Abstract

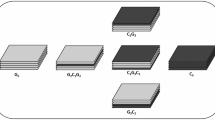

A thermosetting epoxy resin was hybrid modified by addition of 9 wt% of rubber micro-particles and 10 wt% of silica nanoparticles. Glass fiber reinforced plastic (GFRP) composite laminates employing the unmodified (GFRP-neat) and the hybrid modified (GFRP-hybrid) epoxy matrix was fabricated. Mechanical properties viz., tension, compression, Interlaminar shear strength, and flexure, were determined for these GFRP composites in both room temperature (RT) and in hot-wet (HW) conditions. All the mechanical tests were conducted following their respective ASTM test standard specifications. Prior to testing, HW specimens were hygrothermally aged until moisture absorption saturation was attained. The GFRP-hybrid composite absorbs moisture at a higher rate and saturates with higher moisture content than that by GFRP-neat composite. The hybrid modification of epoxy matrix of GFRP composite alters the mechanical properties in RT by about +6 to −12 % and in HW conditions by about +3 to −9 %, depending on the specific property. The degradation of mechanical properties due to moisture varies from about 0 to 23 % in both GFRP composites. Dramatic improvement of over 160 % in fracture toughness and over 400 % in fatigue life of GFRP-hybrid composite reported earlier, appear to more than compensate for minor alterations in other mechanical properties of this material.

Similar content being viewed by others

References

Thostenson ET, Li C and Chou TW, Comp Sci Tech 65 (2005) 491.

Hussain F, Hojjati M, Okamoto M and Gorga RE, J Comp Mater 40 (2006) 1511.

Ma J, Mo MS, Du XS, Rosso P, Friedrich K and Kuan HC, Polymer 49 (2008) 3510.

Yazhou Guo and Yulong Li, Mater Sci Eng A458 (2007) 330.

Chisholm N, Mahfuz H, Rangari VK, Ashfaq A, and Jeelani S, Compos Struct 67 (2005) 115.

Su Zhao, Linda, S. Schadler, Henrik Hillborg and Tommaso Auletta, Compos Sci Tech 68 (2008) 2976.

Wetzel B, Rosso P, Haupert F and Friedrich K, Eng Fract Mech 73 (2006) 2375.

Gojny FH, Wichmann MHG, Fiedler B, Bauhofer W and Schulte K, Compos A Appl Sci Manufac 36 (2005) 1525.

Spitalsky Z, Tasis D, Papagelis K and Galiotis C, Prog Polym Sci 35 (2010) 357.

Zhou Y, Pervin F, Jeelani S and Mallick PK, J Mater Proc Tech 198 (2008) 445.

Zhou Y, Rangari V, Mahfuz H, Jeelani S and Mallick PK, Mater Sci Engg A402 (2005) 109.

Khan SU, Munir A, Hussain R and Kim JK, Compos Sci Tech 70 (2010) 2077.

Zhou Y, Hosur M, Jeelani S and Mallick P, J Mater Sci 47 (2012) 5002.

Cho J, Chen JY and Daniel IM, Scr Mater 56 (2007) 685.

Rafiee MA, Yavari F, Rafiee J and Koratkar N, J Nano Part Res 13 (2011) 733.

Adachi T, Osaki M, Araki W and Kwon SC, Acta Mater 56 (2008) 2101.

Wang G-T, Liu H-Y, Saintier N and Mai Y-W, Eng Fail Analy 16 (2009) 2635.

Liang YL and Pearson RA, Polymer 51 (2010) 4880.

Kinloch AJ, Mohammed RD,Taylor AC, Eger C, Sprenger S and Egan D, J Mater Sci 40 (2005) 5083.

Kinloch AJ, Mohammed RD,Taylor AC, Sprenger S and Egan DJ, J Mater Sci 41 (2006) 5043.

Kinloch AJ, Masania K, Taylor AC, Sprenger S and Egan D, J Mater Sci 43 (2008) 1151.

Manjunatha CM, Sprenger S, Taylor AC and Kinloch AJ, J Compos Mater 44 (2010) 2095.

Böger L, Sumfleth J, Hedemann H and Schulte K, Compos A Appl Sci Manufact 41 (2010) 1419.

