Abstract

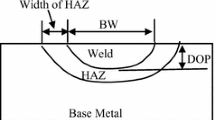

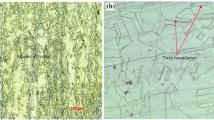

The aim of current work is to study the effect of different oxide fluxes in activated TIG welding process of dissimilar welding between LAFM and 316LN on weld dimensions, macro- and microexamination, and microhardness. Different oxide fluxes, namely TiO2, Fe2O3, CuO, Co3O4, and HgO, were used for the experiment, and its results were compared with convention TIG welding. Flux paste was applied over the area to be welded using a paint brush at the middle portion of the specimen. All welding experiments were carried out on a bead on a plate and under the same welding conditions and parameters. The experimental result reveals that full-length penetration was achieved with the use of Co3O4 and TiO2 fluxes. This enhancement in depth of penetration is attributed to the reverse Marangoni effect and arc constriction mechanism. In this study, insight was also revealed pertaining to the depth-enhancing mechanism present during ATIG welding of LAFM and SS316LN joints.

Similar content being viewed by others

References

Kurtz R J, Alamo A, Lucon E, Huang Q, Jitsukawa S, Kimura A, Klueh R, Odette G R, Petersen C, and Sokolov M A, J Nucl Mater 386 (2009) 411.

Activivty D R D, in IFERC, Rokasho, Aomori Japan (2013)

Aubert P, Tavassoli F, Rieth M, Diegele E, and Poitevin Y, J Nucl Mater 417 (2011) 43.

Manugula V L, Rajulapati K V, Madhusudhan Reddy G, Mythili R, and Bhanu Sankara Rao K, Metall Mater Trans A 48 (2017) 3702.

Manugula V L, Rajulapati K V, Reddy GM, Rajendra Kumar E, and Rao K B, Sci Technol Weld Join 23 (2018) 666.

Albert S K, Das C R, Sam S, Mastanaiah P, Patel M, Bhaduri A, Jayakumar T, Murthy C, and Kumar R, Fus Eng Des 89 (2014) 1605.

Vora J J, in Advances in Welding Technologies for Process Development, (eds) Vora J J, and Badheka V J, vol 1. CRC Press, Taylor and Francis (2019), p 23. https://doi.org/10.1201/9781351234825-11

Vora J J (2017) Development of Flux Assisted Tungsten Inert Gas Welding Process for Low Activation Ferritic Martensitic Steel. Pandit Deen Dayal Petroleum University, Gandhinagar.

Vaishnani S, Sadhu J, Suthar S, Vora J J, and Patel V (2017), Paper presented at the 4th International Conference on Industrial Engineering (ICIE 2017), Surat, Gujarat.

Naik A, Kundal D, Suthar S H, Vora J J, Patel V V, Das S, and Patel R, in Technology Drivers: Engine for Growth Proceedings of the 6th NIRMA University International Conference on Engineering (NUICONE 2017), November 23–25, 2017, Ahmedabad, India, (eds) Mahajan A, Modi B A, and Patel P, vol 1. CRC press, Taylor & Francis (2018), p 243.

Raj B, Vijayalakshmi M, Sivaprasad P, Panigrahi B, and Amarendra G, Indira Gandhi Centre for Atomic Research Kalpakkam (2008).

Vijaya L, Manugula K V R, Madhusudhan Reddy G, Mythili R, and Bhanu Sankara Rao K, Mater Des 92 (2016) 200.

Vidyarthy R, Kulkarni A, and Dwivedi D, Mater Sci Eng A 695 (2017) 249

Fuzeau J, Vasudevan M, and Maduraimuthu V, Trans Indian Inst Met 69 (2016) 1493.

Hicken G K, Campbell R D, Daumeyer G J, Madigan R B, Young B, and Marburger S J, In: AWS Welding Handbook, American Welding Society, USA (1997), p 74.

Shyu S, Huang H, Tseng K, and Chou C, J Mater Eng Perform 17 (2008) 193.

Nayee S G, and Badheka V J, J Manuf Process 16 (2014) 137.

Tseng K-H, and Hsu C-Y, J Mater Process Technol 211 (2011) 503.

Vora J J, and Badheka V J, Trans Indian Inst Met 69 (2016) 1755.

Vora J J, and Badheka V J, J Manuf Process 20 (2015) 224.

Vora J J, and Badheka V J, J Manuf Process 25 (2017) 85. https://doi.org/10.1016/j.jmapro.2016.11.007.

Vora J J, and Badheka V J, Int J Adv Mech Automob Eng 3 (2016) 5. http://dx.doi.org/10.15242/IJAMAE.AE0316011.

Dhandha K H, and Badheka V J, J Manuf Process 17 (2015) 48.

Arivazhagan B, and Vasudevan M, J Manuf Process 16 (2014) 305.

Chern T-S, Tseng K-H, and Tsai H-L, Mater Des 32 (2011) 255.

Kumar V, Lucas B, Howse D, Melton G, Raghunathan S, and Vilarinho L, in JOM-15-Fifteenth International Conference on the Joining of Materials (2009), p 1.

Kou S, Limmaneevichitr C, and Wei P S, Weld J 90 (2011) 229-S

Berthier A, Paillard P, Carin M, Valensi F, and Pellerin S, Sci Technol Weld Join 17 (2012) 609.

Mills K C, Keene B J, Brooks R F, and Shirali A, Philos Trans R Soc Lond A 356 (1998) 911.

Yang C, Lin S, Liu F, Wu L, and Zhang Q, J Mater Sci Technol 19 (2003) 225.

Lin K-H, and Ta P-Y, Materials 7 (2014) 4755.

Lucas W, Weld Met Fabr 68 (2000) 7.

Acknowledgements

Authors would like to thank PDPU, Gandhinagar, for the utilization of the ATIG welding facility available at Welding Research Laboratory, and SoT and GEC, Gandhinagar, for their microhardness testing facility. Authors would also like to extend their gratitude to the kind and sincere reviewers for enhancing the quality of papers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Patel, N.P., Badheka, V.J., Vora, J.J. et al. Effect of Oxide Fluxes in Activated TIG Welding of Stainless Steel 316LN to Low Activation Ferritic/Martensitic Steel (LAFM) Dissimilar Combination. Trans Indian Inst Met 72, 2753–2761 (2019). https://doi.org/10.1007/s12666-019-01752-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01752-7