Abstract

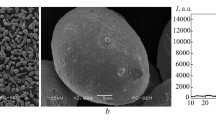

A NiCrBSi alloy coating was sprayed on H13 hot work mould using a high velocity oxygen fuel. The surface and cross-section morphologies of obtained NiCrBSi coating were observed using a field emission scanning electron microscope (SEM), its phases were analyzed using an X-ray diffractometer (XRD). The friction-wear behaviors of NiCrBSi coating were investigated using a high temperature wear tester, the morphologies and chemical elements of worn tracks were analyzed using a SEM and its configured energy dispersive spectrometer (EDS), respectively. The results show that the average COF of NiCrBSi coating at 500, 600, and 700 °C is 0.4046, 0.4039, and 0.3975, respectively. The wear mechanism of NiCrBSi coating at 500 and 600 °C is abrasive wear, adhesive wear and oxidation wear, while that at 700 °C is abrasive wear and oxidation wear, the wear resistance of NiCrBSi coating is dependent on the compounds of Ni, Si and Cr.

Similar content being viewed by others

References

Jacobsen S D, Hinrichs R, Aguzzoli C, Figueroa C A, Baumvol I J R, and Vasconcellos M A Z, Surf Coat Technol 286 (2016) 129

Telasang G, Majumdar J D, Padmanabham G, and Manna I, Surf Coat Technol 261 (2015) 69

Wang Y B, Zhao S S, Gao W Y, Zhou C Y, Liu F L, and Lin X C, J Mater Process Technol 214 (2014) 899

Kong D J, and Zhao B G, J Alloys Compd 705 (2017) 700

Sidhu T S, Prakash S, and Agrawal R D, Mater Sci Eng A 445–446 (2007) 210

Sidhu T S, Prakash S, Agrawal R D, Yu H L, Zhang W, Wang H M, Yin Y L, Ji X C, and Zhou K B, J Alloys Compd 672 (2016) 137

Guo C, Chen J, Zhou J, Zhao J, and Wang L, Surf Coat Technol 206 (2012) 2064

Zhu L N, Xu B S, Wang H D, and Wang C B, Mater Sci Eng A 528 (2010) 425

Sidhu T S, Prakash S, and Agrawal R D, Thin Solid Films 515 (2006) 95

Zikin A, Antonov M, Hussainova I, Katona L, and Gavrilović A, Tribol Int 68 (2013) 45

Shabana, Sarcar M M M, Suman K N S, and Kamaluddin S, Mater Today Proc 2 (2015) 2654

Rodriguez J, Martín A, Fernández R, and Fernández JE, Wear 255 (2003): 950

Miguel J M, Guilemany J M, and Vizcaino S, Tribol Int 36 (2003) 181

Karaoglanli A C, Oge M, Doleker K M, and Hotamis M, Surf Coat Technol 318 (2017) 299

Houdková S, Smazalová E, Vostřák M, and Schubert J, Surf Coat Technol 253 (2014) 14

Guo C, Zhou J, Chen J, Zhao J, Yu Y, and Zhou H, Wear 270 (2011) 492

Shabana, Sarcar M M M, Suman K N S, and Kamaluddin S, Mater Today Proc 2 (2015) 2654

Zhu L N, Xu B S, Wang H D, and Wang C B, Mater Sci Eng A 536 (2012) 98

Luo X, Li J, and Li G J, J Alloys Compd 626 (2015) 102

Deschuyteneer D, Petit F, Gonon M, and Cambier F, Surf Coat Technol 283 (2015) 162

Jiang J, Stott FH, and Stack M M, Wear 256 (2004) 973

Pauschitz A, Roy M, and Franek F, Tribol Int 41 (2008) 584

Inman I A, Rose S R, and Datta P K, Tribol Int 39 (2006) 1361

Inman I A, and Datta P S, Tribol Int 44 (12) 1902

Zhou S F, Lei J B, Dai X Q, Guo J B, Gu Z J, and Pan H B, Int J Refract Met Hard Mater 60 (2016) 17

Acknowledgements

Financial support for this research by the Jiangsu Province Science and Technology Support Program (Industry) (BE2014818) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, W., Zhao, B. & Kong, D. Friction–Wear Characteristics of High Velocity Oxygen Fuel Sprayed NiCrBSi Alloy Coating at Elevated Temperatures. Trans Indian Inst Met 71, 2565–2573 (2018). https://doi.org/10.1007/s12666-018-1386-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1386-9