Abstract

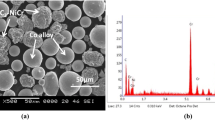

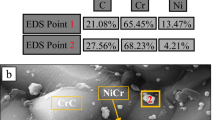

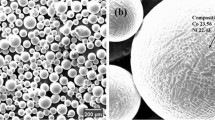

This paper investigates cyclic hot corrosion of plasma sprayed CoCrAlY + Al2O3 + YSZ (C1) and CoCrAlY + CeO2 (C2) composite coatings on MDN 321 and Superni 76 substrates in molten salt (Na2SO4-60%V2O5) environment exposed to 700 °C. Weight change technique is used to evaluate the corrosion performance. Both C1 and C2 coatings showed better corrosion resistance than uncoated alloy. Both the coatings showed linear weight gain during the initial cycles and parabolic weight gain nature with subsequent hot corrosion cycles. The parabolic rate constant (Kp) of C1 and C2 coating was observed to be in the range 0.29–0.32 × 10−10 g2 cm−4 s−1 and 1.0–1.13 × 10−10 g2 cm−4 s−1 respectively. In C1 coating, the globular and continuously packed structure on the corroded surface having CoO, Cr2O3, CoCr2O4 and CoAl2O4 spinel oxides provided superior hot corrosion resistance. While in case of C2 coating, the outward growth of CeVO4 irregular crystals as a corrosion product of CeO2 and V2O5 salt deteriorated the oxide scales resulting in higher corrosion rate.

Similar content being viewed by others

References

James W, and Rajagopalan S, Structural Alloys for Power Plants, (ed) Shirzadi A, and Jackson S, Woodhead Publishing Series in Energy (2014), p 3.

Becker W T, and Shipley R J, ASM Metals Handbook: Vol. 11. Failure analysis and prevention, ASM Publication (2002), p. 1533.

Gurrappa I, Surf. Coat. Technol. 139 (2001) 272.

Doolabi D S, Rahimipour M R, Alizadeh M, Pouladi S, Hadavi S M, and Vaezi M R, Vacuum 135 (2017) 22.

Ramesh M R, Prakash S, Nath S K, Sapra P K, and Venkataraman B, Wear 269 (2010) 197.

Lu J, Zhu S, Wang F, Surf. Coat. Technol. 205 (2011) 5053.

Cai J, Yang S Z, Ji L, Guan Q F, Wang Z P, and Han Z Y, Surf. Coat. Technol. 251 (2014) 2017.

Utu I D, Marginean G, Hulka I, Serban V A, Cristea D, Int. J. Refract. Met. Hard Mater. 51 (2015) 118.

Eliaz N, Shemesh G, and Latanision R M, Eng. Fail. Anal. 9 (2002) 31.

Baiamonte L, Marra F, Gazzola S, Giovanetto P, Bartuli C, Valente T, and Pulci G, Surf. Coat. Technol. 295 (2016) 78.

Nicholls J. R, Simms N J, Chan W Y and Evans H E, Surf. Coat. Technol. 149 (2002) 236.

Bolelli G, Candeli A, Lusvarghi L, Ravaux A, Cazes K, Denoirjean A, and Valette S, Wear 344 (2015) 69.

Cabral Miramontes J A, Gaona Tiburcio C, Almeraya Calderón F, Estupiñan Lopez F H, Pedraza Basulto G K, and Poblano Salas C A, Int. J. Corr (2014) 8.

Praveen A S, Sarangan J, Suresh S, and Subramanian J S, Int. J. Refract. Met. Hard Mater. 52 (2015) 209.

Kim H J, Hwang S Y, Lee C H, and Juvanon P, Surf. Coat. Technol.172 (2003) 262.

Ogawa K, Ito K, Shoji T, Seo D W, Tezuka H, and Kato H, J. Therm. Spray Technol. 15 (2006) 640.

Zhou X, and Ouyang C, Surf. Coat. Technol. 315 (2017) 67.

Wang Y, Yang Y, and Yan M F, Wear 263 (2007) 371.

Song B, Dong S, Liao H, and Coddet C, Surf. Coat. Technol. 268 (2015) 24.

He K, Chen J, Weng W, Li C, and Li, Q, Vacuum 151 (2018) 209.

Xiao J K, Zhang W, Liu L. M, Gan X P, Zhou K C, and Zhang C, Surf. Coat. Technol. 337 (2018) 159.

Otero E, Merino M C, Pardo A, Biezma M V, and Buitrago G, Proceedings of 10th ICMC 4 (1987) 3583.

Ramesh M R, Prakash S, Nath S K, Sapra P K and Krishnamurthy N, J. Therm. Spray Technol. 20 (2011) 992.

Somasundaram B, Kadoli R, and Ramesh M R, J. Therm. Spray Technol. 23 (2014) 1000.

McAlister A J, Alloy Phase Diagram, (ed) Hugh B, United States of America (1989), p 288.

Sampath S, Jiang X Y, Matejicek J, Leger A C, and Vardelle A, Mater. Sci. Eng. A 272 (1999) 181.

Zhu L, Zhu S, and Wang F, Appl. Surf. Sci. 268 (2013) 103.

Singh H, Kaur M, and Prakash S., J. Therm. Spray Technol. 6 (2016) 1192.

Luthra K L, J. Electrochem. Soc. 132 (1985) 1293

Zhang T, Huang C, Lan H, Du L, and Zhang W, J. Therm. Spray Technol. 6 (2016) 1208.

Afrasiabi A, Saremi M, and Kobayashi A, Mater. Sci. Eng. A 478 (2008) 264.

Jones R L, Williams C E and Jones A J, J. Electrochem. Soc. 133 (1986) 227.

Nejati M, Rahimipour M R, and Mobasherpou I, Ceram. Int. 40 (2014) 4579.

Ahmadi-Pidani R, Shoja-Razavi R, Mozafarinia R, and Jamali H, Mater. Des. 57 (2014) 336.

Afrasiab A, and Kobayashi A, Vacuum 88 (2013) 103.

Nithin H S, Desai V, and Ramesh M R, J. Mater. Eng. Perform. 26 (2017) 5251.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nithin, H.S., Desai, V. & Ramesh, M.R. Hot Corrosion Behaviour of Refractory and Rare Earth Oxide Reinforced CoCrAlY APS Coatings at 700 °C. Trans Indian Inst Met 71, 2403–2413 (2018). https://doi.org/10.1007/s12666-018-1371-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1371-3