Abstract

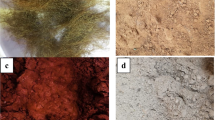

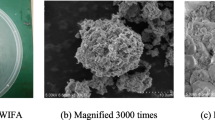

This study proposes a novel approach by integrating geopolymerized bagasse ash (GBA) and geopolymerized quarry dust (GQD) along with shredded facemasks (FM) for the balanced amelioration of fat clay. Extensive geotechnical testing and mineralogical and microstructural analyses were conducted to assess the performance of the proposed multi-waste fat clay stabilizer. GBA and GQD were found to reduce the liquid limit (wL) and plasticity index (IP) of fat clay up to 12% and 30% of their weight by soil, respectively, based on which composite binary additive (CBA) was devised for which optimum binary additive (OBA) was found at 20% of CBA. The strength characteristics, i.e., unconfined compressive strength (qu), CBR value, and yield stress (σy) of soil treated with OBA were observed to be significantly higher than that of untreated soil. Meanwhile, the combination of OBA and FM increased the strength more than OBA up to 0.2% of FM, after which a slight decrease was observed. The stress–strain curve, brittleness index (IB), and ductility index (ID) of the OBA-treated fat clay showed a brittle failure response, which was transformed into a ductile response as FM increased in OBA cum FM stabilizer. Microstructural analysis showed the formation of flocculation, reticulation, and cementitious gel in the treated soil. Mineralogical and elemental analyses confirmed the formation of (N, C)–A–S–H gel in the fat clay, primarily responsible for the strength gain of the treated soil. The microstructural analysis also evidenced the FM strings in the microstructure responsible for maintaining the ductility of soil. Also, the proposed multi-waste recycling has significant implications for waste management, as its implementation for the construction of a two-lane subgrade covering a distance of 1 km may enable the repurposing of 1188.58 tons of assorted solid waste.

Similar content being viewed by others

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- ASTM:

-

American society for testing and materials

- CBA:

-

Composite binary additive

- CBR:

-

California bearing ratio

- C c :

-

Compression index

- EDAX:

-

Energy-dispersive X-ray analysis

- e :

-

Void ratio

- e 0 :

-

Initial void ratio

- GBS:

-

Geopolymerized bagasse ash

- GQD:

-

Geopolymerized quarry dust

- GSD:

-

Grain size distribution

- I B :

-

Brittleness index

- I D :

-

Deformability index

- I P :

-

Plasticity index

- FM:

-

Facemask

- OBA:

-

Optimum binary additive

- q u :

-

Unconfined compressive strength

- q r :

-

Residual compressive strength

- R 2 :

-

Coefficient of determination

- SEM:

-

Scanning electron microscopy analysis

- USCS:

-

Unified soil classification system

- W-D :

-

Wetting drying

- w :

-

Water content

- w L :

-

Liquid limit

- w n :

-

Natural water content

- w opt :

-

Optimum moisture content

- w P :

-

Plastic limit

- XRD:

-

X-ray diffraction analysis

- ε a :

-

Axial strain

- ε f :

-

Strain at failure

- γ d :

-

Dry unit weight

- γ dmax :

-

Maximum dry unit weight

- σ :

-

Stress

- σ v ' :

-

Effective vertical stress

- σ y :

-

Yield stress

References

Abdi MR, Abbas G, Leila SC (2021) An investigation into the effects of lime on compressive and shear strength characteristics of fiber-reinforced clays. J Rock Mech Geotech Eng 13(4):885–898. https://doi.org/10.1016/j.jrmge.2020.11.008

Abdullah HH, Shahin MA, Walske ML, Karrech A (2019) Systematic approach to assessing the applicability of fly-ash-based geopolymer for clay stabilization. Can Geotech J. https://doi.org/10.1139/cgj-2019-0215

Adhikari B, Khattak MJ, Adhikari S (2021) Mechanical and durability characteristics of flash-based soil-geopolymer mixtures for pavement base and subbase layers. Int J Pavement Eng 22(9):1193–1212. https://doi.org/10.1080/10298436.2019.1668562

Ajala EO, Ighalo JO, Ajala MA, Adeniyi AG, Ayanshola AM (2021) Sugarcane bagasse: a biomass sufficiently applied for improving global energy, environment and economic sustainability. Bioresour Bioprocess 8(1):1–25. https://doi.org/10.1186/s40643-021-00440-z

