Abstract

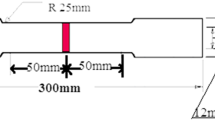

This paper presents the influence of the main parameters of the GMAW welding process on ingot iron sized 300 × 125 × 3 mm3, with a 1 mm separation between edges and without any bevel preparation. Three gases were used in this research: CO2, C15 and C25, with the purpose of studying the shielding influence of each of these gases separately in the welding process. In this research different power ranges were used with the purpose to assure the quality of the surface finish on the bead and the minimum penetration on the plates. The influence of the welding torch’s direction of advancement (forehand or backhand) for positions PA, PC and PE were studied together with its influence on the power source. The position which needed the least energy was the PA, followed by position PC and then position PE. The forehand advancement direction required more power than the backhand advancement direction for all positions. The influence of the gases from high to low on the width of the root bead and face bead was C15, CO2 and C25. This work would be useful to evaluate the influence of the welding parameters on a welding procedure specification with the GMAW welding process.

Similar content being viewed by others

Abbreviations

- ASME V:

-

American Standard Mechanical Engineers, section V

- AWS:

-

American Welding Society

- C15:

-

Gas 15 % CO2 + 85 % Ar

- C25:

-

Gas 25 % CO2 + 75 % Ar

- EN:

-

European norm

- GMAW:

-

Gas metal arc welding

- ISO:

-

International Organization of Standardization

- PA:

-

Flat position

- PC:

-

Horizontal position

- PE:

-

Overhead position

- PA-back:

-

Backwards welding advance in position PA

- PA-fore:

-

Forwards welding advance in position PA

- PC-back:

-

Backwards welding advance in position PC

- PC-fore:

-

Forwards welding advance in position PC

- PE-back:

-

Backwards welding advance in position PE

- PE-fore:

-

Forwards welding advance in position PE

References

Kim Y S, and Eagar T W, Weld J 72 (1993) 269.

Ley F H, Campbell S W, Galloway A M, and McPherson N A, Int J Adv Manuf Technol 80 (2015) 1213.

Brunov O, Solodskii S, and Zelenkovskii A, Weld Int 26 (2012) 710.

Rao Z H, Liao S M, and Tsai H L, J Appl Phys 107 (2010) 044902.

Romaní G, and Portolés A, Sold Tecnol Unión 19 (2008) 22.

Kang M, and Rhee S, Weld J 80 (2001) 1S.

Kang M, Kim Y, Ahn S, and Rhee S, Weld J 82 (2003) 238S.

Choi S, Yoo C, and Kim Y, Weld J 77 (1998) 38S.

Choi S, Yoo C, and Kim Y, Weld J 77 (1998) 38S.

Kah P, Salminen A, and Martikainen J, Mechanika 3 (2010) 68.

Dean G, Norrish J, and Cook C D, Aust Weld J 50 (2005) 34.

ISO/TC 44/SC7, Int Stand (2011) 24.

AWS Committee on Filler Metal, Ed., Specification for Carbon Steel Electrodes and Rods for Gas Shield Arc Welding Arc Welding. AWS A5.18/A5.18M, American Welding Society, Miami (2005), p 39.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Romaní, G., Meseguer-Valdenebro, J.L. & Portolés, A. Experimental Research on the Electrical Parameters of GMAW on Different Positions Welds. Trans Indian Inst Met 70, 159–166 (2017). https://doi.org/10.1007/s12666-016-0872-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0872-1