Abstract

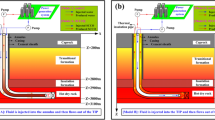

The prediction of the production capacity of the enhanced geothermal system (EGS) is crucial for the extraction of geothermal resources. To better optimize the EGS project, it is necessary to make a reasonable prediction of the heat-production capacity of the geothermal site. This work aims to provide an accurate and simpler calculation method based on geometric split-productivity superposition of multi-well EGS productivity prediction in large geothermal fields to guide the design and optimization of EGS in large geothermal fields. First, based on a complex potential function, a steady-state seepage model of well groups is established in a limited plane. After splitting the flow field according to the flow law in the plane, the productivity control area of a single injection well is obtained. The splitting method of the small well-group is obtained, which uses the bisector of the angle between the adjacent injection wells and the production well. Then, the three-dimensional finite-element numerical models of the EGS are established for the small well-group in the limited area and the single-pore double-well after splitting. By analyzing the heat production performance of the two methods, the correctness of the splitting method of the plane small well-group is verified. These models are based on the mathematical model of flow–heat coupling composed of the Dupuit formula, groundwater-flow equation, and porous-medium heat-transfer equation, combined with the split production-capacity-control area of the single injection well and the influence of the production well eccentricity. The comparison of the heat-production performances of the two methods shows that the maximum relative error rate of the two results does not exceed 9% and that the fluctuation trend of the corresponding double-well heat exchange EGS is consistent with the whole heat exchange EGS. These results prove that the splitting method has good applicability of predicting the EGS productivity of well groups in a limited area by calculating the superposition of the double-well EGS productivity after splitting. The total capacity of the well-group EGS in a limited area is equal to the sum of the capacity of each split double-well heat exchange EGS. Furthermore, this paper also provides proof of the rationality of the split method.

Similar content being viewed by others

References

Asai P, Panja P, Mclennan J, Moore J (2018) Performance evaluation of enhanced geothermal system (EGS): surrogate models, sensitivity study and ranking key parameters. Renew Energy 122:184–195. https://doi.org/10.1016/j.renene.2018.01.098

Bataillé A, Genthon P, Rabinowicz M, Fritz B (2006) Modeling the coupling between free and forced convection in a vertical permeable slot: implications for the heat production of an enhanced geothermal system. Geothermics 35(5):654–682. https://doi.org/10.1016/j.geothermics.2006.11.008

Beardsmore (2004) Thermal modelling of the hot dry rock geothermal resource beneath GEL99 in the Cooper Basin, South Australia. ASEG Ext Abstr 2004(1):1–4. https://doi.org/10.1071/aseg2004ab009

Bertani R (2012) Geothermal power generation in the world 2005–2010 update report. Geothermics 41:1–29. https://doi.org/10.1016/j.geothermics.2011.10.001

Bertani R (2016) Geothermal power generation in the world 2010–2014 update report. Geothermics 60:31–43. https://doi.org/10.1016/j.geothermics.2015.11.003

Cao W, Huang W, Jiang F (2016) A novel thermal-hydraulic-mechanical model for the enhanced geothermal system heat extraction. Int J Heat Mass Transf 100:661–671. https://doi.org/10.1016/j.ijheatmasstransfer.2016.04.078

Chen J, Jiang F (2013) A numerical study on heat extraction performance of enhanced geothermal systems. Renew Energy Resour 031(012):111–117, 121

Fangming J, Jiliang C (2015) Designing multi-well layout for enhanced geothermal system to better exploit hot dry rock geothermal energy. Renew Energy 1(74):37–48. https://doi.org/10.1016/j.renene.2014.07.056

Gee B, Gracie R, Dusseault MB (2021) Multiscale short-circuiting mechanisms in multiple fracture enhanced geothermal systems. Geothermics 94:102094. https://doi.org/10.1016/j.geothermics.2021.102094

Guo T, Tang S, Sun J, Gong F, Liu X, Qu Z et al (2020) A coupled thermal-hydraulic-mechanical modeling and evaluation of geothermal extraction in the enhanced geothermal system based on analytic hierarchy process and fuzzy comprehensive evaluation. Appl Energy 258:113981.1-113981.12. https://doi.org/10.1016/j.apenergy.2019.113981

He LW, Jin ZH (2010) A local thermal nonequilibrium poroelastic theory for fluid saturated porous media. J Therm Stress 33(8):799–813. https://doi.org/10.1080/01495739.2010.482358

Karsten P (2004) The TOUGH Codes—a family of simulation tools for multiphase flow and transport processes in permeable media. Vadose Zone J 3(3):738. https://doi.org/10.2136/vzj2004.0738

