Abstract

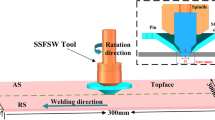

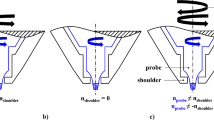

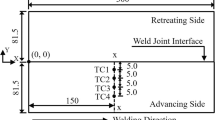

Considerable residual stress and distortion are inevitably produced by friction stir welding (FSW). An external stationary shoulder was applied to control and eliminate the residual stress and distortion of FSW joint. A thermo-mechanical model was utilized to analyze the effects of rotational velocities on temperature and stress distribution during welding. Results showed that the stationary shoulder provided synchronous rolling and intense cooling functions during welding, which reduced the peak residual tensile stress near the weld of FSW. The residual distortion of FSW joint was greatly reduced by the external stationary shoulder.

Similar content being viewed by others

References

Liu H J, Fujii H, Maeda M, and Nogi K, J Mater Process Technol 142 (2003) 692.

Simar A, Bréchet Y, Meester B D, Denquin A, and Pardoen T, Mater Sci Eng A 486 (2008) 85.

Aydin H, Durmuş A, Bayram A, and Sayaca T, Trans Indian Inst Met 65 (2012) 21.

Ma Z W, Jin Y Y, Ji S D, Meng X C, Ma L, and Li Q H, J Mater Sci Technol 35 (2019) 94.

Wang X H, and Wang K, Mater Sci Eng A 431 (2006) 114.

Dinaharan I, Murugan N, and Parameswaran S, Trans Indian Inst Met 65 (2012) 159.

Lombard H, Hattingh D G, Steuwer A, and James M N, Mater Sci Eng A 501 (2009) 119.

Long T, Tang W, and Reynolds A P, Sci Technol Weld Join 12 (2007) 311.

Riahi M, and Nazari H, Int J Adv Manuf Technol 55 (2011) 143.

Giorgi M D, Scialpi A, Panella F W, and Filippis L A C D, J Mech Sci Technol 23 (2009) 26.

Tufaro L N, Burgueno A, and Svoboda H G. Soldagem Insp 17 (2012) 327.

Ji S D, Yang Z P, Wen Q, Yue Y M, and Zhang L G, High Temp Mater Process 37 (2018) 397.

Kim Y G, Fujii H, Tsumura T, Komazaki T, and Nakata K, Mater Sci Eng A 415 (2006) 250.

Richter-Trummer V, Suzano E, Beltrão M, Roos A, and Santos J F D, Mater Sci Eng A 538 (2012) 81.

Jiang X, Wynne B P, and Martin J, J Mater Sci Technol 34 (2018) 198.

Russell M J, Blignault C, Horrex N L, and Wiesner C S, Weld World 52 (2008) 12.

Li Z W, Yue Y M, Ji S D, Chai P, and Zhou Z L, Mater Des 90 (2016) 238.

Sun T, Roy M J, Strong D, Withers P J, and Prangell P B, J Mater Process Technol 242 (2017) 92.

Li D X, Yang X Q, Cui L, He F Z, and Zhang X, J Mater Process Technol 222 (2015) 391.

Ji S D, Meng X C, Liu J G, Zhang L G, and Gao S S, Mater Design 62 (2014) 113.

Wang L, Davies C M, Wimpory R C, Xie L Y, and Nikbin K M, Mater High Temp 27 (2010) 167.

Cao X, and Jahazi M, Mater Des 30 (2009) 2033.

Wu C S, Zhang W B, Shi L, and Chen M A, Trans Nonferrous Met Soc 22 (2012) 1445.

Bachmann M, Carstensen J, Bergmann L, Dos Santos J F, Wu C S, and Rethmeier M, Int J Adv Manuf Technol 91 (2016) 1443.

Camilleri D, Micallef D, and Mollicone P, J Therm Stresses 38 (2015) 485.

Cozzolino L D, Coules H E, Colegrove P A, and Wen S, J Mater Process Technol 247 (2017) 243.

Deng D, and Murakawa H, Comput Mater Sci 43 (2008) 681.

Acknowledgements

This work was supported by “the National Natural Science Foundation of China (No.51705339), the Education Department Foundation of Liaoning Province (No. L201615) and the Science Foundation of State Key Laboratory of Robotics (No. 2016-007)”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, W., Li, M., Song, Q. et al. Efficacy of External Stationary Shoulder for Controlling Residual Stress and Distortion in Friction Stir Welding. Trans Indian Inst Met 72, 1349–1359 (2019). https://doi.org/10.1007/s12666-019-01630-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01630-2