Abstract

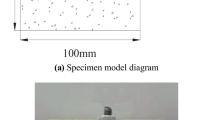

Joint properties play a controlling role in the strength of rock mass. In response to the situation that existing researches on bolting mechanism of bolted rock joints principally concentrate on the macroelements, such as rock properties, bolting angle and joint morphology, the direct shear tests on unbolted and single-bolted rock joints under the conditions of different normal stress and different joint microproperties by numerical calculation method of particle flow (PFC) were carried out in this paper to reveal the microbolting mechanism and study the influences of joint properties. Subsequently, a comprehensive comparison of microfailure characteristics between unbolted and single-bolted rock joint demonstrated that during the shearing process, a triangle extrusion reinforcement area emerges around the bolt, where microcracks are extremely developed and rock blocks are considerably fractured, but it also improves the anti-shearing efficacy of rock joint. Meanwhile, both the macroshear behavior and microfailure characteristics of single-bolted rock joints with different joint microproperties was analyzed by comparing the shear stress–shear displacement curves and crack development. Specifically, the shear stiffness of single-bolted rock joints enhances with the increase of joint tangential stiffness, and the augmentation of joint tangential stiffness or friction coefficient intensifies the shearing resistance of single-bolted rock joints, whereas the joint normal stiffness was proven to share a negative correlation with the shear strength of single-bolted rock joints. Besides, the shear stiffness of single-bolted rock joints decreases approximately linearly with the increasing joint thickness. In addition, the thicker the joint, the lower the peak shear stress of single-bolted rock joints. With the increase of joint thickness, the crack number of single-bolted rock joint failure decreases, and the particle confinement of bolt is enhanced.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

Abbreviations

- τ :

-

Shear stress, MPa

- u :

-

Shear displacement, mm

- σ :

-

Compressive stress, MPa

- ε :

-

Compressive strain

- UCS:

-

Uniaxial compressive strength, MPa

- c :

-

Rock cohesion, MPa

- φ :

-

Rock internal friction angle, °

- E :

-

Elasticity modulus, MPa

- Sj_kn:

-

Joint normal stiffness, GPa

- Sj_ks:

-

Joint tangential stiffness, GPa

- Sj_μ :

-

Joint friction coefficient

- Sj_d w :

-

Joint thickness, mm

- σ n :

-

Normal stress, MPa

- τ p :

-

Peak shear stress, MPa

- τ s :

-

Shear stiffness, MPa/m

References

Akram MS, Ahmed L, Ullah MF, Rehman F, Ali M (2018) Numerical verification of empirically designed support for a headrace tunnel. Civ Eng J 4:2575. https://doi.org/10.28991/cej-03091182

Aziz N, Hossein J, Hadi MSN (2004) The effect of rock strength on shear behavior of fully grouted bolts. In: Proceedings fifth international symposium on ground support in mining and underground construction perth, pp 243−251

Bednarik RG (2019) Rock metamorphosis by kinetic energy. Emerg Sci J 3:293–302. https://doi.org/10.28991/esj-2019-01192

Bjurstrom S (1974) Shear strength of hard rock joints reinforced by grouted un-tensioned bolts. In: Proceedings of the 3rd international congress on rock mechanics, vol 1974, pp 1194–1199

Chen Y (2014) Experimental study and stress analysis of rock anchorage performance. J Rock Mech Geotech Eng 6:428–437. https://doi.org/10.1016/j.jrmge.2014.06.002

Chen Y, Lin H, Ding X, Xie S (2021) Scale effect of shear mechanical properties of non-penetrating horizontal rock-like joints. Environ Earth Sci 80:192. https://doi.org/10.1007/s12665-021-09485-x

Cho N, Martin CD, Sego DC (2008) Development of a shear zone in brittle rock subjected to direct shear. Int J Rock Mech Min Sci 45:1335–1346. https://doi.org/10.1016/j.ijrmms.2008.01.019

Cundall P (2000) Numerical experiments on rough joints in shear using a bonded particle model. Asp Tecton Faulting. https://doi.org/10.1007/978-3-642-59617-9_1

