Abstract

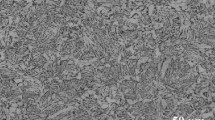

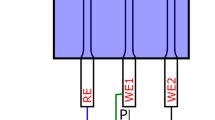

Degree of sensitization in 316LN stainless steel (SS) specimens sensitized at 898, 923 and 948 K for 500 h was obtained using double loop electrochemical potentiokinetic reactivation (DLEPR) technique as 7.4, 14.5 and 9.3% respectively. The sensitized specimens were pulsed polarized so that only Cr-depleted regions of the sensitized grain boundaries contributed to the electrochemical noise (EN) study. The DOS values evaluated from DLEPR technique were correlated with the EN parameters viz. standard deviation of current, σI and characteristic charge, q and characteristic frequency, f n , obtained from shot noise analysis in order to assess the extent of intergranular corrosion (IGC) attack in 316LN SS. The plot of σI versus time showed highest σI values for the specimen sensitized at 923 K for 500 h, indicating high grain boundary dissolution and hence, severe IGC attack, whereas the specimen sensitized at 898 K for 500 h showed the least σI values indicating lower dissolution and least IGC attack. 316LN SS specimen heat-treated at 948 K for 500 h showed intermediate grain boundary dissolution rate. The charge q, determined from σI versus time plot showed a good correlation (>99%) with the DOS values obtained from DLEPR experiments. The power spectral density values of the current signal in the frequency independent region were found to have excellent correlation with these observations. The above findings were further supported by scanning electron microscopic examination which showed an increase in grain boundary width in the sensitized specimens when the heat-treatment temperature was raised from 898 to 923 K and on further increasing the temperature to 948 K, a marginal decrease in the grain boundary width was observed.

Similar content being viewed by others

References

Ganesan V, Mathew M D, Parameswaran P, and Rao K B S, Trans Indian Inst Met 63 (2010) 417.

Parvathavarthini N, Kamachi Mudali U, Nenova L, Andreev C, and Raj B, Metall Mater Trans A 43 (2012) 2069.

Wasnik D, Kain V, Samajdar I, Verlinden B, and De P, Acta Mater 50 (2002) 4587.

Matula M, Hyspecka L, Svoboda M, Vodarek V, Dagbert C, Galland J, Stonawska Z, and Tuma, L, Mater Charact 46 (2001) 203.

Kamachi Mudali U, Ningshen S, Tyagi A, and Dayal R K, Trans Tech Publ (1999) 495.

Pujar M G, Kamachi Mudali U, Dayal R K, and Gill T, Corrosion 48 (1992) 579.

A262 A, ASTM International West Conshohocken, PA.

Cihal V, Desestret A, Froment M, and Wagner G, CETIM–Centre de Researches de Firminy, CAFL, Rapport (1969).

Novak P, Stefec R, and Franz F, Corrosion 31 (1975) 344.

Parvathavarthini N, and Kamachi Mudali U, Corros Rev 32 (2014) 183.

Pujar M G, George R, Muraleedharan P, and Kamachi Mudali U, Corrosion 67 (2011) 115004.

Pujar M G, Kamachi Mudali U, and Singh S S, Corros Sci 53 (2011) 4178.

Upadhyay N, Pujar M G, Das C R, Mallika C, and Kamachi Mudali U, Corrosion 70 (2014) 781.

Pujar M G, Toppo A, Shaikh H, Dayal R K, and Khatak H, J Mater Eng Perform 16 (2007) 494.

Toppo A, Pujar M.G, Mallika C, Kamachi Mudali U, and Dayal R.K, J Mater Eng Perform 24 (2015) 1140.

Pujar M G, Parvathavarthini N, Dayal R K, and Thirunavukkarasu S, Corros Sci 51 (2009) 1707.

Tsakova V, and Milchev A, Electrochim Acta 36 (1991) 1579.

Tsakova V, Milchev A, and Schultze J, J Electroanal Chem 346 (1993) 85.

Zhou H, Wen J, Ning X, Fu C, Chen J, and Kuang Y, Synth Met 157 (2007) 98.

Sayano R, and Nobe K, Corrosion 22 (1966) 81.

Parvathavarthini N, Dayal R K, and Gnanamoorthy J, J Nucl Mater 208 (1994) 251.

Kamachi Mudali U, Dayal R, Gnanamoorthy J, and Rodriguez P, Metall Mater Trans A 27 (1996) 2881.

Bertocci U, Huet F, Nogueira R, and Rousseau P, Corrosion 58 (2002) 337.

Cottis R, Corrosion 57 (2001) 265.

Sanchez-Amaya J, Cottis R, and Botana F, Corros Sci 47 (2005) 3280.

Cottis R, Al-Awadhi M, Al-Mazeedi H, and Turgoose S, Electrochim Acta 46 (2001) 3665.

Cottis R, and Turgoose S, Trans Tech Publ 192 (1995) 663.

Al-Mazeedi H, and Cottis R, Electrochim Acta 49 (2004) 2787.

Upadhyay N, Pujar M G, Sakthivel T, Mallika C, Laha K, and Kamachi Mudali U, Proc Eng 86 (2014) 606.

Haruna T, Morikawa Y, Fujimoto S, and Shibata T, Corros Sci 45 (2003) 2093.

Gusmano G, Montesperelli G, Pacetti S, Petitti A, D’Amico A, Corrosion 53 (1997) 860.

Hardon R G, Lambert P, and Page C L, Br Corros J 23 (1988), 225.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Upadhyay, N., Pujar, M.G., Mallika, C. et al. Correlation of Electrochemical Noise Parameters with Degree of Sensitization in AISI Type 316LN Stainless Steel. Trans Indian Inst Met 70, 2371–2379 (2017). https://doi.org/10.1007/s12666-017-1098-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1098-6