Abstract

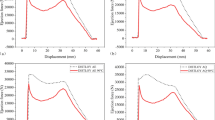

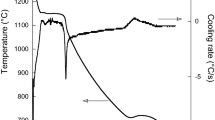

In ferrous powder metallurgy, copper and graphite are used as common alloying elements. Copper melts at low temperature compared to iron and forms liquid which promote interparticle bond formation. However, it also results in compact swelling. To negate this, graphite is used as an additive. This study examines the influence of copper and graphite addition on the densification, dimensional changes, and mechanical properties of iron compacts sintered at 1120°C. These properties have been correlated with the microstructure.

Similar content being viewed by others

References

Berner D, Exner H and Petzow G, Swelling of Iron-Copper Mixtures during Sintering and Infiltration, Modern Developments in Powder Metallurgy, 6 (1973) 237.

Kaysser W, Huppmann W and Petzow G, Analysis of Dimensional Changes during Sintering of Fe-Cu, Powder Metallurgy, 23 (1980) 86.

Tabeshfar K and Chadwick G A, Dimensional Changes during Liquid Phase Sintering of Fe-Cu Compacts, Powder Metallurgy, 27 (1984) 19.

Jamil S and Chadwick G, Investigation and Analysis of Fe-Cu and Fe-Cu-C Compacts, Powder Metallurgy, 28 (1985) 65.

Lawcock R and Davies T, Effect of Carbon on Dimensional and Microstructural Characteristics of Fe-Cu Compacts during Sintering, Powder Metallurgy, 33 (1990) 147.

Wanibe Y and Yokoyama H. Itoh T, Expansion during Liquid Phase Sintering of Iron-Copper Compacts, Powder Metallurgy, 33(1) (1990) 65.

Griffo A and German R M, Dimensional Control in the Sintering of Iron-Copper-Carbon via Particle Surface Area, The International Journal of Powder metallurgy, 30(4) (1994) 399.

Kuroki H, Gang Han and Kenji Shinozaki, Solution-Repreicipitation mechanisms in Fe-Cu-C during liquid phase sintering, The International Journal of Powder metallurgy, 35(2) (1999) 57.

Nayer A., The Metals Data Book, McGraw-Hill, New York, NY, (1997).

MPIF Standard 10: tension test specimens for pressed and sinter metal powders, Standardtest methods for Metal Powders and Powder Metallurgy Products, Metal Powder Industries Federation, Princeton, NJ, USA, (1991).

MPIF Standard 41: Determination of transverse rupture strength of sintered metal powder test specimen, Standard Test methods for Metal Powders and Powder Metallurgy Products, Metal Powder Industries Federation, Princeton, NJ, USA, (1991)

ASM Handbook, Powder Metal Technologies and Applications, ASM International (OH), 7 (1998)

German R M, Powder Metallurgy of Iron and Steel, J. Wiley & Sons Inc., New York, NY, USA, (1998).

Salak Andrej and Riecansky, Ferrous Powder Metallurgy, Cambridge International Science Publishing, (1995).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nekatibeb, F., Raja Annamalai, A. & Upadhyaya, A. Effect of copper and graphite addition on sinterability of iron. Trans Indian Inst Met 64, 81 (2011). https://doi.org/10.1007/s12666-011-0016-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-011-0016-6