Abstract

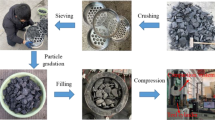

Compaction properties of the backfill body are the key to reveal the law of roof subsidence and illustrate the mechanism of ground pressure control with gangue backfill mining. A rock mechanic testing machine and a self-designed steel cylinder were applied to conduct compaction experiments of gangue with different particle sizes, axial stresses, loading rates decided by actual mining stress in goaf. The characteristics of stress–strain, fractal dimension and energy dissipation for crushed gangue were analyzed. The stress–strain relationship of crushed gangue in the compaction process increases exponentially and can be divided into void compaction stage, structure adjustment stage and elastoplastic deformation stage. The fractal dimension will increase with the increase of axial stress, and decrease with the increase of loading rate. The energy dissipation in the process of gangue sample compaction depends on the stress–strain characteristics, that is resistance to axial deformation. Based on the experimental results, gangue particle size gradation has a more significant influence on compaction characteristics of gangue more than axial stress and loading rate. The axial strain caused by particle size ranges from 0.19 to 0.51, and the energy dissipation exceeds the range of 5 times, which are far beyond the influence of other factors.

Similar content being viewed by others

Data availability

Enquiries about data availability should be directed to the authors.

References

Bauer E (2009) Hypoplastic modelling of moisture-sensitive weathered rockfill materials. Acta Geotech 4:261–272

Chen J, Shi K, Pu Y, Apel DB, Zhang C, Zuo Y, Song L (2023) Study on instability fracture and simulation of surrounding rock induced by fault activation under mining influence. Rock Mechanics Bulletin 2(2):100037

Chu TX, Li P, Chao JK, Yu MG, Han XF (2017) Bulking coefficient evolution characteristics and mechanism of compacted broken coal. J China Coal Soc 42:3182–3188

Han P, Zhang C, Ren Z, He X, Jia S (2021) The influence of advance speed on overburden movement characteristics in longwall coal mining: insight from theoretical analysis and physical simulation. J Geophys Eng 18(1):163–176

He MC, Yang GX, Miao JL, Jia XN, Jiang TT (2009) Classification and research methods of rockburst experimental fragments. Chin J Rock Mech Eng 28:1521–1529

Huang YL, Li JM, Teng YC, Dong XJ, Wang X, Kong GQ, Song TQ (2017) Numerical simulation study on macroscopic mechanical behaviors and micro-motion characteristics of gangues under triaxial compression. Powder Technol 320:668–684

Huang P, Zhang J, Yan X, Spearing AJS, Li M, Liu S (2021) Deformation response of roof in solid backfilling coal mining based on viscoelastic properties of waste gangue. Int J Min Sci Technol 31(2):279–289

Li M, Zhang JX, Zhou N, Huang YL (2017) Effect of particle size on the energy evolution of crushed waste rock in coal mines. Rock Mech Rock Eng 50:1347–1354

Li M, Li AL, Zhang JX, Huang YL, Li JM (2020a) Effects of particle sizes on compressive deformation and particle breakage of gangue used for coal mine goaf backfill. Powder Technol 360:493–502

Li W, Huang YL, Gao HD, Li JM, Ruan ZY, Song TQ (2020b) Study on acoustic emission characteristics of guague of different graduations during confined compression. J Min Saf Eng 37:155–161+168

Li JM, Huang YL, Pu H, Gao HD, Li YS, Ouyang SY, Guo YC (2021) Influence of block shape on macroscopic deformation response and meso-fabric evolution of crushed gangue under the triaxial compression. Powder Technol 384:112–124

Li M, Zhang JX, Huang P, Wang JQ, Wang YY (2022a) Control factors stope roof subsidence in deep gangue backfill mining and its influence law. J Min Saf Eng 39:227–238

Li Y, Song L, Tang Y, Zuo J, Xue D (2022b) Evaluating the mechanical properties of anisotropic shale containing bedding and natural fractures with discrete element modeling. Int J Coal Sci Technol 9(1):18

Liu JG, Li XW, He T (2020) Application status and prospect of backfill mining in Chinese coal mines. J China Coal Soc 45:141–150

Ma ZG, Guo GL, Chen RH, Mao XB (2005) An experimental study on the compaction of water-saturated over-broken rock. Chin J Rock Mech Eng 24:1139–1144

Miu XX (2012) Progress of fully mechanized mining with solid backfilling technology. J China Coal Soc 37:1247–1255

Miu XX, Mao XB, Hu GW, Ma ZG (1997) Study on crushing swelling and compaction characteristics of rock (coal). J China Coal Soc 12:64–70

Mu H, Song D, He X, Li Z, Su D, Xue Y (2021) Regional local integrated rockburst monitoring and early warning for multi-seam mining. J Geophys Eng 18(5):725–739

National Energy Administration (2014) Method of compaction testing of solid backfilling materials. Energy industry standard, Beijing, NB/T 51019-2014

Oldecop LA, Alonso EE (2004) Testing rockfill under relative humidity control. Geotech Test J 27:269–278

