Abstract

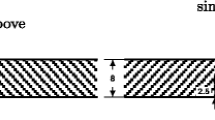

0.3 % C–CrMoV (ESR) steel has been proposed as an alternate cost effective material for fabrication of solid boosters for satellite launch vehicles. PAW studies on 7.8 mm thick 0.3 % C–CrMoV (ESR) steel have been conducted with filler wires of two different compositions. Welding parameters have been established for the steel. Welding has been carried out with stainless steel and copper back-up bars and effect of the same has been evaluated. Weldment has been characterized through optical microscopy, microhardness and mechanical properties evaluation. It is found that filler wire chemistry (low carbon content) does not significantly affect the properties of weldments subjected to post weld hardening and tempering treatment. It is attributed to low dilution in thicker plate welding and diffusion of carbon from base metal side during hardening treatment of the weldment. Use of different back- up bars also show similar results, except for process difficulties noted while using stainless steel. Weld efficiency >85 % has been observed with weldments having microhardness in the range of 480–520 VHN.

Similar content being viewed by others

References

Chatterjee M, Balasubramanian, M S N, Gupta K M, and Rao P K, J Ironmak Steelmak 17 (1990) 38.

Irving B, Weld J 74 (1995) 43.

Linnert G E, Welding Metallurgy, Vol. 2. 3rd Ed. American Welding Society, Miami (1967).

Seferian D, The Metallurgy of Welding, Wiley, New York (1962).

Coe F R, Welding Steels Without Hydrogen Cracking, The Welding Institute, Cambridge (1973).

Acknowledgments

We express our sincere thanks to DD, MME, VSSC for his constant encouragement and support. We are extremely thankful to the management and staff of M/s L&T, Powai for their valuable suggestions and help rendered during the course of the above studies. Thanks are also due to all our colleagues in VSSC for their support in heat treatment, machining, testing and characterization of the specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramkumar, P., Karthikeyan, M.K., Gupta, R.K. et al. Plasma Arc Welding of High Strength 0.3 % C–CrMoV (ESR) Steel. Trans Indian Inst Met 70, 1317–1322 (2017). https://doi.org/10.1007/s12666-016-0927-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0927-3