Ammendolia J, Saturno J, Brooks AL, Jacobs S, Jambeck JR (2021) An emerging source of plastic pollution: environmental presence of plastic personal protective equipment (PPE) debris related to COVID-19 in a metropolitan city. Environ Poll 269:116160. https://doi.org/10.1016/j.envpol.2020.116160

Amulya G, Moghal AAB, Almajed A (2022a) Sustainable binary blending for low-volume roads—reliability-based design approach and carbon footprint analysis. Materials 16(5):2065. https://doi.org/10.3390/ma16052065

Amulya G, Moghal AAB, Basha BM, Almajed A (2022b) Coupled effect of granite sand and calcium lignosulphonate on the strength behavior of cohesive soil. Buildings 12(10):1687. https://doi.org/10.3390/buildings12101687

Ashfaq M, Moghal AAB (2022) Cost and carbon footprint analysis of flyash utilization in earthworks. Int J Geosynth Ground Eng 8:21. https://doi.org/10.1007/s40891-022-00364-4

ASTM D698 (2021) Standard test methods for laboratory compaction characteristics of soil using standard effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International, West Conshohocken, PA, USA

ASTM D1557 (2021) Standard test methods for laboratory compaction characteristics of soil using modified effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)). ASTM International, ASTM International, West Conshohocken, PA, USA

ASTM D1883 (2021) Standard test method for California bearing ratio (CBR) of laboratory-compacted soils. ASTM International, West Conshohocken, PA, USA

ASTM D2166 (2016) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken, PA, USA

ASTM D2435 (2011) Standard test methods for one-dimensional consolidation properties of soils using incremental loading. ASTM International, West Conshohocken, PA, USA

ASTM D2487 (2017) Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). ASTM International, West Conshohocken, PA, USA

ASTM D4318 (2017) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM International, West Conshohocken, PA, USA

ASTM D6913 (2017) Standard test methods for particle-size distribution (gradation) of soils using sieve analysis. ASTM International, West Conshohocken, PA, USA

ASTM D7928 (2021) Standard test method for particle-size distribution (gradation) of fine-grained soils using the sedimentation (hydrometer) analysis. ASTM International, West Conshohocken PA, USA

Athira G, Bahurudeen A (2022) Rheological properties of cement paste blended with sugarcane bagasse ash and rice straw ash. Constr Build Mater 332:127377. https://doi.org/10.1016/j.conbuildmat.2022.127377

Attom MF, Al-Sharif MM (1998) Soil stabilization with burned olive waste. Appl Clay Sci 13:219–230. https://doi.org/10.1016/S0169-1317(98)00007-6

Bell FG (1993) Engineering treatment of soils, published by E and FN spon, an imprint of chapmen and hall, Boundary Row, London. https://doi.org/10.1201/9781482288971

Chen R, Ng CWW (2013) Impact of wetting–drying cycles on hydro-mechanical behavior of an unsaturated compacted clay. Appl Clay Sci 86:38–46. https://doi.org/10.1016/j.clay.2013.09.018

Chen B, Zhu R, Chang FZ (2011) Microstructural characteristics of volumetric deformation of clay under different compression stresses. Rock Soil Mech 32(1):95–100

Chen Z, Feng Q, Yue R, Chen Z, Moselhi O, Soliman A, Hammad A, An C (2022) Construction, renovation, and demolition waste in landfill: a review of waste characteristics, environmental impacts, and mitigation measures. Environ Sci Pollut Res 29(31):46509–46526. https://doi.org/10.1007/s11356-022-20479-5

Cheng Q, Tang CS, Xu D, Zeng H, Shi B (2021) Water infiltration in a cracked soil considering effect of drying-wetting cycles. J Hydrol 593:125640. https://doi.org/10.1016/j.jhydrol.2020.125640

Cristelo N, Glendinning S, Fernandes LSG, Pinto AT (2013) Effects of alkaline-activated fly ash and Portland cement on soft soil stabilisation. Acta Geotech 8:395–405. https://doi.org/10.1007/s11440-012-0200-9

Davidovits J (1994) Properties of geopolymer cements. In: First international conference on alkaline cements and concretes

