Abstract

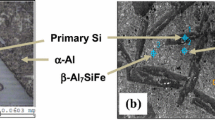

In the present investigation, the mechanical and wear properties of Al-20Si alloy processed by spray casting and vertical centrifugal casting processes have been evaluated and compared. In spray casting process the melt was gas atomized and the spray-deposited over a copper substrate. The spray-deposit exhibited considerable porosity and subjected to hot isostatic pressing to reduce the porosity from 19 to 2%. The centrifugal casting process provided cylindrical shaped preform with characteristically low porosity. The microstructure of spray cast alloy showed ultra fine and uniformly distributed primary and eutectic Si particles in the Al matrix. In contrast, a coarse polyhedral shaped morphology of the primary Si phase was observed in the microstructure of the centrifugal cast alloy. The wear rate of spray cast alloy was invariably lower than that of centrifugal cast alloy. The room temperature tensile and hardness tests of spray cast alloy showed considerable improvement in its strength, ductility and hardness over that of centrifugal cast alloy. The improvement in wear properties of spray cast alloy is discussed in the light of its microstructural modification induced by spray casting and nature of debris particles generated during wear testing.

Similar content being viewed by others

References

Liao H, Sun Yu and Sun G, Mater. Sci. Eng. A, 335 (2002) 62.

Shabestari S G and Moemeni H, J Mater. Proc. Technol., 153–154 (2004) 193.

ASM International, Metal Handbook, 9th Ed. 15 Casting, 296.

Wu Shi Ping, Liu Dong Rong, Guo Jing Jie, Li Chang Yun, Su Yan Qing, Fu Ziegler G, Heinrich J and Wotting G, Mater. Sci. Eng. A, 426(1–2) (2006) 240.

Liu G, Ma Y C, Gao M, Rao G B, Li Y Y and Wei K, Intermetallics, 13 (2005) 925.

Halvaee A and Talebi A, J Mater. Proc. Technol., 118 (2001) 123.

Lavernia E J and Wu Y, Spray atomization and deposition, Wiley, Chichester, U K, (1996).

Grant P S, Prog. Mater. Sci., 39 (1995) 497.

Raju K, Harsha A P and Ojha S N, J of Mat. Sci., 43 (2008) 2509.

Srivastava V C, Mandal R K and Ojha S N, Mater. Sci. Eng. A, 304–306 (2001) 555.

Wu Y, Cassada W A and Lavernia E J, Met. Mat. Trans. A, 26A(5) (1995) 1235.

Srivastava V C, Mandal R K, Ramachandra C, Chatterjee B and Ojha S N, Trans. Ind. Inst. of Metals, 51(1) (1999) 29.

Srivastava V C, Mandal R K and Ojha S N, Mater. Sci. Eng. A, 383 (2004) 14.

Archard J F and Hirst W, in Proc R Soc Lond Ser A, 257 (1964–1965) 51.

Srivastava V C, Rudrakshi G B, Uhlenwinkel V and Ojha S N, J Mater. Sci., 44 (2009) 2288.

Chaudhury S K, Singh A K, Sivaramakrishnan C S and Panigrahi S C, Wear, 258 (2005) 759.

Davis F A and Eyre T S, Tribology Inter, 27(3) (1994) 171.

Amateau M F, Lee D S and Conway J C, in Proc of 3rd Int Conf on Spray casting, Cardiff, UK, (1996) 321.

Prasad B K, Venkateswarlu K, Modi O P, Jha A K, Das S, Dasgupta R and Yegneswaran A H, Met Mat Trans, 29A (1998) 2747.

Jasim K M and Dwarakadasa E S, Wear, 119 (1987) 119.

Dey A K, Poddar P, Singh K K and Sahoo K L, Mater Sci Eng A, 435–436 (2006) 521.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Raju, K., Harsha, A.P. & Ojha, S.N. Effect of processing techniques on the mechanical and wear properties of Al-20Si alloy. Trans Indian Inst Met 64, 1 (2011). https://doi.org/10.1007/s12666-011-0001-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-011-0001-0