Abstract

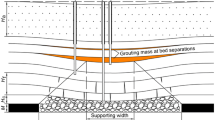

The Isolated Overburden Grout Injection Technology is employed for the "Three down" coal resource mining, ground subsidence management, and fly ash waste treatment, exemplifying the concept of environmentally friendly mining. The analysis of Isolated Overburden Grout Injection Technology can be effectively conducted utilizing the large-deflection inclined thin plate combined with the slurry model. However, differences in stratigraphic parameters, such as main roof and principal key strata (PKS), among different mines, as well as variations in design parameters like working face dimensions, mining height, coal seam angle of inclination, mining speed, and grouting parameters such as the number of grouting holes, start and finish times. These parameters lead to variations in outcomes such as PKS deflection and Bed-separation development, as well as the maximum subsidence and extent of the ground subsidence basin. To guarantee accurate and effective safeguarding of village structures, exploitation of coal resources, and appropriate management of fly ash waste, it is crucial to assess each parameter's influence in the model thoroughly. This analysis aims to clarify the mining and grouting process and enhance the logical design of the essential parameters. This paper classifies and examines the influence of each parameter on the results, utilizing the case study of the 7221 work face grouting operations in Huaibei, Anhui Province, China. The mining and grouting parameters were re-optimized to meet the protection requirements of the Gaochangying and Houlou Gaojia villages. The changes assessed the possible advantages of enhancing the initial design of coal seam resources and including fly ash backfill.

Similar content being viewed by others

Data availability

The current study's data and source code can be found in this published article and its supplementary information file. The datasets generated and analyzed in the recent research and the source code are also available upon reasonable request to the corresponding authors.

References

Alehossein H (2009) Viscous, cohesive, non-Newtonian, depositing, radial slurry flow. Int J Miner Process 93(1):11–19. https://doi.org/10.1016/j.minpro.2009.04.006. (in English)

Bo HZ et al (2023) Study on surface subsidence prediction method of shallow coal seam backfill-strip mining under the hard roof. Bull Eng Geol Environ 82(7):12. https://doi.org/10.1007/s10064-023-03284-3. (Art no. 281, in English)

Huang YC, Feng RM, Wang HP, Zhao WP, Liu YF (2011) the coal mining mode of paste-like fill and its application prospects. In: International Conference on civil engineering and building materials (CEBM), Kunming, PEOPLES R CHINA, Jul 29–31 2011, vol. 255–260, STAFA-ZURICH: Trans Tech Publications Ltd, in Advanced Materials Research, 2011, pp. 3744–3748, https://doi.org/10.4028/www.scientific.net/AMR.255-260.3744. [Online]. Available: <Go to ISI>://WOS:000302894902055

Jiang HQ, Fall M, Li YH, Han J (2019) An experimental study on compressive behaviour of cemented rockfill. Constr Build Mater 213:10–19. https://doi.org/10.1016/j.conbuildmat.2019.04.061. (in English)

Ju JF, Xu JL (2013) Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 70 m height chocks. Int J Rock Mech Min Sci 58:46–54. https://doi.org/10.1016/j.ijrmms.2012.09.006. (in English)

Li WX, Gao CY, Yin X, Li JF, Qi DL, Ren JC (2015) A visco-elastic theoretical model for analysis of dynamic ground subsidence due to deep underground mining. Appl Math Model 39(18):5495–5506. https://doi.org/10.1016/j.apm.2015.01.003. (in English)

Li Z, Xu JL, Ju JF, Zhu WB, Xu JM (2018) The effects of the rotational speed of voussoir beam structures formed by key strata on the ground pressure of stopes. Int J Rock Mech Min Sci 108:67–79. https://doi.org/10.1016/j.ijrmms.2018.04.041. (in English)

Li Z, Feng GR, Cui JQ (2020) Research on the influence of slurry filling on the stability of floor coal pillars during mining above the room-and-pillar goaf: a case study. Geofluids. https://doi.org/10.1155/2020/8861348. (Art no. 8861348, in English)

Li J, Xuan DY, Xu JL, Dong ZB, Wang CC (2023) Compaction response of mining-induced rock masses to longwall overburden isolated grouting. Minerals 13(5):15. https://doi.org/10.3390/min13050633. (Art no. 633, in English)

Liu Y, Guo WJ, Chen JT (2012) Study on the technique of filling paste into mine goaf with building waste. In: 2nd International Conference on Applied Mechanics, Materials and Manufacturing (ICAMMM 2012), Changsha, PEOPLES R CHINA, Nov 17–18 2012, vol. 268–270, STAFA-ZURICH: Trans Tech Publications Ltd, in Applied Mechanics and Materials, 2013, pp 656–659, doi: https://doi.org/10.4028/www.scientific.net/AMM.268-270.656. [Online]. Available: <Go to ISI>://WOS:000320476800136

Palarski J (1989). The experimental and practical results of applying backfill. In: Hassani FP, Scoble MJ, Yu TR (eds) Innovations in mining backfill technology—Proceeding of the 4th International Symposium on Mining with Backfill. Rotterdam: Balkema, 1989, pp 33–37

