Abstract

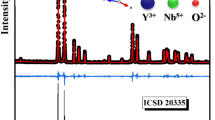

First time, bismuth titanate–calcium copper titanate (BTOX–CCTO1−X) composite materials were produced through sol–gel combustion process. X-ray diffraction analysis revealed that the obtained products were phase pure with dual phase composite system. Atomic percentage of each element present in the composite, observed by energy dispersive spectroscopy, was consistent with that in the raw materials as per stoichiometry. Field emission scanning electron microscopy showed evidence that the large CCTO grains embedded in small BTO grains and both co-existed with a bimodal distribution. The composite materials showed excellent dielectric behaviour that made them promising candidates for the high dielectric embedded capacitors. An efficient grey relational grade approach was introduced for improving the condition of major controlled parameters like frequency, operating temperature and molar composition and optimizing these parameters to obtain maximum dielectric constant and minimum dielectric loss simultaneously.

Similar content being viewed by others

References

Jiongxin L, and Wong C P, IEEE Trans Dielectr Elect Insul 15 (2008) 1322.

Min Y, Olmedo R, Hill M, Radhakrishnan K, Aygun K, Kabiri-Badr M, Panat R, Dattaguru S, and Balkan H, in Electronic Components and Technology Conference (2013) 1225.

Zhao N, Wan L, and Yu S, in Int. Conf. on Electronic Packaging Tech. and High density Packaging (2011) 264.

D. Chakravarty, P. Singh, S. Singh, D. Kumar, O. Parkash, J. Alloys Compd 438 (2007) 253.

Saboia K D A, Fechine P B A, Santos M R P, Freire F N A, Pereira F M M, and Sombra A S B, Polym Compo 28 (2007) 771.

Pinheiro A G, Pereira F M M, Santos M R P, Rocha H H B, and Sombra A S B, J Mater Sci 42 (2007) 2112.

Abdullah H, Jalal W N W, and Zulfakar M S, J Sol–Gel Sci Tech 69 (2014) 429.

Koparkar K A, Bajaj N S, and Omanwar S K, Defect Diffus Forum 361 (2015) 95.

Simoes A Z, Ries A, Filho F M, Riccardi R C, Varela J A, and Longo E, Appl Phys Lett 85 (2004) 5962.

Singh L, Rai U S, Mandal K D, Sin B C, Lee H, Chung H, and Lee Y, Mater Char 96 (2014) 54.

Raykar S J, D’Addona D M, and Mane A M, Procedia CIRP 7 (2013) 299.

Jayaraman P, and Mahesh Kumar L, Procedia Eng 97 (2014) 197.

Ravindran P, Manisekar K, Narayanasamy P, Selvakumar N, and Narayanasamy R, Mater Des 39 (2012) 42.

Magudeeswaran G, Nair S R, Sundar L, and Harikannan N, Def Tech 10 (2014) 251.

Deng J L, J Grey Syst 1 (1989) 1.

Joint Committee on Powder Diffraction Standards (JCPDS) database #: 73-2181.

Joint Committee on Powder Diffraction Standards (JCPDS) database #: 75-2188.

Kumar A, Nazzario R, Castro L T, Duarte A P, and Tomar M S, Int J Hydrogen Eng 40 (2015) 4931.

Pandey R, Meena B R, and Singh A K, J. Alloys Compd 593 (2014) 224.

Singh L, Kim I W, Sin B C, Ullah A, Woo S K, and Lee Y, Mater Sci Semicon Proces 31 (2015) 386.

Abdullah H, Jalal W N W, Zulfakar M S, Islam M T, Bais B, and Shaari S, J Kor Phys Soc 66 (2015) 41.

Tunc T, Dokme I, Altındal S, and Uslu I, J Appl Polym Sci 122 (2011) 265.

Sharma R, Pahuja P, Tandon R P, Pandey R, Meena B R, and Singh A K, J. Alloys compd 593 (2014) 224.

Shukla A, Choudhary R N P, Thakur A K, and Pradhan D K, Phys. B: Condens Mater 405 (2010) 99–106.

Rahaman M D, Setu S H, Saha S K, and Hossain A K M A, J. Magn Magn Mater 385 (2015) 418.

Koops C G. Phys Rev 83 (1951) 121.

Li J, Cho K, Wu N, and Ignatiev A, IEEE Trans Dielectr Electr Insul 11 (2004) 534.

Singh J P, Gautam S, Kumar P, Tripathi A, Chen J M, Chae K H, and Asokan K, J Alloys Comp 572 (2013) 84.

Dubey A K, Singh P, Singh S, Kumar D, and Parkash O, J Alloys Compd 509 (2011) 3899.

Gavartin J L, Ramo D M, Shluger A L, Bersuker G, and Lee B H, Appl Phys Lett 89 (2006) 1.

Rahman M T, Vargas M, and Ramana C V, J. Alloys Compd 617 (2014) 547.

Senn M S, Wright J P, and Attfield J P, Nature 481 (2012) 173.

Mishra P, and Kumar P, J. Alloys Compd 617 (2014) 899.

Ayesh A S, and Abdel-Rahem R, Bull Mater Sci 33 (2010) 589.

Hilczer B, Kulek J, Markiewicz E, Kosec M, and Mali B, J Non-Cryst Solid 305 (2002)167.

Li P, Mcdonald J F, and Lu T M, J Appl Phys 71 (1992) 5596.

Arbatti M, Shan X, and Cheng Z Y, Adv Mater 19 (2007) 1369.

Arun Kumar D, Selvasekarapandian S, Nithya H, Sakunthala A, and Hema M, Phys. B: Condens Mater 405 (2010) 3803.

Singh L, Kim I W, Sin B C, Mandal K D, Rai U S, Ullah A, Chung H, and Lee Y, RSC Adv 4 (2014) 52770.

Lin Y, Feng D Y, Gao M, Ji YD, Jin L B, Yao G, Liao FY, Zhang Y, and Chen C L, J Mater Chem C 3 (2015) 3438.

Acknowledgments

The authors acknowledge the Directorate of Extramural Research & Intellectual Property Rights (ER & IPR), Defence Research & Development Organization (DRDO), New Delhi, for providing financial support for this study (Project No. ERIP/ER/1104613/M/01/1460). The authors also thank Thiru A. Tenzing and Dr. S. Arivazhagan, Correspondent and Principal, respectively, of Mepco Schlenk Engineering College, Sivakasi, for their constant support and encouragement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandirengan, T., Arumugam, M., Durairaj, M. et al. Phase Investigation and Multi Objective Optimization of Dielectric Behaviour of Bismuth Titanate–Calcium Copper Titanate Nanocomposites Using Grey Relational Grade Analysis. Trans Indian Inst Met 69, 1819–1832 (2016). https://doi.org/10.1007/s12666-016-0845-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0845-4