Abstract

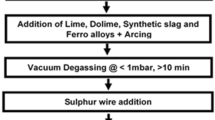

The behaviour of hydrogen during controlled industrial scale secondary steel making process has been examined in a variety of low alloy steels, sensitive to hydrogen flaking. The study examines the role played by the moisture in input raw materials such as the ferro-alloys, type of carbon additive and fluxes in enhancing the hydrogen content in the ladle furnace. Post alloying, the influence of vacuum degassing parameters such as the vacuum level, vacuum holding time, Ar flow rate, type of porous plug used, slag chemistry and the steel grade was examined. The vacuum degassing process was analysed using a kinetic model, which could justify the trends seen in the vacuum level, holding time and Ar gas flow rate. Finally, the hydrogen pick-up post vacuum degassing through slag cover and the casting tundish was found to be influenced by parameters such as the quality of the tundish spray mass, and casting sequence. The influence of steel grade in hydrogen removal was also examined.

Similar content being viewed by others

References

Ravichandar D, Balusamy T, and Nagashanmugam K B, Appl Mech Mater 591 (2014) 38.

Ravichandar D, Balusamy T, and Nagashanmugam K B, Indian J Eng Mater Sci 22 (2016), 283.

Ravichandar D, Balusamy T, and Nagashanmugam K B, J Chem Technol Metall 51 (2016), 328.

Abijit N, IIM Metal News 12 (2009) 17.

Turkdogan E T, and Fruehan R J, Fundamentals of Steelmaking, Maney Publishing, Leeds (1996) p 96257.

Fruehan R J, Vacuum Degassing of Steel, Iron and Steel Society/AIME, Warrendale (1990) p 212.

Bradshaw A V, and Richardson F D, Thermodynamic and Kinetic Aspects of Vacuum Degassing. Special Report, 92 (1965).

Fruehan R J, and Misra S, EERE Publication and Product Library (2005).

Lange K W, Int Mater Rev 33 (1988), 53.

Bannenberg N, Bergmann B, and Gaye H, Steel Res Int 63 (1992), 431.

Yu S, and Louhenkilpi S, Metall Mater Trans B 44 (2013), 459.

Yu S, Miettinen J, and Louhenkilpi S, Int Mater Sci Forum 762 (2013), 253.

Steneholm K, Andersson M, Tilliander A, and Jonsson P G, Ironmak Steelmak 40 (2013), 199.

Baragiola S, Unamuno I, Sormann A, Pena Quintero B, Lovicu G F, Niska J, Kajberg J, and Kytonen H, European Commission, Research Fund for Coal and Steel, EUR 26397 EN (2012).

Gobinath R, M. Tech Thesis, Indian Institute of Technology Bombay (2015). http://etd.library.iitb.ac.in//data/13/meta/mtech/133114007/abstract.html.

Fera S, Osta A, Idoyaga Z, Albarran J, Molinero J, Valleggi R, and Sormann A, Technical Steel Research, EU, EUR 22435 EN, Contract No. 7210-PR/357 (2005) p 51.

Sigworth G K, and Elliott J F, Met Sci 8 (1974) 298.

Wang H, Viswanathan N N, and Ballal N B and Seetharaman S, Int J Chem React Eng 8 (2010) 1.

Acknowledgements

The authors thank Mr. G. Murali and team from Steel Melting Shop for conducting the various trials as per requirement. The authors thank Mr. S. M. Kumar and team from Quality Assurance Department for conducting the various analysis. The support accorded by senior management to conduct this research is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravichandar, D., Balusamy, T., Gobinath, R. et al. Behaviour of Hydrogen in Industrial Scale Steel Melts. Trans Indian Inst Met 71, 2505–2515 (2018). https://doi.org/10.1007/s12666-018-1381-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1381-1