Abstract

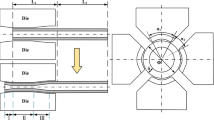

Tube drawing process is comprised of many factors that have great impact on the formed part quality and die life. In producing polygonal sections from round tube, due to accumulation of residual stress in corners, the final shape of the drawn part is to some extent different from what is expected. Therefore, selection of optimal combination of drawing parameters for enhancing the parts quality and die life is crucial. In the present paper, a complete multi criteria optimization procedure starting from numerical modeling, and leading to the search of robust optimal process parameters is proposed. A numerical model of tube drawing process of aluminum alloy for rectangular section is developed by means of ABAQUS and validated experimentally. Then a total set of 27 numerical tests are conducted based on four-factors and three levels Box–Behnken design to correlate empirical relationship between factors (i.e., die angle, bearing length, friction coefficient and drawing velocity) and responses (i.e., drawing force, linear and peripheral thickness distributions and dimensional error). Response surface model of each quality characteristic is obtained and analysis of variances is performed to check the adequacy of developed models. Finally the obtained RSM models are integrated with their weight factors and the objective function is formed. This function is then associated with artificial bee colony (ABC) algorithm to find factor combination regarding minimum drawing force and dimensional error, as well as maximum thickness distributions. Results indicate that the optimal result obtained through RSM–ABC is in agreement with those derived from simulations and confirmatory experiments.

Similar content being viewed by others

References

Bayoumi L S, Attia A S, J Mater Process Technol 209 (2009) 1835

Bayoumi L S, Int J Mech Sci 43 (2001) 241

Hwang Y M, Altan Y, Finite Element Anal Des 39 (2002) 1071

Manabe K, Amino M, J Mater Process Technol 123 (2002) 285

Kridli G T, Bao L, Malliek P K, Tian Y, J Mater Process Technol 133 (2003) 287

Leu D K, Wu J Y, Int J Adv Manuf Technol 25 (2005) 691

Hwang Y M, Chen W C, Int J Plast 21 (2005) 1815

Ghasemi-Baboly M, Aminian M, Leseman Z, Teimouri R, Soft Comput (2014), doi:10.1007/S00500-014-1305-x

Shahi AS, Pandey S, J Mater Proc Technol 196 (2008) 339

Akay B, Karaboga D, J Intell Manuf 23 (2012) 1001, doi:10.1007/s10845-010-0393-4

Basturk B, Karaboga D, An artificial bee colony (ABC) algorithm for numeric function optimization. in Proc IEEE Swarm Intell Symp, Indianapolis, IN, USA (2005)

Teimouri R, Baseri H, Prod Eng Res Devel 6 (2012) 493

Teimouri R, Baseri H, J Intell Manuf (2013), doi:10.1007/s10845-013-0784-4

Box G E P, Draper N R, Empirical Model-Building and Response Surfaces, Wiley, New York (1986)

Mayers R H, Montgomery D C, Response Surface Methodology, Wiley, New York (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salehi, M., Hosseinzadeh, M. & Elyasi, M. A Study on Optimal Design of Process Parameters in Tube Drawing Process of Rectangular Parts by Combining Box–Behnken Design of Experiment, Response Surface Methodology and Artificial Bee Colony Algorithm. Trans Indian Inst Met 69, 1223–1235 (2016). https://doi.org/10.1007/s12666-015-0670-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0670-1