Abstract

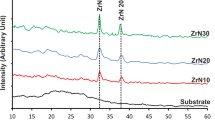

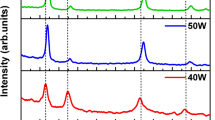

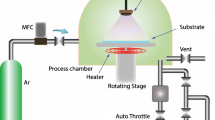

Thin films of ZrAl and ZrAlN were deposited on Si(100) substrates in the temperature range 300–773 K and with varying nitrogen flow rate from 0 to 10 sccm by co-sputtering of Zr (99.9 % purity) and Al (99.9 % purity) targets using a single pulsed power supply. At substrate temperature of 773 K, ZrAl thin films crystallized in hcp structure. The nitrogen flow rate was found to significantly influence the phase formation in ZrAlN films with the formation of fcc structure with a nitrogen flow rates in the range 1–2 sccm. The electrical resistivity of ZrAl films decreased from 62 to 24 μΩ cm with increase of substrate temperature, while it increased with nitrogen flow rate as a consequence of change in crystal structure and decrease in the crystallite size. Nanohardness measurements indicated a maximum hardness and elastic modulus of 20 and 369 GPa, respectively for ZrAlN films deposited at 773 K and 1 sccm of nitrogen flow rate.

Similar content being viewed by others

References

Balaceanu M, Petreus T, Braic V, Zoita C N, Vladescu A, Cotrutz C E, and Braic M, Surf Coat Technol 204 (2010) 2046.

Hollis K J, International Thermal Spray and Surface Engineering, vol 5 (eds), Gansert R and Jarosinski W, Joe Zion, ASTM thermal spray society, Materials Park, Ohio (2010).

Pichon L, Girardeau T, Straboni A, Lignou F, and Guerin P, Appl Surf Sci 150 (1999) 115.

Jehn H A, Surf Coat Technol 131 (2000) 433.

Nose M, Zhou M, Honbo E, Yokota M, and Saji S, Surf Coat Technol 142 (2001) 211.

Mitterer C, Holler F, Reitberger D, Badisch E, Stoiber M, Lugmair C, Nöbauer R, Müller Th, and Kullmer R, Surf Coat Technol 163-164 (2003) 716.

Hörling A, Ultman H, Oden M, Sjölén J, and Karlsson L, J Vac Sci Technol A Vac Surf Films 20 (2002) 1815.

Lamni R, Sanjinés R, and Lévy F, Thin Solid Films 478 (2005) 170.

Rogström L, Johnson L J S, Johansson M P, Ahlgren M, Hultmanband L, and Odén M, Scripta Mater 62 (2010) 739.

Kanga Y B, Li D J, Wang H Y, Yan J Y, Zhang S, and Deng X Y, Appl Surf Sci 258 (2012) 2206.

Rogström L, Johnson L J S, Johansson M P, Ahlgren M, Hultman L, Odén M, Thin Solid Films 519 (2010) 694.

Sanjinés R, Sandu C S, Lamni R, and Lévy F, Surf Coat Technol 200 (2006) 6308.

Musil J, and Hruby H, Thin Solid Films 365 (2000) 104.

Klostermann H, Fietzke F, Modes T, and Zywitzki O, Rev adv Mater Sci 15 (2007) 33.

Singh A, Kumar N, Kuppusami P, Prasanthi T N, Chandramohan P, Dash S, Srinivasan M P, Mohandas E, and Tyagi A K, Wear 280–281 (2012) 22.

Acknowledgments

The authors are thankful to Smt. M. Jyothi for substrate preparation and XRD analysis.They are also grateful to Dr. M. Vijayalakshmi, AD, PMG, Dr. T. Jayakumar, Director, Metallurgy and Materials Group and Shri S. C. Chetal, Director, IGCAR for the support and encouragement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, A., Kuppusami, P., Thirumurugesan, R. et al. Characterisation of ZrAl and ZrAlN Thin Films Prepared by Pulsed DC Magnetron Sputtering. Trans Indian Inst Met 66, 363–367 (2013). https://doi.org/10.1007/s12666-013-0248-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-013-0248-8