Abstract

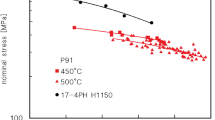

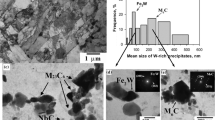

Modern advanced 9–12 % Cr steels are complex alloys with excellent creep strength even at high temperatures up to 620°C. The mechanical properties of these steels are significantly influenced by the presence and stability of various precipitate populations. Numerous secondary phases grow, coarsen and, sometimes, dissolve again during heat treatment and service, which leads to a varying obstacle effect of these precipitates on dislocation movement. In this work, the experimentally observed creep rupture strength of an modified 9–12% Cr steel developed in the European COST Group is compared to the calculated maximal obstacle effect (Orowan stress) caused by the precipitates present in these steels for different heat treatment conditions. It is shown that the differences in creep rupture strength caused by different heat treatments disappear after long time service. This observation is discussed on the basis of the calculated evolution of the precipitate microstructure. The concept of boosting long-term creep rupture strength by maximizing the initial creep strength with optimum quality heat treatment parameters for precipitation strengthening is critically assessed.

Similar content being viewed by others

References

Kern T U, Wieghardt K and Kirchner H, in Advances in Materials Technology for Fossil Power Plants — Proceedings from the Fourth International Conference, (eds) Viswanathan R, Gandy D, Coleman K, ASM International, Ohio (2005) 20.

Masuyama F, in Advances in Materials Technology for Fossil Power Plants — Proceedings from the Fourth International Conference, (eds) Viswanathan R, Gandy D, Coleman K, ASM International, Ohio (2005) 35.

Viswanathan R, Henry J F, Tanzosh J, Stanko G, Shingledecker J and Vitalis V, in Advances in Materials Technology for Fossil Power Plants — Proceedings from the Fourth International Conference, (eds) Viswanathan R, Gandy D, Coleman K, ASM International, Ohio (2005) 3.

Scarlin B, Kern T U and Staubli M, in Advances in Materials Technology for Fossil Power Plants — Proceedings from the Fourth International Conference, (eds) Viswanathan R, Gandy D, Coleman K, ASM International, Ohio (2005) 80.

Bugge J, Kjaer S and Blum R, Energy 31 (2006) 1437.

Kauffmann F, Zies G, Willer D, Scheu C, Maile K, Mayer K H and Straub S, in Proceedings of the 31. MPA-Seminar Werkstoffund Bauteilverhalten in der Energie- & Anlagentechnik, MPA Stuttgart, Stuttgart (2005) 27.1.

Sonderegger B, Characterisation of the Substructure of Modern Power Plant Steels using the EBSD-Method, Ph D Thesis, Graz University of Technology, Austria (2005).

Kozeschnik E and Holzer I, in Creep resistant steels, (eds) Abe F, T.-U. Kern, Viswanathan R, Woodhead Publishing, Cambridge (2008) 305.

Cerjak H, Hofer P, Schaffernak B, Spiradek K, Zeiler G, VGB Kraftwerkstechnik 77(9) (1997) 691.

Kozeschnik E and Buchmayr B, in Mathematical Modelling of Weld Phenomena 5, (ed) Cerjak H, IOM Communications LTD, Oxford (2001) 349.

Svoboda J, Fischer F D, Fratzl P and Kozeschnik E, Mater. Sci. Eng. A 385 (2004) 166.

Kozeschnik E, Svoboda J, Fratzl P and Fischer FD, Mater. Sci. Eng. A 385 (2004) 157.

Kozeschnik E, Svoboda J and Fischer FD, CALPHAD 28 (2005) 379.

McLean M, Acta Metal Mater 33 (1985) 545.

Polcik P, Modellierung des Verformungsverhaltens der warmfesten 9–12% Chromstähle im Temperaturbereich von 550–650°C, Ph D Thesis, Shaker Verlag, Aachen (1999).

Smith C S, Trans AIME, 175 (1948) 15.

Manohar P A, Ferry M and Chandra T, ISIJ International, 38 (1998) 913.

McLean D, Transactions of the Metallurgical Society of AIME 242 (1968) 1193.

Eggeler G, Acta Metal Mater, 37 (1989) 3225.

Sawada K, Takeda M, Maruyama K, Ishii R, Yamada M, Nagae Y and Komine R, Mat Sci Eng A, A267 (1999) 19.

Dimmler G, Quantification of creep resistance and creep fracture strength of 9-12%Cr steel on microstructural basis, Ph D Thesis, Graz University of Technology, Austria (2003).

Èadek J, Creep in metallic materials, Elsevier, Prague (1988).

Ilschner B, Hochtemperatur-Plastizität, Springer Verlag, Berlin/Heidelberg (1973).

Ashby M, in Metallurgical Society Conference, (eds) Ansell G S, Cooper T D and Lenel F V, Gordon and Breach, New York (1968) 143.

Vanstone R W, COST 501/3 WP11 Metallography and alloy design group — Analysis of quantitative data, Internal Report, GEC Alsthom Turbine Generators Limited, Rugby UK (1994).

Rajek J, Computer simulation of precipitation kinetics in solid metals and application to the complex power plant steel CB8, Ph D Thesis, Graz University of Technology, Austria (2005).

Holzer I, Rajek J, Kozeschnik E and Cerjak H, in Proceedings from Materials for advanced power engineering 2006, (eds) Lecomte-Beckers J, Carton M, Schubert F, Ennis PJ, Forschungszentrum Jülich, Jülich (2006), p 1191.

Vodarek V and Strang A, in Proceedings from Materials for advanced power engineering 2002, (eds) Lecomte-Beckers J, Carton M, Schubert F, Ennis PJ, Forschungszentrum Jülich, Jülich (2002) 1223.

TCFE3 thermodynamic database, Thermo-Calc Software AB, Stockholm, Sweden, (1992–2004).

Hofer P, Mikrostrukturelle Analyse als Basis für die Entwicklung neuer Kraftwerkswerkstoffe am Beispiel von G-X12 CrMoWVNbN 10-1-1, Ph D Thesis, Graz University of Technology, Austria (1999).

Danielsen H K, Hald J, Grumsen F G, Somers M A J, Metall Mater Trans., 37A (2006) 2633.

Guntz G, Julien M, Kottmann G, Pellicani F, Pouilly A and Vaillant JC, The T 91 Book — Ferritic tubes and pipe for high temperature use in boilers, Vallourec Industries, France (1991).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Holzer, I., Kozeschnik, E. & Cerjak, H. New approach to predict the long-term creep behaviour and evolution of precipitate back-stress of 9–12% chromium steels. Trans Indian Inst Met 63, 137–143 (2010). https://doi.org/10.1007/s12666-010-0019-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-010-0019-8