Abstract

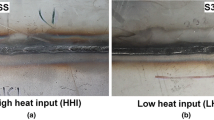

In the present research, microstructure and mechanical properties of 2205 duplex stainless steel/A517 quench and tempered low alloy steel dissimilar joint were investigated. For this purpose, gas tungsten arc welding was used with ER2209 filler metal. Characterizations were conducted by optical microscopy, scanning electron microscopy equipped with an energy dispersive spectroscopy and X-ray diffraction. Mechanical properties were evaluated in micro-hardness, tensile and impact tests. Microstructure in the weld zone included an austenitic continuous network in the matrix of primary ferrite. No brittle phases were formed in the weld metal and stainless steel heat affected zone (HAZ). The weld metal/A517 interface showed higher hardness than other regions. Tensile tests indicated that the values of the yield and tensile strength were 663 and 796 MPa, respectively. Impact tests indicated that the weld zone had almost the same impact energy as base metals. The minimum impact energy of 12 J was related to A517 HAZ. The results of scanning electron microscopy for fracture surfaces indicated that weld zone, 2205 HAZ and A517 HAZ had ductile, ductile–brittle and brittle fracture mode, respectively.

Similar content being viewed by others

References

Tavares S S M, Pardal J M, Lima L D, Bastos I N, Nascimento A M, and de Souza J A, Mater Charact 58 (2007) 610.

Udayakumar T, Raja K, Tanksale Abhijit A, and Sathiya P, J Manuf Process 15 (2013) 558.

Geng S, Sun J, Guo L, and Wang H, J Manuf Process 19 (2015) 32.

Tan H, Wang Z, Jiang Y, Yang Y, Deng B, Song H, and Li J, Corros Sci 55 (2012) 368.

Kotecki D J, and Lippold JC, Welding Metallurgy and Weldability of Stainless Steels, John Wiley, Hoboken, New Jersey (2005).

Yousefieh M, Shamanian M, and Arghavan M, Metallogr Microstruct Anal 1 (2012) 85.

Muthupandi V, Bala Srinivasan P, Seshadri S K, and Sundaresan S, Mater Sci Eng A 358 (2003) 9.

Luo J, Dong Y, Li L, and Wang X, J Manuf Process 16 (2014) 144.

Wang S, Ma Q, and Li Y, Mater Des 32 (2011) 831.

Wang S, Chiu P, Yang J, and Fang J, Mater Sci Eng A 420 (2006) 26.

Bala Srinivasan P, Muthupandi V, Dietzel W, and Sivan V, Mater Des 27 (2006) 182.

Sadeghian M, Shamanian M, and Shafyei A, Mater Des 60 (2014) 678.

Stainless T M R, Practical Guidelines for the Fabrication of Duplex Stainless Steels, International Molybdenum Association, London (2009).

Sieurin H, and Sandstrom R, Mater Sci Eng A 418 (2006) 250.

Eghlimi A, Shamanian M, Eskandarian M, Zabolian A, and Nezakat M, Surf Coat Technol 264 (2015) 150.

ASM Handbook, Welding, Brazing and Soldering 6, ASM International, Materials Park, Ohio (2004).

Kou S, Welding Metallurgy, John Wiley & Sons, Hoboken, New Jersey (2003).

Mourad A H I, Khourshid A, and Sharef T, Mater Sci Eng A 549 (2012) 105.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Foroughi, A., Shamanian, M., Kasiri-Asgarani, M. et al. Investigations on Dissimilar Weld of UNS S32205 DSS and ASTM A517 Steel. Trans Indian Inst Met 71, 533–544 (2018). https://doi.org/10.1007/s12666-017-1186-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1186-7