Abstract

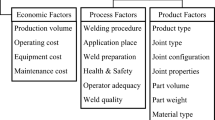

In this work we have shown that how combining the multi-criteria decision making (MCDM) process with fuzzy logic can be very efficient to solve decision problems in which there are criteria of different natures. This combination is applied here to solve a real decision problem of great interest in structural steel welding which is used widely in industry. The problem consists of selecting the best electric arc welding processes for a plate thickness greater than 12 mm. Because facing a decision problem of this type involves, on one hand, quantitative criteria (thermal efficiency, productivity, minimum power, etc.) and on the other hand, qualitative criteria (fatigue of welder, process learning, reliability, etc.), not only will it be necessary to apply a MCDM process, but it should also be combined with fuzzy logic with the aim of being able to perform the extraction of knowledge through a survey focused on experts. The Analytic Hierarchy Process has been used in order to obtain the weight of the criteria and, through the Technique for Order Preference by Similarity to Ideal Solution. The alternatives are also evaluated. There are no previous studies related to welding processes using the MCDM process with fuzzy logic.

Similar content being viewed by others

Abbreviations

- A− :

-

Negative ideal value set

- A+ :

-

Positive ideal value set

- Ai :

-

Best alternative

- AHP:

-

Analytic Hierarchy Process

- aij, bij, cij :

-

Fuzzy number

- Ci :

-

Criteria

- CI:

-

Consistency index

- cii :

-

Relative important of Ci–Ci

- cij :

-

Relative important of Cj–Cj

- CR:

-

Consistency ratio

- Ek :

-

Number of experts

- ELECTRE:

-

Elimination Et Choix Traduisant la Realité

- F-PROMETHEE:

-

Fuzzy Preference Ranking Organization Method for Enrichment Evaluations

- FCAW:

-

Flux cored arc welding

- GMAW:

-

Gas metal active welding

- GTAW:

-

Gas tungsten arc welding

- λ max :

-

Maximum eigenvalue

- m:

-

Amount of alternatives

- MAG:

-

Metal active gas

- MCDM:

-

Multi-criteria decision making

- MIG:

-

Metal inert gas

- n:

-

The size of the matrix C

- NIS:

-

Negative ideal solution

- PAW:

-

Plasma arc welding

- PIS:

-

Positive ideal solution

- PROMETHEE:

-

Preference ranking organization method of enrichement evaluations

- RI:

-

Random index

- Ri :

-

Ranking score

- SAW:

-

Submerged arc welding

- SMAW:

-

Shield metal arc welding

- TOPSIS:

-

Technique for order performance by similarity to ideal solution

- W:

-

Weight vector associated with the criteria

- wi :

-

The criterion Ci

- wj :

-

The criterion Cj

- xij :

-

Represent the performance score of alternative Ai against criteria Cj

References

DuPont J, and Marder A, Weld J Weld Res Suppl 74 (1995) 406.

Tušek J, Suban M, J Mater Process Technol 133 (2003) 207.

Meseguer-Valdenebro J L, MartÃ-nez-Conesa E J, Serna-Serrano J, and Portoles A, Therm Sci 20(2) (2016). doi:10.2298/TSCI140503106M.

Welding Handbook, Welding processes, 8th ed., vol. 2. AWS, USA (2001).

Mononen J, Sirén M and Hänninen H, Weld World 47 (2003) 11.

Kang M, Kim Y, Ahn S, and Rhee S, Weld J 82 (2003) 238S.

Kang M, and Rhee S, Weld. J 80 (2001) 1S.

EN B, Br Stand Inst (2001).

Satty TL and others, The Analytic Hierarchy Process, McGraw-Hill, New York (1980).

Hwang C and Yoon K, Multiple Attribute Decision Making: Methods and Applications, A State of the Art Survey. Springer, New York, 1981.

Roy B, Rairo-Oper Res-Rech Opérationnelle 2 (1968) 57.

Brins J and Vinke P, Manag Sci 31 (2002) 647.

Nikolic M, Jovanic D, Cockalo D, Djordjevic D, and Desnica E, Met Int 17 (2012) 51.

Park H, and Lee G, Development of Laser Welding System with Digital Manufacturing Technology, in Korus 2005, Proceedings, Pr Karla Marksa 20, 630092 Novosibirsk, Russia (2005) 625.

Ravisankar V, Balasubramanian V, and Muralidharan C, Mater Des 27 (2006) 373.

Balasubramanian V, Varahamoorthy R, Ramachandran C S, and Muralidharan C, Int J Adv Manuf Technol, 40 (2009) 887.

Yilmaz B, and Dağdeviren M, Expert Syst Appl 38 (2011) 11641.

Zadeh L A, Inf Control 8 (1965) 338.

Klir G, and Yuan B, Fuzzy sets and Fuzzy Logic, Prentice Hall, New Jersey (1995).

Zadeh L A, The Concept of a Linguistic Variable and its Application to Approximate Reasoning, Springer, Berlin (1974).