Li J, Wong PS and Kim JK, Mater Sci Eng A 483 (2008) 660.

Manjunatha CM, Ramesh Bojja, Jagannathan N, Kinloch AJ and Taylor AC, Int J Fat 54 (2013) 25.

G.S Springer, “Environmental effects on composite materials”, (ed), Springer GS, Lancaster, PA: Technomic Publishing company Inc., vol. 3, pp 1–34.

Sharma B, Mahajan S, Chhibber R and Mehta R. Procedia Chemistry 2012. doi:10.1016/j.proche.2012.06.006.

Alamri H and Low IM. Mater Des 42:(2012) 214.

Alamri H and Low IM, Compos A Appl Sci Manufact 44 (2013) 23.

Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials, ASTM D5229 M, Annual book of ASTM Standards, American Society for Testing and Materials, PA, Vol. 15.03, (2003).

Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials, ASTM D3039, Annual book of ASTM Standards, American Society for Testing and Materials, PA, Vol. 15.03, (2003).

Standard Test Method for Compression Properties of Polymer Matrix Composite Materials, ASTM D3410, Annual book of ASTM Standards, American Society for Testing and Materials, PA, Vol. 15.03, (2003).

Standard Test Method for Ilss Polymer Matrix Composite Materials, ASTM D2344, Annual book of ASTM Standards, American Society for Testing and Materials, PA, Vol. 15.03, (2003).

Standard Test Method for Flexure Properties of Polymer Matrix Composite Materials, ASTM D790, Annual book of ASTM Standards, American Society for Testing and Materials, PA, Vol. 15.03, (2003).

Uddin MF and. Sun CT, Compos Sci Tech 68 (2008) 1637.

Manjunatha CM, Taylor AC, Kinloch AJ and Sprenger S, Compos Sci Tech 70 (2010) 193.

Shao-Yun Fu, Xi-Qiao Feng, Bernd Lauke and Yiu-Wing Mai, Compos B: Eng 39 (2008) 933.

Dadfar MR and Ghadami F, Mater Des 47 (2013) 16.

Garima Tripathi and Deepak Srivastava, Mater Sci Eng A 443 (2007) 262.

Manjunatha CM, Taylor AC, Kinloch AJ and Sprenger S, J Reinf Plast Compos 29 (2010) 2170.

Rao RMVGK, Balasubramanian N and Chanda M, J Reinf Plast Compos 3 (1984) 232.

Shylaja S and Rao RMVGK, J Reinf Plast Compos 18 (1999) 921.

Cunha JAP, Costa ML and Rezende MC, Latin Am J Solids Struct 5 (2008) 157.

Iain McEwana, Pethricka RA and Stephen JS, Polymer 40 (1999) 4213.

Chen Zou, Fothergillm JC, Rowe SW, IEEE Trans Dielect Electr Insul 15 (2008) 106.

Santhosh M, Deepika R, Revathi A, Prakash MR, Shylaja S and Rao RMVGK, J Reinf Plast Compos 23 (2004) 1883.

Shen, CH and Springer GS, J Compos Mater 10 (1976) 2.

B.DeNève, Shanahan MER, Polymer 34 (1993) 5099.

Acknowledgments

Authors wish to thank Mr. Shyam Chetty, Director, Dr. G.N. Dayananda, Head, CSMST and Dr. Satish Chandra, Head, STTD, NAL, Bangalore for their support and encouragement during this work. Part of this work was carried out in the Department of Mechanical Engineering, Imperial College, London, UK. The support from Prof. AJ Kinloch and Dr. AC Taylor are acknowledged with thanks. The authors would also like to thank all the technical support staff members of the Dept. of Mech. Engg. and the Composite Centre of Dept. of Aeronautics, Imperial College London, staff members, STTD and CSMST, CSIR-NAL, Bangalore for their assistance in the experimental studies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jagannathan, N., Bojja, R., Revathi, A. et al. Mechanical Properties of a Hybrid Nanocomposite Under Room Temperature and Hot-Wet Environments. Trans Indian Inst Met 68, 363–369 (2015). https://doi.org/10.1007/s12666-014-0463-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-014-0463-y