Das R, Singh TN (2020) Effect of rock bolt support mechanism on tunnel deformation in jointed rockmass: a numerical approach. Undergr Space 6:409–420

Du S-G, Lin H, Yong R, Liu G-J (2022) Characterization of joint roughness heterogeneity and its application in representative sample investigations. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-022-02837-4

Fan X, Li K, Lai H (2018) Experimental and numerical study of the failure behavior of intermittent rock joints subjected to direct shear load. Adv Civ Eng 4294501:1–19. https://doi.org/10.1155/2018/4294501

Fan X, Jiang X, Liu Y, Lin H, Li K, He Z (2021) Local stress distribution and evolution surrounding flaw and opening within rock block under uniaxial compression. Theor Appl Fract Mech. https://doi.org/10.1016/j.tafmec.2021.102914

Fan X, Yu H, Deng Z, He Z, Zhao Y (2022) Cracking and deformation of cuboidal sandstone with a single nonpenetrating flaw under uniaxial compression. Theor Appl Fract Mech 119:103284. https://doi.org/10.1016/j.tafmec.2022.103284

Farahmand K, Vazaios I, Diederichs MS, Vlachopoulos N (2018) Investigating the scale-dependency of the geometrical and mechanical properties of a moderately jointed rock using a synthetic rock mass (SRM) approach. Comput Geotech 95:162–179. https://doi.org/10.1016/j.compgeo.2017.10.002

Ferrero A (1995) The shear strength of reinforced rock joints. Int J Rock Mech Min Sci Geomech Abstr 32:590–600. https://doi.org/10.1016/0148-9062(95)00002-x

Ge XR, Liu JW (1988) Study of the shear resistance behaviour of bolted rock joints. Chin J Geotech Eng 10:8–19. https://doi.org/10.3321/j.issn:1000-4548.1988.01.002

He L, An XM, Zhao XB, Zhao ZY, Zhao J (2018) Development of a unified rock bolt model in discontinuous deformation analysis. Rock Mech Rock Eng 51:827–847

Jiang M, Liu J, Crosta G, Li T (2017) DEM analysis of the effect of joint geometry on the shear behavior of rocks. Comptes Rendus Mécanique 345:779–796. https://doi.org/10.1016/j.crme.2017.07.004

Ke B et al (2021) An experimental study on characteristics of impact compression of freeze-thawed granite samples under four different states considering moisture content and temperature difference. Environ Earth Sci 80:661. https://doi.org/10.1007/s12665-021-09952-5

Li K, Cheng Y, Yin ZY, Han DY, Meng JJ (2020) Size effects in a transversely isotropic rock under Brazilian tests: laboratory testing. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-020-02058-7

Lin H, Sun PH, Chen YF, Zhu YY, Fan X, Zhao YL (2020) Analytical and experimental analysis of the shear strength of bolted saw-tooth joints. Eur J Environ Civ Eng 24:1–15. https://doi.org/10.1080/19648189.2020.1726822

Liu Y, Dai F, Dong L, Xu N, Feng P (2018) Experimental investigation on the fatigue mechanical properties of intermittently jointed rock models under cyclic uniaxial compression with different loading parameters. Rock Mech Rock Eng 51:47–68. https://doi.org/10.1007/s00603-017-1327-7

Ma S, Zhao Z, Peng J, Gui Y (2018) Analytical modeling of shear behaviors of rockbolts perpendicular to joints. Constr Build Mater 175:286–295

Meng J, Zhang X, Huang J, Tang H, Mattsson H, Laue J (2020) A smoothed finite element method using second-order cone programming. Comput Geotech 123:103547. https://doi.org/10.1016/j.compgeo.2020.103547

Pellet F, Egger P (1996) Analytical model for the mechanical behavior of bolted rock joints subjected to shearing. Rock Mech Rock Eng 29:73–97. https://doi.org/10.1007/BF01079755

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364. https://doi.org/10.1016/j.ijrmms.2004.09.011

Song HW, Duan YY, Yang J (2010) Numerical simulation on bolted rock joints shearing performance. Min Sci Technol 20:460–465. https://doi.org/10.1016/S1674-5264(09)60226-X

