Abstract

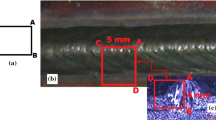

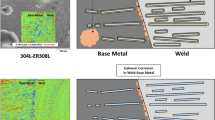

During welding of 316L stainless steel (SS), heat-affected zone (HAZ) is susceptible to sensitisation and fusion zone is susceptible to pitting corrosion in stainless steel welds. High-nitrogen electrodes with 0.045–0.055 wt% C and with different Cr contents were used for welding of prototype fast breeder reactor components. As-welded and thermally aged (823 K for 2 h) weldments of type 316LN SS with different N contents made by arc welding were studied for localised corrosion. ASTM A262 Practice A and E tests and double-loop electrochemical potentiokinetic reactivation studies on as-welded and thermally aged specimens revealed the absence of sensitisation in the HAZ and in fusion zone. However, pitting potential of the weldments was found to vary with the concentration of N + Cr + Mo in fusion zone and found to be lower in the thermally aged samples. The correlation between weld microstructure, alloying elements and pitting corrosion behaviour has been discussed.

Similar content being viewed by others

References

Dayal R K, Parvathavarthini N, and Raj B, Int Mater Rev50 (2005) 129.

Jayakumar T, Bhaduri A K, Mathew M D, Albert S K, and Kamachi Mudali U, Adv Mater Res794 (2013) 670.

Mannan S L, Chetal S C, Raj B, and Bhoje S B, in Proceedings of Seminar on Materials R&D for PFBR (2013).

Silva C C, Farias J P, and de Santana HB, Mater Des30 (2009) 1581.

Kumar S, and Sahi A S, Int J Comput Appl0975-8887 (2015) 1.

Garcia C, de Tiedra M P, Blanca Y, Martin O, and Martin F, Corros Sci50 (2008) 2390.

Unnikrishnan R, Idury K S, Ismail T P, Bhandari A, Shekhawat S K, Khatirkar R K, and Sapate S G, Mater Charact93 (2014) 10.

Pujar M G, Kamachi Mudali U, Dayal R K, and Gill T P S, Corrosion48 (1992) 579.

Kamachi Mudali U, Hasan Shaikh A R, and Dayal R K, Intergranular Corrosion Behaviour of Type 316LN Weldments, NWS (1997) 1.

Kamachi Mudali U, and Dayal R K, Mater Sci Technol16 (2000) 1.

Baeslack W A, Savage W F, and Duquette D J, Weld J Res Suppl (1979) 83.

Albert S K, and Bhaduri A K, Research and Development in Welding and Hard Facing Towards Construction of Prototype Fast Breeder Reactor, 38th MPA-Seminar, October 1–2, 2012, Stuttgart 195.

Li L, Chai M, Li Y, Bai W, and Duan Q, Appl Mech Mater331 (2013) 578.

Vijayanand V D, Laha K, Parameswaran P, Ganesan V, and Mathews M D, Mater Sci Eng A 607 (2014) 138.

Streitcher M A, Theory and Application of Evaluation Test for Detecting Susceptibility to Intergranular Attack in Stainless Steels and Related Alloys-Problems and Opportunities, ASTM STP 656, American Society for Testing and Material, Philadelphia (1975), p 70.

Marttivilpass, Prediction of Micro Segregation and Pitting Corrosion Resistance of Austenic Stainless Steel Welds by Modeling. Doctor of Science in Technology Thesis, Helsinki University (1999) p 1–166.

Kamachi Mudali U, Dayal R K, Gill T P S, and Gnanamoorthy J B, Werkstoffe Corros37 (1986) 637.

Pujar M G, Parvathavarthini N, Dayal R K, Mater Chem Phys123 (2010) 407.

Toppo A, Pujar M G, Sreevidya N, and Philip J, Def Technol14 (2018) 226.

Poonguzhali A, Pujar M G, and Kamachi Mudali U, J Mater Eng Perform49 (1993) 977.

Ogawa T, Aoki S, Sakamoto T, and Zaizen T, The Weldability of Nitrogen Containing Austenitic Stainless Steel: Chloride Pitting Corrosion Resistance. Missouri (1982) p 139.

Ferrar R A, Hulen C, and Thomas R G, J Mater Sci20 (1985) 2828.

Suuatala N, Metall Trans A144 (1983) 191.

Delong W T, Weld J53 (1974) 2735.

Koteck D J, and Siewert T A, Weld J71 (1992) 1715.

Parvathavarthini N, Dayal R K, Kathak H S, Shankar V, and Shanmugan V, J Nucl Mater355 (2006) 68.

Toppo A, Pujar M G, Arivazahagan B, Vasudevan M, Mallika C, and Kamachi Mudali U, Corrosion514 (2016) 295.

Basu K, Das M, Bhattacharjee D, and Chakraborti P C, Mater Sci Technol23 (2007) 1278.

ASTM A262-14, Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels, ASTM International, USA (2014).

David S A, Ferrite Morphologhy and Variations in Ferrite Content in Austenitic Stainless Steel Welds, Cleveland, Ohio (1981) p 63.

Takalo T, Suutula N, and Moiso T, Metall Trans A10 (1979) 1173.

Ghosh S K, Jha S, Mallick P, and Chattopadhyay P P, Mater Manuf Process28 (2013) 249.

Aydogdu G H, Determination of Susceptibility to Intergranular Corrosion in 304L & 316L Type Stainless Steels by Electrochemical Reactivation Method, Degree of Master of Science Thesis, Middle East Technical University (2004) p 1.

Muraleedharan P, Gnanamoorthy J B, and Prasad Rao K, Corrosion45 (1989) 142.

Parvathavarthini N, and Dayal R K, J Nucl Mater399 (2010) 62.

Mozhi T A, Clark W A T, Nishimoto K, Jhonson W B, and Mac Donald D D, Corrosion41 (1985) 555.

Frankel G S, J Electrochem Soc145 (1998) 2186.

Szklarska-Smialowska Z, Corrosion27 (1971) 223.

Raja V S, Corros Rev21 (2003) 1.

ASTM G102-89, Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements, ASTM International, USA, 2014.

Acknowledgement

The authors would like to thank Dr A.K. Bhaduri, Director, IGCAR, for his constant support and encouragement and Smt. P. Sundari, CSTD/MMG, IGCAR, for providing experimental support during the investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mannepalli, S., Ravi Shankar, A., George, R.P. et al. Pitting Corrosion Studies on Fusion Zone of Shielded Metal Arc Welded Type 316LN Stainless Steel Weldments. Trans Indian Inst Met 72, 3089–3105 (2019). https://doi.org/10.1007/s12666-019-01775-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01775-0