Abstract

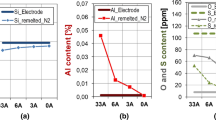

Slag properties affect the efficiency of Electro Slag Remelting (ESR) process by removing the quality impairing elements (S, P, etc.), while avoiding valuable alloying element losses. Therefore, a relation between element losses and optical basicity of slags, which may be assumed to be an enhanced approach to basicity concept, would play a crucial role on predicting and selecting the optimum slag composition for ESR process. The primary contribution of this paper is to investigate the effect of optical basicity of various slags on the composition change of high sulphur containing AISI 12L14 (DIN11SMnPb37) free-cutting and AISI M2 (DIN HS6-5-2C) high speed steels. For this purpose steel bars were remelted under different slag compositions at constant melting conditions. According to the chemical analysis of the products, it was observed that the element losses increase related to increasing optical basicity of slags. On the other hand, these alloying element changes show variety on steel types. High speed steel shows a relatively low alloying element changes due to its high carbide content, while higher losses were discovered in free cutting steels.

Similar content being viewed by others

References

Mattar T M T, Fathy A M and Eissa M M, in Proc Symp METAL 2001, Tanger, Ostrava (2001) p 1.

Mehrabi K, Rahimipour M and Shokuhfar A, Int J Iron Steel Soc Iran 2 (2005) 37.

Vaish A, Iyer G and De P, J Metall Mater Sci 42 (2000) 11.

Eissa M and El-Mohammadi A, Steel Res 69 (1998) 413.

Hayashi M, Sano N and Fredriksson P, ISIJ Int 44 (2004) 1783.

Ban-Ya S, Hobo M, Kaji T, Itoh T and Hino M, ISIJ Int 44 (2004) 1810.

Sosinsky D J and Sommerville I D, Metall Trans B 17 (1986) 331.

Young R, Duffy J, Hassall G and Xu Z, Ironmak Steelmak 19 (1992) 201.

Shankar A, Görnerup M, Seetharaman S and Lahiri A K, Metall Mater Trans B 37 (2006) 941.

Taniguchi Y, Wang L, Sano N and Seetharaman S, Metall Mater Trans B 43 (2012) 477.

Simeonov S R, Ivanchev I N and Hainadjiev A V, ISIJ Int 31 (1991) 1396.

Mohassab-Ahmed M Y, Sohn H Y, and Kim H G, Ind Eng Chem Res 51 (2012) 3639.

Gao Y, Liu Q and Bian L, Metall Mater Trans B 43 (2011) 229.

Duffy J A and Ingram M D, J Inorg Nucl Chem 37 (1975) 1203.

Park G-H, Kang Y-B and Park J H, ISIJ Int 51 (2011) 1375.

Kalicka Z, Kawecka-Cebula E and Pytel K, Arch Metall Mater 54 (2009) 179.

Yang Y, Mckague A, Sommerville I and Mclean A, Can Metall Q 36 (1997) 347.

Nasu M, Mills K C, Monaghan B J, Jakobsson A and Seetharaman S, Ironmak Steelmak 26 (1999) 353.

Kawai Y, Nakao R and Mori K, Trans Iron Steel Inst Japan 24 (1984) 509.

Yin-Dong Y and Edström J O, Scand J Metall 21 (1992) 202.

Fellner P and Krohn C, Can Metall Q 8 (1969) 275.

Liu X, Wijk O, Selin R and Edström O J, ISIJ Int 38 (1998) 36.

Wei C H, Spec Melting Process Technol 05 (1989) 235.

Ahmed A and Fathy A, Ironmak Steelmak 35 (2008) 458.

Mattar T, in Proc Symp 6th International Tooling Conference (TOOL), (eds) Bergström J, Karlstad Univ, Karlstad (2002), p 403.

Mattar T, El-Faramawy H, and Fathy A, in Proc Symp 6th International Tooling Conference (TOOL), (eds) Bergström J, Karlstad Univ, Karlstad (2002), p 411.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Birol, B., Saridede, M.N. The Effect of Slag Optical Basicity on Alloying Element Losses of Steel by Electroslag Remelting (ESR). Trans Indian Inst Met 69, 751–757 (2016). https://doi.org/10.1007/s12666-015-0549-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0549-1