Dey S, Anand U, Kumar V, Kumar S, Ghorai M, Ghosh A, Kant N, Suresh S, Bhattacharya S, Bontempi E, Bhat SA, Dey A (2023) Microbial strategies for degradation of microplastics generated from COVID-19 healthcare waste. Environ Res 216(P1):114438. https://doi.org/10.1016/j.envres.2022.114438

Dharmaraj S, Ashokkumar V, Hariharan S, Manibharathi A, Show PL, Chong CT, Ngamcharussrivichai C (2021) The COVID-19 pandemic facemask waste: a blooming threat to the marine environment. Chemosphere 272:129601. https://doi.org/10.1016/j.chemosphere.2021.129601

Dhawan R, Bisht BMS, Kumar R, Kumari S, Dhawan SK (2019) Recycling of plastic waste into tiles with reduced flammability and improved tensile strength. Process Saf Environ Prot 124:299–307. https://doi.org/10.1016/j.psep.2019.02.018

Franca S, Figueriredo RF, Sousa LN, Silva MVMS, Borges PHR, Bezerra ACS (2023) Reaction mechanisms in geopolymers produced from sugarcane bagasse ash. Constr Build Mater 377:131124. https://doi.org/10.1016/j.conbuildmat.2023.131124

Garcia-Lodeiro I, Fernandez-Jiménez A, Palomo A (2013) Variation in hybrid cements over time. Alkaline activation of fly ash–portland cement blends. Cem Concr Res 52:112–122. https://doi.org/10.1016/j.cemconres.2013.03.022

Gu J, Liu X, Zhang Z (2023) Road base materials prepared by multi-industrial solid wastes in China: a review. Constr Build Mater 373:130860. https://doi.org/10.1016/j.conbuildmat.2023.130860

Hamza M, Farooq K, Rehman ZU, Mujtaba H, Khalid U (2023) Utilization of eggshell food waste to mitigate geotechnical vulnerabilities of fat clay: a micro–macro-investigation. Environ Earth Sci 82(10):247. https://doi.org/10.1007/s12665-023-10921-3

Hardjito D, Wallah SE, Sumajouw DMJ, Rangan BV (2004) On the development of fly ash-based geopolymer concrete. ACI Materials J 101(6):467–472. https://doi.org/10.14359/13485

Hemmati S, Gatmiri B, Cui YJ, Vincent M (2012) Thermo-hydro mechanical modelling of soil settlements induced by soilvegetation—atmosphere interactions. Eng Geol 139–140:1–16. https://doi.org/10.1016/j.enggeo.2012.04.003

Hov S, Paniagua P, Sætre C, Rueslåtten H, Størdal L, Mengede M, Mevik C (2022) Lime-cement stabilisation of Trondheim clays and its impact on carbon dioxide emissions. Soils Found 62(3):101162. https://doi.org/10.1016/j.sandf.2022.101162

Ijaz N, Dai F, Ur Rehman Z (2020) Paper and wood industry waste as a sustainable solution for environmental vulnerabilities of fat clay: a novel approach. J Environ Manage 262:110285. https://doi.org/10.1016/j.jenvman.2020.110285

Ijaz N, Ye W, Ur Rehman Z, Ijaz Z (2022a) Novel application of low carbon limestone calcined clay cement(LC3) in expansive soil stabilization: An eco-efficient approach. J Clean Prod 371:133492. https://doi.org/10.1016/j.jclepro.2022.133492

Ijaz N, ur Rehman Z, Ijaz Z, (2022b) Recycling of paper/wood industry waste for hydromechanical stability of expansive soils: A novel approach. J Clean Prod 348:131345. https://doi.org/10.1016/j.jclepro.2022.131345

Ijaz N, Ye W, Ur Rehman Z, Dai F, Ijaz Z (2022c) Numerical study on stability of lignosulphonate-based stabilized surficial layer of unsaturated expansive soil slope considering hydro-mechanical effect. Transp Geotech 32:100697. https://doi.org/10.1016/j.trgeo.2021.100697

Ijaz N, Ye W, Rehman ZU, Ijaz Z, Junaid MF (2023) New binary paper/wood industry waste blend for solidification/stabilisation of problematic soil subgrade: macro-micro study. Road Mater Pavement Des 24(5):1215–1232. https://doi.org/10.1080/14680629.2022.2064905

