Abstract

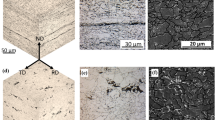

Steel grade AISI 5160, is a cost-effective straight chromium near eutectoid alloy steel used for several applications. The steel is used in thinner sections for application such as automotive leaf spring, knife etc. and in heavier section, the steel is used in applications such as wagon wheels, rails etc. The shallow hardenability of the steel generates a wide range of microstructures that influences the steel properties. The effect of normalizing, oil quenching and tempering was studied in a 140 mm thick round corner square (RCS) bar and 50 mm diameter bars of two different grain sizes. The microstructure evolution and its influence on the mechanical properties have been studied. The thicker 140 mm RCS bar showed pearlite in normalized and oil quenched condition. The pearlite in the oil quenched condition was extremely fine, resulting in superior mechanical properties. The 50 mm diameter bar with coarser grain size gave fully martensitic structure on oil hardening and a similar bar section with finer grain size showed the presence of pearlite in the matrix due to the influence of grain size on the hardenability. The study showed significant changes in microstructure as a function of section size, hardenability and heat treatment conditions. The study enabled proper choice of heat treatment for desired properties. The microstructure of other shallow hardenable near eutectoid steel was expected to show similar effect.

Similar content being viewed by others

References

Aher V K, and Sonawane P M, Int J Eng Res Appl 2 (2012) 51786.

Ghosh Chowdhary S, in Proceedings of COFA (1997) p 47.

Umemoto M, Komatsubara N, and Tamura I, ISIJ 53 (1979) 400.

Bain E G, J Heat Treat 1 (1932) 57.

Digges T C, Research Paper RP1308 24 (1940) 723.

Grange R A, Metal Trans A 4 (1973) 2231.

Sushanthi N, and Maity J, Metal Trans A 45A (2014) 6360.

Woodard P R, Chandrasekar S, and Yang H T Y, Metal Trans B 30B (1999) 815.

Kasatkin O G, Vinokur B B, and Pilyushenko V L, Metal Sci Heat Treat 26 (1984) 27.

Barralis J, Maeder G, Métall Tome I Métall Phys Collect Sci ENSAM (1982) 270.

Timken: Practical Data for Metallurgist: Jominy correlation with round bars, 15th Edition, p 54.

Hyzak J M, and Bernstein I M, Metal Trans A 7A (1976), 1217.

Acknowledgements

The authors wish to thank the constant encouragement and support provided by Dr Baba Kalyani, Chairman and Managing Director and Mr R K Goyal, Managing Director, Kalyani Carpenter Special Steels Pvt. Ltd., Pune. Authors would also thank Kalyani Centre for Technology and Innovation (KCTI) for their extended support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Perla, S., Kulkarni, S., Balachandran, G. et al. Influence of Section Size and Grain Size on the Microstructure Evolution and Mechanical Properties in Steel Grade AISI 5160. Trans Indian Inst Met 70, 2449–2458 (2017). https://doi.org/10.1007/s12666-017-1106-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1106-x