Abstract

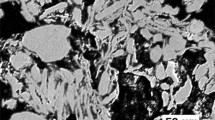

Carbon in various forms (such as fibers, fabrics, sheet, nano tubes, particles and flakes etc.) have found use as reinforcements in metal matrix composites (MMCs) based on aluminium alloys. However, the literature available on AA7075 alloy based composites as well as on the use of milled carbon fibers as reinforcements is rather limited. This was the stimulus for the present work on carbon fiber reinforced AA7075 alloy composites. MMCs with varying volume content of milled carbon fibers were fabricated through Vacuum hot pressing, and were characterized for mechanical, thermal and electrical properties. Micro-structural aspects of these MMCs were studied using Optical microscopy, Scanning electron microscopy, transmission electron microscopy and X-ray diffraction. This was followed by a systematic assessment of the mechanical properties (viz., hardness and compression strength), and thermal and electrical conductivities. The influence of T7 heat treatment on the properties was also investigated. The composites thus produced exhibit uniform distribution of carbon fiber. No evidence has been found of the presence of aluminium carbide (Al4C3) in any of the specimens. While the mechanical properties and electrical conductivity decreases as the amount of carbon fiber increases, thermal conductivity registers an appreciable increase in the In-plane direction. This appears to be the specific advantage of these carbon fibers reinforced MMCs, and is likely to open newer uses for this class of light weight materials.

Similar content being viewed by others

References

Zhou C, and Ji G, Mater Des 63 (2014) 719.

Prieto R, Molina J M, Narciso J, and Louis E, Compos Part A 42 (2011) 1970.

Naji H, Zebarjad S M, and Sajjadi S A, Mater Sci Eng 486 (1–2) (2008) 413.

Tang Y, Liu L, Li W, Shen B, and Hu W, Appl Surf Sci 255 (2009) 4393.

Sanchez M, Rams J, and Urena A, Compos Part A 41 (2010) 1605.

Bhav Singh B, and Balasubramanian M, J Mater Process Technol 209 (2009) 2104.

Hajjari E, Divandari M, and Mirhabibi H, Mater Des 31 (2010) 2381.

Balaji V, Sateesh N, Manzoor Hussain M, Mater Today Proc 2 (2015) 3403.

Lee W-S, Sue W-C, Lin C-F, Compos Sci Technol 60 (2000) 1975.

Wu L-M, Wang W-H, Hsu Y-F, and Trong S, Mater Trans 48 (2007) 600.

Zhang J, Liu S, Lu Y, Dong Y, Li T, J Mater Process Technol 231 (2010), 366.

Chawla KK, Composite Materials Science and Engineering, Second Edition, Springer, Delhi (2012) p 102.

Baumli P, Sychev J, Budai I, and Kaptay G, Compos Part A, 44 (2013) 47.

Silvain J F, Veillere A, and Lu Y, J Phys Conf Ser 525 (2014) 012015.

Kurita H, Miyazaki T, Kawasaki A, Lu Y, and Silvain J-F, Compos Part A 73 (2015) 125.

Simancik E, Jangg G, Degischer H, J Phs IV 03 (1993) 1775.

Chen J K, Huang I S, Compos Part B 44 (2013) 698.

Salazar M A, Mater Sci Forum 519–521 (2006) 853.

Marsh F H, and Reinoso R, Activated Carbon, Elsevier Science & Technology Books, Amsterdam (2006), p 15.

Almadhoni K, and Khan S, Int J Curr Eng Technol 5 (2015) 2884.

Burger N, Laachachi A, Ferriol M, Lutz M, Toniazzo V, and Ruch D, Progr Polym Sci 61 (2016) 1.

Bhat G, Structure and Properties of High Performance Carbon Fibers, Woodhead publishing series in Textiles, No. 187, 63.

Wu Z, Trans Nonferrous Met Soc China 20 (2010) 2148.

Tao Z, Guo Q, Gao X, Liu L, Mater Des 33 (2012) 372.

Acknowledgements

This research was financially supported by ISRO-UoP Space Technology Cell, Savitribai Phule Pune University (Project No. 139/2013). The authors gratefully acknowledge the support given by Messrs.GKN Sinter Metals Pune, Dr.T.S.Mahata, Bhabha Atomic Research Center, Navi Mumbai. Messrs. Aditya Heat Treaters, Pune and Messrs. Technofour, Pune.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deshpande, M., Gondil, R., Murty, S.V.S.N. et al. Studies on 7075 Aluminium Alloy MMCs with Milled Carbon Fibers as Reinforcements. Trans Indian Inst Met 71, 993–1002 (2018). https://doi.org/10.1007/s12666-017-1233-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1233-4