cocen U, J Compos Mater42 (2008) 1671.

Tong H, Hu Z F, Zhang Z, Cai Z W, Qi C Y, He D H, Mo F, and Jiang K Y, Met Funct Mater22 (2015) 53.

Liu J S, Wettability and Interfacial Structure of Al Alloys with SiC and SiO 2, Jilin University (2016).

Zhao D W, and Mi G F, Aerosp Manuf Technol (2008) 26.

Xia C R, Guo X X, and Li F Q, Colloids Surf A Physicochem Eng Asp179 (2001) 229.

Tekmen C, Saday F, and Cocen U, J compos Mater42 (2008) 1671.

Pázmán J, Mádai V, and Tóth J, Int J Microstruct Mater Prop7 (2012) 220.

Liu J A, and Shao L F, Typical Atlas of Aluminum Alloy Extrusion Die, Chemical Industry Press, Beijing (2007).

Wang C T, Ma L Q, Yin M Y, Liu Z Y, Ding Y, Zhang H, and Chen Y G, Spec Cast Nonferrous Alloys309 (2010).

Ye Y, Study on Enhanced Phase Dispersion and Interface Behavior of SiCp/Al–Cu–Mg Composites, Southwest Petroleum University (2017).

Wang W M, Pan F S, Sun X W, Zeng S M, and Lu Y, J Chongqing Univ (Nat Sci Ed) (2004) 108.

Liu J Y, Liu Y C, Liu G Q, Yin Y S, and Shi Z L, Chin J Nonferrous Met12 (2002).

Mitlin D, Morris J W, and Radmilovic V, Metall Mater Trans A31 (2000) 2697.

Barlow I C, Rainforth W M, and Jones H, J Mater Sci35 (2000) 1413.

Wei H, Guan H R, Sun X F, Zheng Q, Hou G C, and Hu Z Q, J Chin Soc Corros Prot24 (2004) 2.

Leon C A, and Drew R A L, Compos Part A Appl Sci Manuf33 (2002) 1429.

Chen S G, Ding H F, and Zheng Z X, Surf Technol30 (2001) 3.

Liu Y C, ZhangY M, Rong D H, Zhao Y, Yin Y S, and Zuo T J, Ordnance Mater Sci Eng32 (2009) 24.

van Otterloo J L D M, Bagnoli D, and De Hosson J T M, Acta Metall Mater43 (1995) 2649.

Yan G, Zhou J E, and Wang Y F, Rare Metal Mater Eng35 (2006) 1621.

Acknowledgements

This work was financially supported by the Open Fund Key Laboratory of Oil & Gas Field Material (X151518KCL16) and Chongqing Science and Technology Bureau Fund (CSTC 2017JCYJA1012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Wang, L., Gao, X. et al. Study on Interface Behavior of SiC/SiO2/Al and SiC/Ni/Al. Trans Indian Inst Met 72, 3171–3178 (2019). https://doi.org/10.1007/s12666-019-01782-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01782-1