Jayasundara RBCD, Udayagee KPP, Karunarathna AK, Manage PM, Nugara RN, Abhayapala KMRD (2023) Permeable reactive barriers as an in situ groundwater remediation technique for open solid waste dumpsites: a review and prospect. Wat Air Soil Poll 234(1):50. https://doi.org/10.1007/s11270-022-06056-z

Kalkan E, Akbulut S (2004) The positive effects of silica fume on the permeability, swelling pressure and compressive strength of natural clay liners. Eng Geo 73:145–156. https://doi.org/10.1016/j.enggeo.2004.01.001

Koniorczyk M, Bednarska D, Masek A, Cichosz S (2022) Performance of concrete containing recycled masks used for personal protection during coronavirus pandemic. Constr Build Mater 324:126712. https://doi.org/10.1016/j.conbuildmat.2022.126712

Kumar P, Kumar NV (2018) Soil Stabilization using lime and quarry dust. Int J Innov Res Stud 8(1):103–111, https://www.pramanaresearch.org/gallery/12.jan.ijirs.d516.pdf (Accessed 01 Jan 2023)

Khalid U, Rehman Z (2018) Evaluation of compaction parameters of fine-grained soils using standard and modified efforts. Int J Geo-Eng 9(1):1–17. https://doi.org/10.1186/s40703-018-0083-1

Khalid U, Ye GL, Yadav SK, Yin ZY (2019) A simple experimental method to regain the mechanical behavior of naturally structured marine clays. Appl Ocean Res 88:275–287. https://doi.org/10.1016/j.apor.2019.04.012

Khalid U, Ye G, Yadav SK, Zhou A, Gu LL (2021) Consolidation pressure consequences on the soil structure of artificial structured marine clay: macro and micro evaluation. Geotech Geol Eng 39:247–263. https://doi.org/10.1007/s10706-020-01489-x

Khalid U, Rehman Z, Mujtaba H, Farooq K (2022) 3D response surface modeling based in-situ assessment of physico-mechanical characteristics of alluvial soils using dynamic cone penetrometer. Transp Geotech 36:100781. https://doi.org/10.1016/j.trgeo.2022.100781

Khalid U, Rehman ZU, Ullah I, Khan K, Kayani WI (2023a) Efficacy of geopolymerization for integrated bagasse ash and quarry dust in comparison to fly ash as an admixture: A comparative study. J Eng Res https://doi.org/10.1016/j.jer.2023.08.010

Khalid U, Rehman ZU, Ijaz N, Khan I, Junaid MF (2023b) Integrating wheat straw and silica fume as a balanced mechanical ameliorator for expansive soil: a novel agri-industrial waste solution. Environ Sci Pollut Res 30:73570–73589. https://doi.org/10.1007/s11356-023-27538-5

Lam MNT, Le DH, Naguyen DL (2023) Reuse of clay brick and ceramic waste in concrete: a study on compressive strength and durability using the Taguchi and Box-Behnken design method. Constr Build Mater 373:130801. https://doi.org/10.1016/j.conbuildmat.2023.130801

Li J, Tang C-S, Wang D, Pei X, Shi B (2014) Effect of discrete fibre reinforcement on soil tensile strength. J Rock Mech Geotech Eng 6:133–137. https://doi.org/10.1016/j.jrmge.2014.01.003

Li S, Wang S, Tang C, Chen Y (2023) Optimization of synergy between cement, slag, and phosphogypsum for marine soft clay solidification. Constr Build Mater 374:130902. https://doi.org/10.1016/j.conbuildmat.2023.130902

Liu Z, Wang J, Yang X, Huang Q, Zhu K, Sun Y, Van Hulle S, Jia H (2022) Generation of environmental persistent free radicals (EPFRs) enhances ecotoxicological effects of the disposable facemask waste with the COVID-19 pandemic. Environ Poll 301:119019. https://doi.org/10.1016/j.envpol.2022.119019

Mariadass S (2023) Investigation on fat clay problems associated with damages in low rise buildings along south east coast of investigation on fat clay problems associated with damages in low rise buildings along south east coast of India : a geotechnical mappin. https://doi.org/10.9734/bpi/taier/v7/3959C

