Abstract

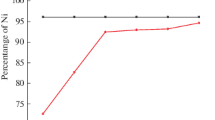

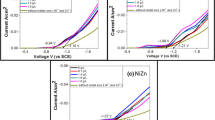

Zn and Zn–Ni alloy coatings were electrodeposited on mild steel from sulfate-based bath containing Sn as additive. The effect of Ni content on the microstructure, morphology, microhardness and the tribological behavior of these coatings were studied and discussed. Adding Sn in the sulfate bath had a significant effect on the surface morphology, particularly on the Zn–8 wt% Ni coatings. By increasing the Ni concentration from 8 to 14 wt%, the X-ray patterns showed that the phase structure of Zn–Ni alloy coatings was changed from η-phase Ni3Zn22 to γ-phase Ni5Zn21. The plastic deformation and delamination were found to be wear mechanisms for the investigated coatings. While the Zn–14 wt% Ni alloys had the best wear resistance, Zn films had the most severe wear volume loss and the highest friction coefficient.

Similar content being viewed by others

References

Marder A, Progr Mater Sci 45 (2000) 191.

Panagopoulos C N, Lagaris D A, and Vatista P C, Mater Chem Phys 126 (2011) 398.

Boshkov N, Electrochim Acta 51 (2005) 77.

Wasekar N P, Jyothirmayi A, Hebalkar N, and Sundararajan G, Surf Coat Technol 272 (2015) 373.

Ibrahim S, Bakkar A, Ahmed E, and Selim A, Electrochim Acta 191 (2016) 724.

Zelger C, Laumen J, Laskosb A, and Gollas B, Electrochim Acta 213 (106) 208.

Fratesi R, Roventi G, Giuliani G, and Tomachuk C R, J. Appl Electrochem 27 (1997) 1088.

Karahan I H, and Guder H S, Trans Inst Met Finish 87 (2009) 155.

Hall D E, Plat Suf Finish 70 (1983) 59.

Felloni L, Fratesi R, Quadrini E, and Roventi G, J Appl Electrochem 17 (1987) 574.

Mathias M F, and Chapman T W, J Electrochem Soc 134 (1987) 1408.

Albalat R, Gomez E, Muller C, Sarret M, Valles E, and Pregonas J, J Appl Electrochem 20 (1990) 635.

Younan M M, J Appl Electrochem 30 (2000) 55.

Bajat J B, Petrovic A B, and Maksimovic M D, J Serb Chem Soc 70 (2005) 1427.

Hsu G F, Plat Surf Finish 71 (1984) 52.

Roventi G, Bellezze T, and Fratesi R, Electrochim Acta 51 (2006) 2691.

Conde A, Arenas MA, and De Damborene J J, Corros. Sci 53 (2011) 1489.

Ghaziof S, and Gao W, Appl Surf Sci 311 (2014) 635.

Tozar A, and Karahan I H, Appl Surf Sci 318 (2014) 15.

Feng Z, Li Q, Zhang J, Yang P, Song H, and An M, Surf Coat Technol 270 (2015) 47.

Yogesha S, and Chitharangan Hedge A, Trans Ind Inst Met 63 (2010) 841.

ASTM. 2006 F1941-00 Standard Specification for Electrodeposited Coatings on Threaded Fasteners (Unified Inch Screw Threads (UN/UNR). ASTM International, West Conshohocken, PA, 19428-2959, https://doi.org/10.1520/f1941-07. www.astm.org.

Sriraman K R, Strauss H W, Brahimi S, Chromik R R, Szpunar J A, Osborne J H, and Yue S, Surf Coat Technol 56 (2012) 107.

Panagopoulos C N, Georgarakis K G, and Agathocleous P E, Tribol Int 36 (2003) 619.

Tafreshi M, Allahkaram S R, and Farhangi H, Mater Chem Phys 183 (2016) 263.

Carpentier L, Caractérisation micromécanique de matériaux composites et anisotropes par indentation instrumentée. Thesis, Ecole Centrale de Lyon (1994).

Alfantazi A M, Page J, and Erb U, J Appl Electrochem 26 (1996) 1225.

Qiao X, Li H, Zhao W, and Li D, Electrochim Acta 89 (2013) 771.

Devanathan M A V, Stachurski Z, and Beck W, J Electrochem Soc, 111 (1964) 619.

Bockris J O M, and Koch D F A, J Phys Chem, 65 (1961) 1941.

Alfantazi A M, and Erb U, Mater Sci Eng A 212 (1) (1996) 123.

Archard J F, Appl Phys 24 (1953) 981.

Acknowledgements

The authors gratefully acknowledge the help and support of Professor Mongi Feki from the Laboratory of Materials Engineering and Environment (National Engineering School of Sfax; Sfax; Tunisia).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nasri, F., Zouari, M., Kharrat, M. et al. Structural, Micromechanical and Tribological Characterization of Zn–Ni Coatings: Effect of Sulfate Bath Composition. Trans Indian Inst Met 71, 1827–1840 (2018). https://doi.org/10.1007/s12666-018-1315-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1315-y