Abstract

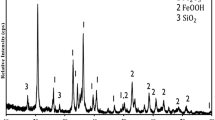

Iron ore washing plants generate slimes in significant volumes, which need to be treated for meeting the raw material demand as well as environmental mitigation. Selective flocculation, an emerging fines beneficiation route, has been chosen for the upgradation of Barsua iron ore slimes. Characterization studies revealed that the sample consists of 52.6% Fe, 3.8% SiO2, 7.4% Al2O3 and 6.7% LOI with hematite and goethite as the major iron-bearing minerals, intricately associated with quartz and kaolinite. Twin objectives of this study are: first to evaluate the selectivity of the polymer reagents for the desired mineral from the ore assemblage. Flocculation efficiency of starch and polyacrylamide (PAM) has been investigated. PAM has been found to be a better flocculant than starch for iron oxide minerals owing to the presence of chelating group in PAM structure, which is primarily responsible for advanced selective adsorption and formation of stable metal complexes. Second objective is adoption of factorial experimental design to assess the effects of process variables such as pH, pulp density and flocculant dosage on the selective flocculation of slimes. Process performance has been optimized to identify main and interactional effects using ANOVA statistical models. Successful upgradation has been envisaged with a Fe grade of 65.90% and recovery of 91.04% at optimized conditions of pH: 9, pulp density: 20% and flocculant dosage: 45 ppm, with a separation efficiency of 69.59%.

Similar content being viewed by others

References

Ore I, Indian Minerals Yearbook 2016 28 Iron Ore, 2016 (2018).

Jain V, Rai B, Waghmare U V, and Tammishetti V P, Trans Indian Inst Met 66 (2013) 447. https://doi.org/10.1007/s12666-013-0287-1.

Rocha L, Canado R Z L, and Peres A E C, Miner Eng 23 (2010) 842. https://doi.org/10.1016/j.mineng.2010.03.009.

Pearse M J, Miner Eng 18 (2005) 139. https://doi.org/10.1016/j.mineng.2004.09.015.

Panda L, Biswal S K, Venugopal R, and Mandre N R, Trans Indian Inst Met 71 (2018) 463. https://doi.org/10.1007/s12666-017-1177-8.

Banik R, Suresh N, and Mandre N R, Miner Process Extr Metall Rev 14 (1995) 169. https://doi.org/10.1080/08827509508914123.

Tripathy A, Bagchi S, Biswal S K, and Meikap B C, Chem Eng Res Des 117 (2017) 520. https://doi.org/10.1016/j.cherd.2016.11.009.

Das K K, and Somasundaran P, Colloids Surf A Physicochem Eng Asp 182 (2001) 25. https://doi.org/10.1016/s0927-7757(00)00735-4.

Somasundaran P, Das K K, and Yu X, Curr Opin Colloid Interface Sci 1 (1996) 530. https://doi.org/10.1016/s1359-0294(96)80123-3.

Weisseborn P K, Warren L J, and Dunn J G, Colloids Surf A Physicochem Eng Asp 99 (1995) 11. https://doi.org/10.1016/0927-7757(95)03111-p.

Friend J P, and Kitchener J A, Chem Eng Sci 28 (1973) 1071. https://doi.org/10.1016/0009-2509(73)80010-7.

Moudgil B M, Mathur S, and Thatavarthy S P, KONA Powder Part J 15 (1997) 5. https://doi.org/10.14356/kona.1997006.

Hocking M B, Klimchuk K A, and Lowen S, J Macromol Sci Part C Polym Rev C39 (1999) 177. https://doi.org/10.1081/MC-100101419.

Moudgil B M, and Vasudevan T V, J Colloid Interface Sci 127 (1989) 239. https://doi.org/10.1016/0021-9797(89)90024-6.

Kitchener J A, Br Polym J 4 (1972) 217. https://doi.org/10.1002/pi.4980040307.

Attia Y A, Sep Sci Technol 17 (1982) 485. https://doi.org/10.1080/01496398208068553.

Tudu K, Pal S, and Mandre N R, Int J Miner Metall Mater 25 (2018) 498. https://doi.org/10.1007/s12613-018-1596-5.

Kumar R, and Mandre N R, Trans Indian Inst Met 69 (2016) 1459. https://doi.org/10.1007/s12666-015-0667-9.

Nanda D, Trans Indian Inst Met 71 (2018) 2985. https://doi.org/10.1007/s12666-018-1399-4.

Karmakar G P, and Singh R P, Colloids Surf A Physicochem Eng Asp 133 (1998) 119. https://doi.org/10.1016/s0927-7757(97)00129-5.

Ravishankar S A, Pradip, and Khosla N K, Int J Min Process 43 (1995) 235. https://doi.org/10.1016/0301-7516(95)00011-2.

Poorni S, and Natarajan K A, Colloids Surf B Biointerfaces 114 (2014) 186. https://doi.org/10.1016/j.colsurfb.2013.09.049.

Kumar S, Mandre N R, and Bhattacharya S, Trans Indian Inst Met 69 (2016) 1951. https://doi.org/10.1007/s12666-016-0853-4.

Acknowledgements

Authors are thankful to CRF-IIT (ISM) Dhanbad, CSIR-CIMFR Dhanbad and MRC-MNIT, Jaipur, for helping with characterization analyses. Authors would also like to acknowledge the Department of Fuel and Mineral Engineering for providing the platform to perform experiments and analyses.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumari, A., Gajbhiye, P. & Rayasam, V. Comparative Evaluation of Natural and Synthetic Flocculants on Selective Metal Recovery from Low-Grade Iron Ore Slimes. Trans Indian Inst Met 72, 2567–2579 (2019). https://doi.org/10.1007/s12666-019-01726-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01726-9