Mitchell JK, Soga K (2005) Fundamentals of soil behavior. 3rd edition, John Wiley & Sons. https://www.wiley.com/en-us/Fundamentals+of+Soil+Behavior%2C+3rd+Edition-p-9780471463023 (Accessed 01 Jan 2023)

Muensterman DJ, Cahuas L, Titaley IA, Schmokel C, De La Cruz FB, Barlaz MA, Carignan CC, Peaslee GF, Field JA (2022) Per- and polyfluoroalkyl substances (PFAS) in facemasks: potential source of human exposure to PFAS with implications for disposal to landfills. Environ Sci Technol Lett 9(4):320–326. https://doi.org/10.1021/acs.estlett.2c00019

Mujtaba H, Khalid U, Farooq K, Elahi M, Rehman Z, Shahzad HM (2020) Sustainable utilization of powdered glass to improve the mechanical behavior of fat clay. KSCE Journal of Civil Engineering 24(12):3628–3639. https://doi.org/10.1007/s12205-020-0159-2

Nzediegwu C, Chang SX (2020) Improper solid waste management increases potential for COVID-19 spread in developing countries. Resour Conserv Recycl 161:104947

Oliveira AM, Patrício Silva AL, Soares AMVM, Barceló D, Duarte AC, Rocha-Santos T (2023) Current knowledge on the presence, biodegradation, and toxicity of discarded facemasks in the environment. J Environ Che Eng 11(2):109308. https://doi.org/10.1016/j.jece.2023.109308

Pasculli A, Sciarra N, Esposito L, Esposito AW (2017) Effects of wetting and drying cycles on mechanical properties of pyroclastic soils. CATENA 156:113–123. https://doi.org/10.1016/j.catena.2017.04.004

Pilegis M (2014), Structural and geo-environmental applications of waste quarry dust, Doctoral Dissertation, Cardiff University, Wales, United Kingdom

Rehman Z, Khalid U (2021) Reuse of COVID-19 facemask for the amelioration of mechanical properties of fat clay: a novel solution to an emerging waste problem. Sci Total Environ 794:148746. https://doi.org/10.1016/j.scitotenv.2021.148746

Rehman ZU, Khalid U (2022) Optimization of COVID-19 facemask waste fibers and silica fume as a balanced mechanical ameliorator of fat clay using response surface methodology. Environ Sci Pollut Res 29(12):17001–17016. https://doi.org/10.1007/s11356-021-16912-w

Rehman ZU, Junaid MF, Ijaz N, Khalid U, Ijaz Z (2023) Remediation methods of heavy metal contaminated soils from environmental and geotechnical standpoints. Sci Tot Environ 867:161468. https://doi.org/10.1016/j.scitotenv.2023.161468

Rehman ZU, Junaid MF, Ijaz N, Khalid U, Ijaz Z (2023a) Remediation methods of heavy metal contaminated soils from environmental and geotechnical standpoints. Sci Tot Environ 867:161468. https://doi.org/10.1016/j.scitotenv.2023.161468

Rehman ZU, Ijaz N, Ye W, Ijaz Z (2023b) Design optimization and statistical modeling of recycled waste-based additive for a variety of construction scenarios on heaving ground. Environ Sci Pollut Res 30(14):39783–39802. https://doi.org/10.1007/s11356-022-24853-1

Rios S, Ramos C, Da Fonseca AV, Cruz N, Rodrigues C (2017) Mechanical and durability properties of a soil stabilised with an alkali-activated cement. Eur J Environ Civ Eng 23:245–267. https://doi.org/10.1080/19648189.2016.1275987

Rowles MR, O’Connor BH (2009) Chemical and structural microanalysis of aluminosilicate geopolymers synthesized by sodium silicate activation of metakaolinite. J Am Ceram Soc 92:2354

Saberian M, Li J, Kilmartin-Lynch S, Boroujeni M (2021) Repurposing of COVID-19 single-use facemasks for pavements base/subbase. Sci Total Environ 769:145527. https://doi.org/10.1016/j.scitotenv.2021.145527

Sargent P (2015) The development of alkali-activated mixtures for soil stabilisation. In: Handbook of Alkali-Activated Cements, Mortars and Concretes. Elsevier BV: Amst. Neth. 54:555–604. https://doi.org/10.1016/C2013-0-16511-7

