Abstract

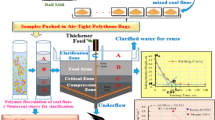

Full factorial design of experiment was employed to evaluate the effect of variables on the settling performance of coal fine. Influence of the variable parameters was discussed using 2D surface plots. Settling rate and turbidity were more sensitive to the flocculant dosage followed by the pH and the feed density. Highest settling rate of 190 mm/min was obtained with turbidity of supernatant liquid as 9 NTU at flocculant dosage of about 26 gpt and pH 9. Coefficient of correlation (R2) between the experimental and the predicted settling rate and the turbidity were found to be as 0.96 and 0.93 respectively.

Similar content being viewed by others

References

Cebeci Y, and Sönmez I, Fuel 85 (2006) 289.

Lemanowicz M, Jach Z, Kilian E, and Gierczycki E, Chem Eng J 168 (2011) 159.

Hassas B V, Karakaş F, and Çelik M S, Int J Miner Process 133 (2014) 97.

Parekh B K, Proced Earth Planet Sci 1 (2009) 621.

Dash M, Dwari R K, Biswal S K, Reddy P S R, Chattopadhyay P, and Mishra B K, Chem Eng J 173 (2011) 318.

Das B, Prakash S, Biswal S K, and Reddy P S R, J South Afr Inst Min Metall 106 (2006) 707.

Philip O, Nguyen A V, Bruce F, McNally C, and Ozdemir O, Chem Eng J 172 (2011) 914.

Rong R X, Hitchins J, Miner Eng 8 (1995) 293.

Pillai J, Nalco Company (1997).

Kanda H, and Makino H, Fuel 89 (2010) 2104.

Singh B P, Fuel 78 (1999) 501.

Ho Y C, Norli I, Abbas F M, and Morad N, Bioresour Technol 101 (2010) 1166.

Sabah E, and Cengiz I, Water Res 38 (2004) 1542.

Hogg R, Int J Miner Process 58 (2000) 223.

Parsapour G A, Hossininasab M, Yahyaei M, and Banisi S, Sep Purif Technol 122 (2014) 87.

Foshee W C, Swan M J, and Klimpel R R, Miner Eng (1982) 293.

Raichur A M, Misra M, Bukka K, and Smith R W, Coll Surf B Biointerf 8 (1996) 13.

Sabah E, and Erkan Z E, Fuel 85 (2006) 350.

Kumar S, Bhattacharya S, and Mandre N R, J South Afr Inst Min Metall 114 (2014) 945.

Shahabadi S M S, and Reyhani A, Sep Purif Technol 132 (2014) 50.

Lalit K, Reddy S M, Managuli R S, and Girish P K, Saud Pharm J (2015), article in press.

Golshani T, Jorjani E, Chehreh, C S, Shafaei, S Z, and Heidari, N Y, Int J Min Sci Technol 23 (2013) 261.

Njoya D, and Hajjaji M, J Asian Ceram Soc 3 (2015) 32.

Li M, Wood C J, and Davis J J, Int J Coal Prep Util 12 (1993) 117.

Aslan N, and Cebeci Y, Fuel 86 (2007) 90.

Sonmez I, Cebeci Y, and Senol D, Physicochem Probl Miner Process 50 (2014) 811.

Ucbeyiay H, Fuel Process Technol 106 (2013) 1–8.

Mandre N R, and Panigrahi D, Int J Miner Process 50 (1997) 177.

JMP Software http://www.jmp.com/support/help/Full_Factorial_Designs.shtml.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, S., Mandre, N.R. & Bhattacharya, S. Settling Study of Refuse Coal Fines: Performance Analysis Using Full Factorial Statistical Design Methodology. Trans Indian Inst Met 69, 1951–1957 (2016). https://doi.org/10.1007/s12666-016-0853-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0853-4