Qian M, Xu J, Miao X (2003) Green technique in coal mining. J China Univ Min Technol 32(4):343–348

Tan YL, Liu XS, Ning JG, Tian CL (2015) Front abutment pressure concentration forecast by monitoring cable-forces in the roof. Int J Rock Mech Min Sci 77:202–207. https://doi.org/10.1016/j.ijrmms.2015.04.002. (in English)

Wang YX et al (2022) "Reform and development of coal mine safety in China: an analysis from government supervision, technical equipment, and miner education. Resour Policy 77:14. https://doi.org/10.1016/j.resourpol.2022.102777. (Art no. 102777, in English)

Wang BL, Xu JL, Xuan DY (2018) Time function model of dynamic surface subsidence assessment of grout-injected overburden of a coal mine. Int J Rock Mech Min Sci 104:1–8. https://doi.org/10.1016/j.ijrmms.2018.01.044. (in English)

Xu J, Xuan D, Zhu W (2015) Study and application of coal mining with partial backfilling. J China Coal Soc 40(6):1303–1312

Xuan DY, Xu JL (2017) Longwall surface subsidence control by technology of isolated overburden grout injection. Int J Min Sci Technol 27(5):813–818. https://doi.org/10.1016/j.ijmst.2017.07.014. (in English)

Xuan DY, Xu JL, Wang BL, Teng H (2015) Borehole investigation of the effectiveness of grout injection technology on coal mine subsidence control. Rock Mech Rock Eng 48(6):2435–2445. https://doi.org/10.1007/s00603-015-0710-5. (in English)

Xuan DY, Xu JL, Wang BL, Teng H (2016) Investigation of fill distribution in post-injected longwall overburden with implications for grout take estimation. Eng Geol 206:71–82. https://doi.org/10.1016/j.enggeo.2016.04.007. (in English)

Xuan DY, Li J, Zheng KD, Xu JL (2020) Experimental study of slurry flow in mining-induced fractures during longwall overburden grout injection. Geofluids. https://doi.org/10.1155/2020/8877616. (Art no. 8877616, in English)

Yang SM, Zhang GR (2012), Study on technologies and countermeasures of comprehensive utilization of coal resources. In: International Conference on sustainable energy and environmental engineering (ICSEEE 2012), Guangzhou, PEOPLES R CHINA, Dec 29–30 2012, vol. 295–298, STAFA-ZURICH: Trans Tech Publications Ltd, in Applied Mechanics and Materials, 2013, pp. 3001–3004, doi: https://doi.org/10.4028/www.scientific.net/AMM.295-298.3001. [Online]. Available: <Go to ISI>://WOS:000320828201247

Yin W, Wang JQ, Bai XM, Sun WJ, Zhou ZY (2020) Strata behavior and control strategy of backfilling collaborate with caving fully- mechanized mining. Open Geosci. 12(1):703–717. https://doi.org/10.1515/geo-2020-0168. (in English)

Zhao DS, Xu T, Tang CA, Fan XL (2001) Numerical simulation of bed separation of overburden strata induced by mining excavation. In: ISRM International Symposium/3rd Asian Rock Mechanics Symposium (ARMS), Kyoto, JAPAN, Nov 30-Dec 02 2004, ROTTERDAM: Millpress Science Publishers, 2004, pp 475–478. [Online]. Available: <Go to ISI>://WOS:000228664700075. [Online]. Available: <Go to ISI>://WOS:000228664700075

Zhu JM, Ma ZW, Xu JH, Wu JN (2011) Research on the technology of filling and repeated mining in thick coal seam affected by small mine gob area. In: 1st International Symposium on Mine Safety Science and Engineering (ISMSSE), Beijing, PEOPLES R CHINA, Oct 26–29 2011, vol. 26, AMSTERDAM: Elsevier Science Bv, in Procedia Engineering, 2011, https://doi.org/10.1016/j.proeng.2011.11.2285. [Online]. Available: <Go to ISI>://WOS:000300848300153

Zhu WB, Xu JM, Xu JL, Chen DY, Shi JX (2017) Pier-column backfill mining technology for controlling surface subsidence. Int J Rock Mech Min Sci 96:58–65. https://doi.org/10.1016/j.ijrmms.2017.04.014. (in English)

Acknowledgements

The authors are grateful to anonymous reviewers for their valuable suggestions.

Funding

This research was supported by the Entrusted Project of Huaibei Mining Co., Ltd. (2023–129) and the National Natural Science Foundation of China [41971401].

Author information

Authors and Affiliations

Contributions

LI modeling article writing, MA provided study area and data, YANG provided financial support and writing guidance, JIANG gave advice on paper writing, GU, PENG, CHEN article review and submission work

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Yx., Ma, J., Yang, Km. et al. Isolated overburden grout injection technology mining and grouting parameters discussion and optimization. Environ Earth Sci 83, 264 (2024). https://doi.org/10.1007/s12665-024-11465-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-024-11465-w