Abstract

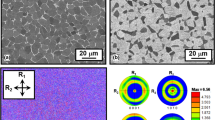

Flow behavior of Ti-6Al-4V was investigated under multi directional isothermal compressions. Flow curves of multi directional isothermal compressions were analyzed to determine softening parameter, which is the ratio of maximum flow stress (σi) to steady state flow stress (σs). Multi directional isothermal compressions were carried out at a optimum strain-rate of 10−2 s−1. Softening parameter increased gradually from first to third stage of compression. The huge strain imposed on the specimen reduced grain size from 16 µm to approximately 7–8 µm, which is suitable for superplastic deformation and also improved strength.

Similar content being viewed by others

References

Barnes J, J Mater Eng Perform 16 (2007) 440.

Serra D, A Review of ITP Manufacturing Processes 6th EUROSPF Conference EuroSPF08, 3–5 September 2008, Carcassonne, France, p 1.

Davis B, and Hryn J. Report, Innovative Forming and Fabrication Technologies: New Opportunities, Argonne National Laboratory, U.S. Department of Energy laboratory, 31 January 2008, Assessed online at http://www.osti.gov/bridge/product.biblio.jsp?osti_id=924692, p 9.

Hamilton CH, and Paton N, in Proceedings of the International conference on the Minerals, Metals and Materials Society, USA (1988), p 706.

ARGARD-LS-154, Superplasticity, Advisory Group for Aerospace Research and Development, NATO (1987), p 204.

Katou M, Oh J, Miyamoto Y, Matsuura K, and Kudoh M, Mater des 28 (2007) 2093.

Moiseyev VN, Titanium alloys: Russian aircraft and aerospace applications, CRC Press Taylor & Francis group, Boca Raton, vol 6 (2006), p 169.

Buafeld B, Van Der Biest O, and Gault R, J Mater Res 100 (2009) 1536.

Buafeld B, and Van Der Biest O, Sci Technol Adv Mater 10 (2009) 1.

Zhang XZ, Cai QZ, Zhou GF, Chen QF, and Xiong YZ, J Mater Sci 46 (2011) 1789.

Valiev Z, Islamgaliev RK, and Alexandrov IV, J Mater Sci 45 (2000) 130.

Mishra RS, Stolyarov VV, Echer C, Valiev RZ, and Mukherjee AK, Mater Sci Eng A 298 (2001) 44.

Sergueeva AV, Stolyarov VV, Valiev RZ, and Mukherjee AK, Scr Mater 43 (2000) 819.

Salishchev GA, Galeyev RM, Valiakhmetov OR, Safiullin RV, Lutfullin RY, Senkov ON, Froes FH, and Kaibyshev OA, J Mater Proc Technol 116 (2001) 265.

Segal VM, J Mater Sci Eng A A271 (1999) 322.

Ko, YG, Lee CH, Shin DH, and Semiatin SH, Metall Mater Trans A 37 (2006) 381.

Liu J, Tan M-J, Aue-u-lan Y, Guo M, Castagne S, and Chua B-W, Int J Adv Manuf Technol 69 (2013) 1097.

Babu J, Dutta A, and Kumaraswamy A, Proc Mater Sci 6 (2014) 1121.

Luo J, and Li M, Rare Metals, 30 (2011) 555.

Sitdikov O, Sakai T, Goloborodko A, Kaibyshev R, and Miura H, Mater Trans 45 (2004) 2232.

Acknowledgments

The authors are grateful to the Director, DMRL Hyderabad for granting permission to use the facilities for conducting experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Babu, J., Dutta, A. & Kumaraswamy, A. Flow Behaviour of Ti-6Al-4V Subjected to Multi Directional Isothermal Compression. Trans Indian Inst Met 68 (Suppl 1), 105–108 (2015). https://doi.org/10.1007/s12666-015-0630-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0630-9