Abstract

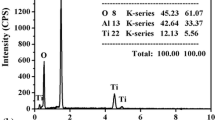

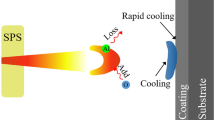

Powders of AlSi, 2024Al and 6061Al were separately ball milled with 15 wt% SiC reinforcement in a high-energy attrition ball mill using stainless steel balls for 8 h. The ball milled powders were plasma sprayed on the weathering steel (Cor-Ten) substrates to get Al–SiC composite coating with as much high volume fraction as possible of SiC. The microstructure characteristics of coatings were examined by SEM, XRD and image analyzer. XRD studies showed SiCp embedment in the Al matrix after ball milling, and nano grains in the ball milled powder and coatings. The thickness of coating and hardness were measured. The high adhesion-strength of the coatings observed might be attributed to higher degree of diffusion at the interface. The wear behaviors of the coatings were carried out under pin-on-disc wear test machine for 50 N load. Results showed that hardness and wear resistance of coatings depended on SiCp fraction and crystallite size in the matrix. The results of mechanical and wear tests also indicated that high-energy attrition ball milling and addition of SiC particles increased the strength, hardness and wear resistance of the coatings.

Similar content being viewed by others

References

Onoro J, Salvador M D, and L E G Cambronero, Mater Sci Eng A 499 (2009) 421.

Mula, S, Padhi P, Panigrahi S C, Pabi S K, and Ghosh S, Mater Res Bull 44 (2009) 1154.

Tailor S, PhD thesis, Malaviya National Institute of Tech., Jaipur, India (2013), p 27.

Mohanty R, Balasubramanian K, and Seshadri S, Mater Sci Eng A 498 (2008) 42.

Tailor S, Mohanty R M, Sharma V K, Soni P R, and Doub A V, Surf Eng (online first published), Maney Publication (2014). doi:10.1179/1743294414Y.0000000391

Dutkiewicz J, Litynska L, Maziarz W, Haberko K, Pyda W, and Kanciruk A, Cryst Res Technol 44 (2005) 1163.

Torralba J M, Costa C E, and Velasco F, J Mater Process Technol 133 (2003) 203.

Torres B H, Ibanez L, and Garcia-Escorial J A, Scripta Mater 47 (2002) 45.

Sahin Y, and Murphy S, J Mater Sci 34 (1996) 5399.

Hookery J A, and Doorbar P J, Mater Sci Technol 16 (2000) 725.

Froes F H, Mater Sci Eng A 184 (1994) 119.

Alizadeh M, and Mirzaei Aliabadi M, J Alloys Compd 509 (2011) 4978.

Ortiz J L, Amigo V, Manzano A, and Perez M A, Metall Mater Trans B 38 (2007) 1.

Yao B, Simkin B, Majumdar B, Smith C, Bergh M, Cho K, and Shon Y H, Mater Sci Eng A 536 (2012) 103.

Tailor S, Mohanty R M, Sharma V K, and Soni P R, J Therm Spray Technol 23 (2014) 1081.

Baghchesara M A, and Abdizadeh H, J Mech Sci Technol 26 (2012) 367.

Corrochano J, Lieblich M, and Ibanez J, Compos A 42, (2011) 1093.

Jia D C, Mater Sci Eng A 289 (2000) 83.

Tailor S, Sharma V K, Mohanty R M, and Soni P R, Trans Powder Metall Assoc India 38 (2012) 113

Tailor S, Sharma V K, Mohanty R M, and Soni P R, J Surf Eng Mater Adv Tech 2 (2012) 227.

Yamasaki T, Zheng Y J, Ogino Y, Terasawa M, Mitamura T, and Fukami T, Mater Sci Eng A 350 (2013) 168.

Moon K I, and Lee K S, J Alloys Compd 291 (1999) 312.

Mussert K M, Vellinga W P, Bakker A, and Van Der Zwaag S, Mater Sci 37 (2002) 789.