Lei H (2018) Assessment of geothermal reservoirs and enhanced geothermal system potential research in Wujiatun District, Northen Yitong Basin. Jilin University. https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CMFD201901&filename=1018073365.nh. Accessed 17 Oct 2021

Li J, Lei Z, Li S, Zhang R, Tang Z (2016) Optimizing water flood performance to improve injector efficiency in fractured low-permeability reservoirs using streamline simulation. In: SPE Kingdom of Saudi Arabia annual technical symposium and exhibition

Lu C, Wang G (2015) Current status and prospect of hot dry rock research. Sci Technol Rev 033(19):13–21. https://doi.org/10.3981/j.issn.1000-7857.2015.19.001

Mukuhira Y, Ito T, Asanuma H, Hring M (2020) Evaluation of flow paths during stimulation in an EGS reservoir using microseismic information. Geothermics. https://doi.org/10.1016/j.geothermics.2020.101843

Noorollahi Y, Itoi R (2011) Production capacity estimation by reservoir numerical simulation of northwest (NW) Sabalan geothermal field, Iran. Energy 36(7):4552–4569. https://doi.org/10.1016/j.energy.2011.03.046

Pruess K (2006) Enhanced geothermal systems (EGS) using CO_2 as working fluid—a novel approach for generating renewable energy with simultaneous sequestration of carbon. Geothermics 35(4):351–367. https://doi.org/10.1016/j.geothermics.2006.08.002

Pruess K (2008) On production behavior of enhanced geothermal systems with CO_2 as working fluid. Energy Convers Manag 49(6):1446–1454. https://doi.org/10.1016/j.enconman.2007.12.029

Qu ZQ, Zhang W, Guo TK (2017) Influence of different fracture morphology on heat mining performance of enhanced geothermal systems based on COMSOL. Int J Hydrog Energy 42(29):18263–18278. https://doi.org/10.1016/j.ijhydene.2017.04.168

Robert V, Ralph W, de Graaf L, Doone W (2007) Thermal modeling of long term circulation of multi-well development at the Cooper Basin hot fractured rock (HFR) project and current proposed scaled-up program. https://www.researchgate.net/publication/287493590. Accessed 17 Oct 2021

Saripally I (2015) CO2 flood optimisation using streamlines—a case study. Spe Middle East Oil Gas Show Conf. https://doi.org/10.2118/172810-MS

Sausse J, Dezayes C, Dorbath L, Genter A, Place J (2010) 3D model of fracture zones at Soultz-sous-Forêts based on geological data, image logs, induced microseismicity and vertical seismic profiles. C R Geosci 342(7–8):531–545. https://doi.org/10.1016/j.crte.2010.01.011

Song X, Yu S, Li G, Yang R, Lyu Z (2018) Numerical simulation of heat extraction performance in enhanced geothermal system with multilateral wells. Appl Energy 218:325–337. https://doi.org/10.1016/j.apenergy.2018.02.172

Xiangyan K (1999) Advanced mechanics of fluids in porous media (in Chinese). University of Science and Technology of China, Hefei, China, p 495. ISBN: 7-312-01052-0

Xu P, Zhang Q, Qian H, Li M, Hou K (2019a) Characterization of geothermal water in the piedmont region of Qinling Mountains and Lantian-Bahe Group in Guanzhong Basin, China. Environ Earth Sci. https://doi.org/10.1007/s12665-019-8418-6

Xu P, Li M, Qian H, Zhang Q, Liu F, Hou K (2019b) Hydrochemistry and geothermometry of geothermal water in the central Guanzhong Basin, China: a case study in Xi’an. Environ Earth Sci. https://doi.org/10.1007/s12665-019-8099-1

Yang SY, Yeh HD (2009) Modeling heat extraction from hot dry rock in a multi-well system. Appl Therm Eng 29(8–9):1676–1681. https://doi.org/10.1016/j.applthermaleng.2008.07.020

Yz A, Ng B, Cd A, Pj A (2020) Modeling study of deep direct use geothermal on the West Virginia university campus-morgantown, WV. Geothermics. https://doi.org/10.1016/j.geothermics.2020.101848

Zhang W, Qu Z, Guo T, Wang Z (2019) Study of the enhanced geothermal system (EGS) heat mining from variably fractured hot dry rock under thermal stress. Renew Energy 143A:855–871. https://doi.org/10.1016/j.renene.2019.05.054

Acknowledgements

This study was supported by Research Center of Geotechnical and Structural Engineering, Shandong University and Institute of Geothermal Development, Shandong University. And the completion of this article was inseparable from the contributions of all authors. In addition, Vikas Narang, the chief operating officer in Editage, was also very important for the English language polishing of this manuscript. Their support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, