Abstract

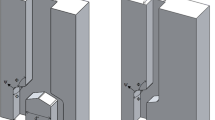

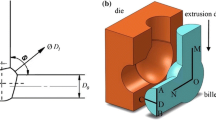

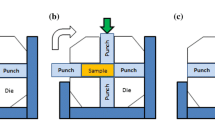

Equal channel angular pressing (ECAP) is currently the most widely used severe plastic deformation (SPD) process. The current work presents a validated finite element modelling for a new SPD process named “non-equal channel multi-angular extrusion (NECMAE)”. NECMAE is combined of two stages; the first stage is a standard ECAP, while the second stage experiences a reduction in cross-sectional area. The effects of different reduction in area—in NECMAE—on material plastic deformation, corner gap, stress distribution and required load were examined. In addition, a mathematical model was developed in order to trace the shear strains imposed on the material at different stages. Cases with higher reduction in area were found to have smaller corner gap, higher and uniform plastic deformation, as well as higher loads. The magnitude of maximum stresses was unaffected by different designs; the shape and size of the highly stressed material varied with die design. The current results were explained in terms of; (1) back pressure; (2) strain hardening; (3) shear angle of the second stage; and (4) shear strain history.

Similar content being viewed by others

References

Segal V M, Reznikov V I, Drobyshevskii A E, and Kopylov V I, Plastic Metal Working by Simple Shear. Izv Akad Nauk SSSR Met (1981) 115. http://www.scopus.com/inward/record.url?eid=2-s2.0-0019392095&partnerID=40&md5=0e4f3b3572a2c0a92dcf8d4cae3b5629.

El-Danaf E A, Soliman M S, Almajid A A, and El-Rayes M M, Mater Sci Eng A 458 (2007) 226 https://doi.org/10.1016/j.msea.2006.12.077.

El-Asfoury M S, Nasr M N A, Nakamura K, and Abdel-Moneim A, J Electron Mater 47 (2018) 242. https://doi.org/10.1007/s11664-017-5755-7.

Furukawa M, Horita Z, and Langdon T G, Mater Sci Eng A 332 (2002) 97. https://doi.org/10.1016/s0921-5093(01)01716-6.

R M R, Venkatraman R, Raghuraman S, and Forging S P, Int J Recent Res Appl Stud 12 (2012) 477.

Soltantabar M, Krishnaiah D A, and Tari A, IOSR J Mech Civ Eng 10 (2014) 01. https://doi.org/10.9790/1684-1060105.

Mazurina I, Sakai T, Miura H, Sitdikov O, and Kaibyshev R, Mater Sci Eng A 473 (2008) 297. https://doi.org/10.1016/j.msea.2007.04.112.

Altan B, Severe Plastic Deformation: Toward Bulk Production of Nanostructured Materials, Nova Science, Hauppauge (2006).

Ramulu P J, Lavanya A, Design and Fabrication of Equal Channel Angular Extrusion Process Analysis for Non-ferrous Materials, Anchor Academic Publishing, Hamburg (2017).

Iwahashi Y, Wang J, Horita Z, Nemoto M, and Langdon T G, Scr Mater 35 (1996) 143. https://doi.org/10.1016/1359-6462(96)00107-8.

Dobatkin S, Investigations and Applications of Severe Plastic Deformation, Lowe T C, Valiev R Z (eds) nATo Science Series (2000). http://scholar.google.com/scholar?hl=en&btnG=Search&q=intitle:Investigations+and+Applications+of+Severe+Plastic+Deformation+NATO+Science+Series#1 (accessed November 10, 2014).

Eivani A R, Ahmadi S, Emadoddin E, Valipour S, and Karimi Taheri A, Comput Mater Sci 44 (2009) 1116. https://doi.org/10.1016/j.commatsci.2008.07.025.

Segal V M, Mater Sci Eng A 345 (2003) 36. https://doi.org/10.1016/s0921-5093(02)00258-7.

Eivani A R, and Karimi Taheri A, J Mater Process Technol 183 (2007) 148. https://doi.org/10.1016/j.jmatprotec.2006.09.020.

Lee J C, Seok H K, and Suh J Y, Acta Mater 50 (2002) 4005. https://doi.org/10.1016/s1359-6454(02)00200-8.

Ghazani M S, and Mosadeg B, J Adv Mater 2 (2014) 47. http://www.jmatpro.ir/article_4612_742.html (accessed November 10, 2014).

Gurăua G, Indian J 21 (2014) 253. http://nopr.niscair.res.in/handle/123456789/28983 (accessed November 10, 2014).

Furui M, Kitamura H, Anada H, and Langdon T G, Acta Mater 55 (2007) 1083. https://doi.org/10.1016/j.actamat.2006.09.027.

Nakashima K, Horita Z, Nemoto M, and Langdon T G, Acta Mater 46 (1998) 1589. https://doi.org/10.1016/s1359-6454(97)00355-8.

Hasani A, Tóth L S, Beausir B, J Eng Mater Technol 132 (2010) 031001. https://doi.org/10.1115/1.4001261.

El-Asfoury M S, Nasr M N A, and Abdel-Moneim A, Effect of friction on material behaviour in non-equal channel multi angular extrusion (NECMAE), in: 2016: p. 103. https://doi.org/10.2495/hpsm160101.

Surendarnath S, Sankaranarayanasamy K, and Ravisankar B, IOP Conf Ser Mater Sci Eng 63 (2014) 012011. https://doi.org/10.1088/1757-899x/63/1/012011.

Kim H, ABAQUS/CAE Tutorial: Analysis of an Aluminum Bracket, Online (2004) 1–18.

Balasundar I, Sudhakara Rao M, and Raghu T, Mater Des 30 (2009) 1050. https://doi.org/10.1016/j.matdes.2008.06.057.

Sharma S, Raghav A K, and Kumar S, AIP Conf Proc 9359 (2014) 112.

Kim H S, Seo M H, and Hong S I, Mater Sci Eng A 291 (2000) 86. https://doi.org/10.1016/s0921-5093(00)00970-9.

Li S, Bourke M A M, Beyerlein I J, Alexander D J, and Clausen B, Mater Sci Eng A 382 (2004) 217. https://doi.org/10.1016/j.msea.2004.04.067.

Cerri E, De Marco P P, and Leo P, J Mater Process Technol 209 (2009) 1550. https://doi.org/10.1016/j.jmatprotec.2008.04.013.

Acknowledgements

The authors gratefully acknowledge the Missions Sector—Egyptian Ministry of Higher Education for financially supporting the current research project. Also, they would like to thank the Japan International Cooperation Agency (JICA) for its continuous support to Egypt-Japan University of Science and Technology (E-JUST), Alexandria, Egypt.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El-Asfoury, M.S., Nasr, M.N.A. & Abdel-Moneim, A. Non-equal Channel Multi-Angular Extrusion (NECMAE): A Design for Severe Plastic Deformation—Proof of Concept. Trans Indian Inst Met 72, 2827–2838 (2019). https://doi.org/10.1007/s12666-019-01759-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01759-0