Spang K, Egger P (1990) Action of fully-grouted bolts in jointed rock and factors of influence. Rock Mech Rock Eng 1990:201–229. https://doi.org/10.1007/bf01022954

Wang YP, Xiong LX (2020) Numerical analysis of the influence of bolt set on the shear resistance of jointed rock masses. Civ Eng J 6:1039–1055. https://doi.org/10.28991/cej-2020-03091527

Wang ZQ, Chen X, Xue X, Zhang L, Zhu WK (2019) Mechanical parameter inversion in sandstone diversion tunnel and stability analysis during operation period. Civ Eng J. https://doi.org/10.28991/cej-2019-03091382

Wen S, Zhang C, Zhang Y (2019) Favorable driving direction of double shield TBM in deep mixed rock strata: numerical investigations to reduce shield entrapment. Geomech Eng 17:237–245

Xie S, Lin H, Cheng C, Chen Y, Wang Y, Zhao Y, Yong W (2022) Shear strength model of joints based on Gaussian smoothing method and macro-micro roughness. Comput Geotech 143:104605. https://doi.org/10.1016/j.compgeo.2021.104605

Yang W, Zhang Q, Ranjith PG, Yu R, Luo G, Huang C, Wang G (2019) A damage mechanical model applied to analysis of mechanical properties of jointed rock masses. Tunn Undergr Space Technol 84:113–128. https://doi.org/10.1016/j.tust.2018.11.004

Yang H, Lin H, Chen Y, Wang Y, Zhao Y, Yong W, Gao F (2022) Influence of wing crack propagation on the failure process and strength of fractured specimens. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-021-02550-6

Yuan W, Li J, Li Z, Wang W, Sun X (2020a) A strength reduction method based on the Generalized Hoek-Brown (GHB) criterion for rock slope stability analysis. Comput Geotech 117:103240. https://doi.org/10.1016/j.compgeo.2019.103240

Yuan W, Li Z, Niu J, Li J (2020b) Research on a two-parameter reduction method that strictly satisfies the upper and lower limit theorem. Bull Eng Geol Environ 79:1–11. https://doi.org/10.1007/s10064-020-01736-8

Zhang K, Cao P, Ma GW, Wang WH, Fan WC, Li KH (2016) Strength, fragmentation and fractal properties of mixed flaws. Acta Geotech 11:901–912. https://doi.org/10.1007/s11440-015-0403-y

Zhang YZ, Wang G, Ma M, Zhao ZP, Zhao YP, Sun ZH (2017) Macro-micro study on failure mechanism of rock mass anchorage joints under different roughness. J Central South Univ (sci Technol) 48:3373–3383. https://doi.org/10.11817/j.issn.1672−7207.2017.12.031

Zhang C, Pu C, Cao R, Jiang T, Huang G (2019) The stability and roof-support optimization of roadways passing through unfavorable geological bodies using advanced detection and monitoring methods, among others, in the Sanmenxia Bauxite Mine in China’s Henan Province. Bull Eng Geol Environ 78:5087–5099. https://doi.org/10.1007/s10064-018-01439-1

Zhao Y, Zhang C, Wang Y, Lin H (2020) Shear-related roughness classification and strength model of natural rock joint based on fuzzy comprehensive evaluation. Int J Rock Mech Min Sci 128:104550. https://doi.org/10.1016/j.ijrmms.2020.104550

Acknowledgements

The anonymous reviewers are gratefully acknowledged for his valuable comments on the manuscript.

Funding

This paper gets its funding from project (51774322) supported by National Natural Science Foundation of China; Project (2018JJ2500) supported by Hunan Provincial Natural Science Foundation of China; Scientific research innovation project for graduate students of Central South University (2019zzts303). The authors wish to acknowledge these supports.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Lin, H., Xie, S. et al. Effect of joint microcharacteristics on macroshear behavior of single-bolted rock joints by the numerical modelling with PFC. Environ Earth Sci 81, 276 (2022). https://doi.org/10.1007/s12665-022-10411-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-022-10411-y