Abstract

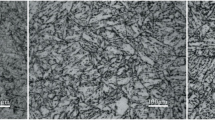

Microstructure and mechanical properties of P92 steel in the normalized and tempered, and thermal aged at 923 K for 5,000 h conditions have been investigated. Laves phase (size of ~0.160 µm) was observed in the thermal aged steel. Tensile tests were carried out at a strain rate of 3 × 10−4 s−1 and in the temperature range of 300–923 K. Both in the normalized and tempered, and thermal aged conditions, yield stress and ultimate tensile strength of the steels were found to decrease with increase in test temperatures. Tensile strengths of the thermal aged steel were decreased significantly in all test temperatures in comparison with normalized and tempered condition. Tensile strengths of thermal aged steel decreased due to sub-structure recovery and loss of solid solution strengthening from tungsten. Creep tests were conducted at 923 K in the stress range of 130–110 MPa. Lower creep rupture life has been observed in the thermal aged steel than normalized and tempered steel at higher stress level. Creep rupture life of thermal aged steel was comparable with steel in the normalized and tempered condition at lower stress levels. The presence of Laves phase precipitates in thermal aged steel has compensated the creep strength decrement due to loss of tungsten and sub-structure recovery in the steel.

Similar content being viewed by others

References

Laha K, Chandravathi K S, Parameswaran P, Bhanu Sankara Rao K, and Mannan S L, Metal Mater Trans A 38A (2007) 58.

Ennis P J, Zielinska-Lipiec A, Wachter O, and Czyrska-Filemonowicz A, Acta Mater 45 (1997) 4901.

Maruyama K, Sawada K, and Koike J, Iron Steel Inst Japan Int 41 (2001) 641.

yrostkov´a A V´, Homolov´a V, Pecha J, and Svoboda M, Mater Sci Eng A 480 (2008) 289.

Dudko V, Belyakov A, Molodov D, and Kaibyshev R, Metal Mater Trans A 44A (2013) S162.

Fedorova I, Kipelova A, Belyakov A, and Kaibyshev R, Metal Mater Trans A 44A (2013) S128.

Abe F, Mater Sci Eng A319–321 (2001) 770.

Sawada K, Kubo K, and Abe F, Mater Sci Eng A319–321 (2001) 784.

Pe´try C, and Lindet G, Int J Press Vessels Pip 86 (2009) 486.

Korcakova L, Hald J, and Somers M A J, Mater Charact 47 (2001) 111.

Lee J S, Armaki H G, Maruyama K, Muraki T, and Asahi H, Mater Sci Eng A 428 (2006) 270.

Masuyama F, Int J Press Vessels Pip 87 (2010) 617.

Sawada K, Hongo H, Watanabe T, and Tabuchi M, Mater Charact 61 (2010) 1097.

Klueh R L, Int Mater Rev 50 (2005) 287.

Naoi H, Ohgami M, Araki S, Ogawa T, Yasuda H, Masumoto H, and Fujita T, Development of High-Strength Ferritic Steel NF616 for Boiler Tubes, Nippon Steel Technical Report, No. 50 (1991), p 7.

Ohgami M, Mimura H, Naoi H, Ikemoto T, Kinbara S, and Fujita T, Nippon Steel Technical Report, No.72 (1997), p 59.

Kim B, and Lim B, Int J Mod Phys B 20 (2006) 4231.

Sakthivel T, Vasudevan M, Laha K, Parameswaran P, Chandravathi K S, Panneer Selvi S, Maduraimuthu V, and Mathew M D, Mater Sci Eng A 591 (2014) 111.

Guo X, Gong J, Jiang Y, and Rong D, Mater Sci Eng A 564 (2013) 199.

Abe F, Sci Technol Adv Mater 9 (2008) 013002.

Rodriguez P, Bull Mater Sci 6 (1984) 653.

Frost H J, and Ashby M F, Deformation-Mechanism Maps-the Plasticity and Creep of Metals and Ceramics, 1st ed., Pergamon Press, New York (1982), p 62.

Mukherjee A K, Bird J E, and Dorn J E, ASTM Trans Quart 52 (1969) 155.

Lagneborg R, and Bergman B, Metal Sci J 10 (1976) 20.

Acknowledgments

The authors wish to thank Dr. P.R. Vasudeva Rao, Director, Indira Gandhi Centre for Atomic Research, Dr. T. Jayakumar, Director, Metallurgy and Materials Group and Dr. A.K. Bhaduri, Associate Director, Materials Development and Technology Group, for their keen interest in the work and encouragement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sakthivel, T., Laha, K., Parameswaran, P. et al. Effect of Thermal Aging on Microstructure and Mechanical Properties of P92 Steel. Trans Indian Inst Met 68, 411–421 (2015). https://doi.org/10.1007/s12666-014-0480-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-014-0480-x