Pappas DM, Mark C (1993) Behavior of simulated longwall gob material. Report of investigations, US Bureau of Mines

Przyłucka M, Kowalski Z, Perski Z (2022) Twenty years of coal mining-induced subsidence in the Upper Silesia in Poland identified using InSAR. Int J Coal Sci Technol 9(1):86

Qian MG, Shi PW, Xu JL (2010) Underground pressure and strata control. China University of Mining and Technology Pressure, Xuzhou

Ran H, Guo Y, Feng G, Qi T, Du X (2021) Creep properties and resistivity-ultrasonic-AE responses of cemented gangue backfill column under high-stress area. Int J Min Sci Technol 31:401–412

Sitharam TG, Vinod JS (2010) Evaluation of shear modulus and damping ratio of granular materials using discrete element approach. Geotech Geol Eng 28:591–601

Su CD, Gu M, Tang X, Guo WB (2012) Experiment study of compaction characteristics of crushed stones from coal seam roof. Chin J Rock Mech Eng 31:18–26

Sun C, Yan SH, Xu NZ, Yin XW, Tian GS (2020) Experimental study on the stiffness of waste rock of gob of fully mechanized mining with large mining height. J China Coal Soc 45:38–48

Wang ML (2013) Simulation of compression test on gangue by PFC3D. Chin J Rock Mech Eng 32(2013):1350–1357

Xu JM, Zhang JX, Huang YL, Ju F (2011) Experimental research on the compress deformation characteristic of waste-fly ash and its application in backfilling fully mechanized coal mining technology. J Min Safe Eng 28:158–162

Yan H, Zhang JX, Zhang S, Mei XC, Chen JL (2017) Macro-micro research on compaction properties of granular backfilling materials. J China Coal Soc 42:413–420

Yang K, Wei Z, Zhao XY, He X, Zhang JQ, Ji JS (2021) Theory and technology of green filling of solid waste in underground mine at coal power base of Yellow River Basin. J China Coal Soc 46:925–935

Yang K, Wei Z, He X, Zhou GH, Chen DH, Zhang JQ (2022) Simulation experiment on bearing mechanical properties of gangue aggregate. J China Coal Soc 47:1087–1097

Yu BY, Chen ZQ, Feng MM, Wu JY, Ding QL (2017) Microstructure evolution of saturated crushed limestone under lateral confined compression based on CT test. J China Coal Soc 42:367–372

Zhang ZD, Li GY (2017) Experimental study on particle breakage behaviors of rockfill under cyclic loadings. Chin J Geotech Eng 39:1510–1516

Zhang JX, Li M, Liu Z, Zhou N (2017) Fractal characteristics of crushed particles of coal gangue under compaction. Powder Technol 305:12–18

Zhang JW, Wang HL, Chen SJ, Li YL (2018) Bearing deformation characteristics of large-size broken rock. J China Coal Soc 43:1000–1007

Zhang C, Tu SH, Zhao YX (2019) Compaction characteristics of the caving zone in a longwall goaf: a review. Environ Earth Sci 78:1–20

Zhang C, Zhao YX, Tu SH, Hao XJ, Hao DY (2020) Influence mechanism of particle size on the compaction and breakage characteristics of broken coal mass in goaf. J China Coal Soc 45:660–670

Zhang C, Zhao YX, Bai QS (2022a) 3D DEM method for compaction and breakage characteristics simulation of broken rock mass in goaf. Acta Geotech 17:2765–2781

Zhang C, Li B, Song Z, Liu J, Zhou J (2022b) Breakage mechanism and pore evolution characteristics of gangue materials under compression. Acta Geotech 17:4823–4835

Zhou N, Han XL, Zhang JX, Li M (2016) Compressive deformation and energy dissipation of crushed coal gangue. Powder Technol 297:220–228

Acknowledgements

Financial support for this work was provided by the Natural Science Research Project of Anhui Educational Committee (No. 2022AH050839), the National Natural Science Foundation of China (52104155, 52130402), the Scientific Research Foundation for High-level Talents of Anhui University of Science and Technology (2021yjrc11) and the Open Research Grant of Joint National-Local Engineering Research Centre for Safe and Precise Coal Mining (Grant NO. EC2022012).

Funding

Natural Science Research Project of Anhui Educational Committee (2022AH050839); National Natural Science Foundation of China (52104155, 52130402); Scientific Research Foundation for High-level Talents of Anhui University of Science and Technology (2021yjrc11).

Author information

Authors and Affiliations

Contributions

X.H. and C.Z. performed the parameter design, participated in the test, and drafted the manuscript. K.Y., Z.W., B.L. and S.H. conducted the field measurement and conceived of, designed, and coordinated the study.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, X., He, S., Yang, K. et al. Compaction characteristics and energy dissipation of crushed gangue with different particle sizes under mining stress. Environ Earth Sci 82, 310 (2023). https://doi.org/10.1007/s12665-023-11011-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-023-11011-0