Abstract

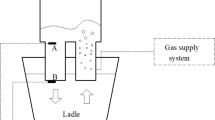

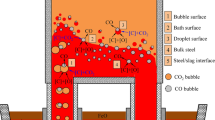

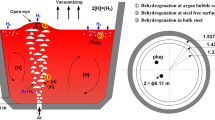

In recent times the demand of ultra-low carbon steel (ULCS) with improved mechanical properties such as good ductility and good workability has been increased as it is used to produce cold-rolled steel sheets for automobiles. For producing ULCS efficiently, it is necessary to improve the productivity of the vacuum degassers such as RH, DH and tank degasser. Recently, it has been claimed that using a new process, called REDA (revolutionary degassing activator), one can achieve the carbon content below 10 ppm in less time. As such, REDA process has not been studied thoroughly in terms of fluid flow and mass transfer which is a necessary precursor to understand and design this process. Therefore, momentum and mass transfer of the process has been studied by solving momentum and species balance equations along with k–ε turbulent model in two-dimension (2D) for REDA process. Similarly, computational fluid dynamic studies have been made in 2D for tank and RH degassers to compare them with REDA process. Computational results have been validated with published experimental and theoretical data. It is found that REDA process is the most efficient among all these processes in terms of mixing efficiency. Fluid flow phenomena have been studied in details for REDA process by varying gas flow rate, depth of immersed snorkel in the steel, diameter of the snorkel and change in vacuum pressure. It is found that design of snorkel affects the melt circulation in the bath significantly.

Similar content being viewed by others

References

Kitamura S, Miyamoto K, and Tsujino R, Tetsu to Hagane 80 (1994) 101.

Domgin J F, Gardin P, Saint-Raymond H, Stouvenot F, and Huin D, Steel Res Int 76 (2005) 5.

Kitamura S, Harashima K, Tsutsumi N, and Yano M, Tetsu to Hagane 80 (1994) 213.

Nobuhiro M, Felicia L, Hiroshi N, Gupta G S, and Shin-ya K, ISIJ Int 50 (2010) 89.

Kitamura S, Aoki H, Miyamoto K, Furuta H, Yamashita K, and Yonezawa K, ISIJ Int 40 (2000) 455.

Taniguchi S, Okada Y, Sakai A, and Kikuchi A, in Proc of 6th Int Iron & Steel Congress, ISIJ, Nagoya (1990), 394.

Guo D, and Irons G A, Metall Mater Trans B 31 (2000) 1447.

Mondal M, Gupta G S, Kitamura S, and Maruoka N, in Proc CHEMECA 2008, Perth, Sept 2008.

Mondal M, Maruoka N, Kitamura S, and Gupta G S, Arch Metall Mater 55 (2010) 1131.

Kitamura S, Aoki H, and Miyamoto K, 8th Japan–China Symp On Sci & Tech of Iron & Steel, (1998), p 110.

Aoki H, Kitamura S, and Miyamoto K, I & SM, (1999), 17.

Guo D, and Irons G A, Mater Trans B 31B (2000b) 1457.

Johansen S T, and Boysan F, Metall Mater Trans B 19B (1988) 755.

Joo S, and Guthrie R I L, Metall Trans B 23B (1992) 765.

Szekely J, and Asai S, Trans ISIJ 15 (1975) 270.

Mazumdar D, and Guthrie R I L, Metall Mater Trans B 16B (1985) 83.

Park Y, Doo W, Yi K, and An S, ISIJ Int 40 (2000) 749.

Park Y, and Yi K, ISIJ Int 43 (2003) 1403.

Launder B E, and Spalding D B, Comp Methods Appl Mech Eng 3 (1974) 269.

Shrirabe K, and Szekely J, Trans ISIJ 23 (1983), 465.

Johansen S T, Robertson D G C, Woje K, Engh T A, Metall Mater Trans B 19B (1988) 745.

Zhu M Y, Inomoto T, Sawada I, and Hsiao T C, ISIJ Int 35 (1995) 472.

Kuwabara T, Umezawa K, Mori K, and Watanabe H, Trans Iron Steel Inst Japan 28 (1988) 305.

Kurokawa N, in Proc of 5th Int Conf for Licenses of the RH Process, Thyssen Stahl Aktiengesellschaft, Duisburg, (1987) p 61.

Neifer M, Rodi S, and Sucker D, Steel Res 64 (1993) 54.

Acknowledgements

One of the authours (GSG) would like to thank Tohoku University (IMRAM, Sendai, Japan) for inviting him as Visiting Professor.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mondal, M.K., Maruoka, N., Kitamura, S. et al. Study of Fluid Flow and Mixing Behaviour of a Vacuum Degasser. Trans Indian Inst Met 65, 321–331 (2012). https://doi.org/10.1007/s12666-012-0136-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-012-0136-7