Saride S, Puppala AJ, Chikyala SR (2013) Swell-shrink and strength behaviors of lime and cement stabilized expansive organic clays. Appl Clay Sci 85:39–45. https://doi.org/10.1016/j.clay.2013.09.008

Shah MM, Shahzad HM, Khalid U, Farooq K, Ur Rehman Z (2023) Experimental study on sustainable utilization of CKD for improvement of collapsible soil. Arab J Sci Eng 8:5667–5682. https://doi.org/10.1007/s13369-022-07565-z

Silva ALP, Prata JC, Walker TR, Campos D, Duarte AC, Soares AM, RochaSantos T (2020) Rethinking and optimising plastic waste management under COVID-19 pandemic: policy solutions based on redesign and reduction of single-use plastics and personal protective equipment. Sci Total Environ 742:140565. https://doi.org/10.1016/j.scitotenv.2020.140565

Tang C-S, Shi B, Cui Y-J, Liu C, Gu K (2012) Desiccation cracking behavior of polypropylene fiber–reinforced clayey soil. Can Geotech J 49:1088–1101. https://doi.org/10.1139/T2012-067

Tang CS, Cheng Q, Leng T, Shi B, Zeng H, Inyang HI (2020) Effects of wetting-drying cycles and desiccation cracks on mechanical behavior of an unsaturated soil. CATENA 194:104721. https://doi.org/10.1016/j.catena.2020.104721

The World Banf Report (2018) Trends in solid waste management. WHAT A WASTE 2.0, A global snapshot of solid waste management to 2050. https://datatopics.worldbank.org/what-a-waste/trends_in_solid_waste_management.html. Accessed 07 Aug 2023

Tiwari N, Satyam N, Singh K (2020a) Effect of curing on micro-physical performance of polypropylene fiber reinforced and silica fume stabilized fat clay under freezing thawing cycles. Sci Rep 10(1):1–16

Tiwari B, Ye G, Li M, Khalid U, Yadav SK (2020b) Strength and dilatancy behaviors of deep sands in Shanghai with a focus on grain size and shape effect. J Rock Mech Geotech Eng 12:1214–1225. https://doi.org/10.1016/j.jrmge.2020.01.010

Vanapalli KR, Sharma HB, Ranjan VP, Samal B, Bhattacharya J, Dubey BK, Goel S (2021) Challenges and strategies for effective plastic waste management during and post COVID-19 pandemic. Sci Total Environ 750:141514. https://doi.org/10.1016/j.scitotenv.2020.141514

Yi Y, Zheng X, Liu S, Al-Tabbaa A (2015) Comparison of reactive magnesia- and carbide slag-activated ground granulated blastfurnace slag and Portland cement for stabilisation of a natural soil. Appl Clay Sci 111:21–26. https://doi.org/10.1016/j.clay.2015.03.023

Yin Z-Y, Jin YF, Shen SL, Huang HW (2016) An efficient optimization method for identifying parameters of soft structured clay by an enhanced genetic algorithm and elastic-viscoplastic model. Acta Geotech 12(4):849–867. https://doi.org/10.1007/s11440-016-0486-0

Zhu QY, Yin ZY, Hicher PY, Shen SL (2015) Nonlinearity of one-dimensional creep characteristics of soft clays. Acta Geotech 11(4):887–900. https://doi.org/10.1007/s11440-015-0411-y

Acknowledgements

NUST Risalpur is acknowledged for technical support.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

IU: Conceptualization, Methodology, Data Curation, Laboratory Testing, Formal analysis, Visualization. UK: Conceptualization, Validation, Data Curation, Writing original draft, Formal analysis, Visualization. ZuR: Conceptualization, Validation, Data Curation, Writing–review & editing, Visualization. MM: Validation, Data Curation, Writing–review & editing, IK: Validation, Data Curation, Writing–review & editing, NI: Validation, Data Curation, Writing–review & editing, Visualization.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ullah, I., Khalid, U., Rehman, Z.u. et al. Integrated recycling of geopolymerized quarry dust and bagasse ash with facemasks for the balanced amelioration of the fat clay: a multi-waste solution. Environ Earth Sci 82, 516 (2023). https://doi.org/10.1007/s12665-023-11219-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-023-11219-0