Ying D Y, and Zhang D L, Mater Sci Eng A 286 (2000) 152.

Zhao N, Nash P, and Yang X, J Mater Process Technol 170 (2005) 586.

Ye J, Han B Q, Lee Z, Ahn B, Nutt S R, and Schoenung J M, Scripta Mater 53 (2005) 481.

Tailor S, Sharma V K, Mohanty R M, and Soni P R, in Proceedings of EURO PM 2011 International Powder Metallurgy Congress & Exhibition, 9th–12th October 2011, Barcelona, Spain, EPMA, 2 (2011), p 91.

Sidhu T S, Prakash S, and Agarwal R D, J Mater Eng Perform 15 (2006) 122.

Modi O P, Prasad B K, Vegneswaran A H, and Vaidya M L, Mater Sci Eng A 151 (1992) 235.

Corrochano J, Walker J C, Lieblich M, Ibnez J, and Rainforth W M, Wear 270 (2010) 658.

Han Z, Lu L, and Lu K, Tribol Lett 21 (2006) 47.

Wang L, and Li D Y, Surf Coat Technol 167 (2003) 188.

Mishra R, Basu B, Balasubramaniam R, Mater Sci Eng A 373 (2004) 370.

El-Raghy T, Wear 238 (2000) 125.

Wang Z B, Mater Sci Eng A 352 (2003) 144.

Jafari M, Enayati M H, Abbasi M H, and Karimzadeh F, Mater Des 31 (2010) 663.

Wang S G, Liu Y, Long K, Lia S, and Zhang Z D, Wear 264 (2008)535.

Ozdemir I, Hamanaka I, Hirose M, Tsunekawa Y, and Okumiya M, Surf Coat Technol 200 (2005) 1155.

Tekmen C, Yamazaki M, Tsunekawa Y, and Okumiya M, Surf Coat Technol 202 (2008) 4163.

Tekmen C, Tsunekawa Y, and Okumiya M, Surf Coat Technol 202 (2008) 4170.

Saha P K, Aluminum Extrusion Technology, ASM International, Materials Park (2000).

Williamson G K, and Hall W H, Acta Metall 1 (1953) 22.

Araujo P, Chicot D, Staia M, and Lesage J, Surf Eng 21 (2005) 35.

Soni P R, Mechanical Alloying-Fundamentals & Applications, Cambridge International Science Publishing, Cambridge (2001).

Tailor S, Mohanty R M, and Soni P R, J Mater Sci Surf Eng 1 (2013) 15.

Van Steenkiste T H, Elmoursi A, Gorkiewicz D, and Gillispie B, Surf Coat Technol 194 (2005) 103.

Shorowordi K M, Laoui T, Haseeb A S M A, Celis J P, and Froyen L, J Mater Process Technol 142 (2003) 738–743.

Saravanan R A, Lee J M, and Kang S B, Metall Mater Trans A 30A (1999) 2523.

Zhang Z F, Zhang L C, and Mai Y W, J Mater Sci 30 (1995) 5999.

Ludema K C, Wear 100 (1984) 315.

Williams J A, Dyson I N, and Kapoor A, J Mater Res 14 (1999) 1548.

Williams J A, Tribol Int 38 (2005) 863.

Acknowledgments

The authors gratefully acknowledge the financial support of the Ministry of Education and Science of the Russian Federation in the framework of Increase Competitiveness Program of NUST «MISiS» (Grant № К4-2014-081) and financial & experimental support of Malaviya National Institute of Technology Jaipur, India and Council of Scientific and Industrial Research, CSIR-HQS, Rafi Marg, New Delhi-110001, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tailor, S., Mohanty, R.M., Soni, P.R. et al. Wear Behavior of Plasma Sprayed Nanostructured Al–SiCp Composite Coatings: A Comparative Study. Trans Indian Inst Met 69, 1179–1191 (2016). https://doi.org/10.1007/s12666-015-0692-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0692-8