Zadeh L A, and Kacprzyk J, Computing with Words in Information/Intelligent Systems 2: Foundations, Springer Science & Business Media, Berlin (1999).

Zadeh L A, and Kacprzyk J, Computing with Words in Information/Intelligent Systems 1: Foundations, Springer Science & Business Media, Berlin (1999).

García-Cascales M S and Lamata M T, Pattern Recognit Lett, 28 (2007) 2284.

Bellman R E, Zadeh L A, Manag Sci 17 (1970) 141.

Kacprzyk J and Yager R R, Int J Gen Syst 30 (2001) 133.

Kerre E E, Approx Reason Decis Anal (1982) 277.

Sánchez-Lozano J, Dolón-Payán A, and Serna J, Aerosp Sci Technol (2015).

Saaty T L, Manag Sci, 36 (1990) 259.

Alonso J A, and Lamata M T, Int J Uncertain Fuzziness Knowl- Based Syst 14 (2006) 445.

Forman EH, Eur J Oper Res 48 (1990) 153.

Wang T C and Chang T H, Expert Syst Appl, 33 (2007) 870.

Garcia-Cascales M S, and Lamata M T, J Intell Manuf 22 (2011) 779.

Chen C T, Fuzzy Sets Syst 114 (2000) 1.

S.-J. J. Chen, C.-L. Hwang, M. J. Beckmann, and W. Krelle, Fuzzy multiple attribute decision making: methods and applications. Springer-Verlag New York, Inc., 1992.

Dutta P, Joshi Y, and Franche C, Exp Therm Fluid Sci 9 (1994) 80.

Niles R, and Jackson C, Weld J 54 (1975).

Chen J, Lu J, Li X and Zhang Y, Weld J 91 (2012) 9.

AWS Committee on Filler Metal, Ed., Specification for Tungsten and Tungsten-Alloy Electrodes for Arc Welding and Cutting. ANSI/AWS A5.12/A5.12 M-98. American Welding Society, USA (2005).

Atkins G, Thiessen D, Nissley N, and Adonyi Y, Weld J 81 (2002) 61S.

Garcia R P, and Scotti A, Soldag Inspecao 16 (2011) 146.

Gomes J H F, Costa S C, Paiva A P, and Balestrassi P P, J Mater Eng Perform 21 (2012) 1862.

Mostafa N, and Khajavi M, J Achieve Mater Man Eng 16 (2006) 1.

Nadzam J, Ed., GMAW Welding Guide. Lincoln Electric (2014).

AWS Committee on Filler Metal, Ed., Specification for Carbon Steel Electrodes and Rods for Gas Shield Arc Welding Arc Welding. AWS A5.18/A5.18 M. American Welding Society, USA (2005).

Houldcroft P T, Ed., Submerged-Arc Welding (Second Edition), Woodhead Publishing, Sawston 2 (1989) 87.

ASME International, Ed., Specification for Carbon Steel Electrodes and Fluxes for Submerged Arc Welding. SFA-5.17. American Welding Society, USA (2004).

Crespo A C, Scotti A, and Pérez M R, J Mater Process Technol, 199 (2008) 265.

AWS Committee on Filler Metal, Ed., Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding. ANSI/AWS A5.1-91. American Welding Society, USA (1991).

American Welding Society (AWS) A2 Committee on Definitions and Symbols, Standard Welding Terms and Definitions, 12th ed. AWS, USA (2010).

Caso A, Sistemas de incentivos a la producción Editor. Fund. Confemetal España (2003).

Mendez P F and Eagar T W, Adv Mater Process 159 (2001) 39.

Morrow L C, Maintenance Engineering Handbook, 2nd Ed Morrow LC (Ed.), Mcgraw-Hill, New York (1966).

Modenesi P, and De Avelar R, J Mater Process Technol, 86 (1999) 226.

Suban M, and Tušvsek J, J Mater Process Technol 119 (2001) 185.

Meseguer-Valdenebro J L, Serna J, Portoles A, Estrems M, Miguel V, and Martínez-Conesa E, Trans Indian Inst Met (2015) 1.

Capitanescu D, Press Vessel Technol 2 (1992) 1164.

Harris M K, Ewing W M, Longo W, DePasquale C, Mount M D, Hatfield R, and Stapleton R, J Occup Environ Hyg 2 (2005) 375.

Keeney R L and Raiffa H, Decisions with Multiple Objectives: Preferences and Value Trade-offs, Cambridge university press, Cambridge (1993).

Luce R D, and Raifa H, Games and Decisions-Introduction and Critical Survey, Wiley (1957).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sánchez-Lozano, J.M., Meseguer-Valdenebro, J.L. & Portoles, A. Assessment of Arc Welding Process Through the Combination of TOPSIS–AHP Methods with Fuzzy Logic. Trans Indian Inst Met 70, 935–946 (2017). https://doi.org/10.1007/s12666-016-0884-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0884-x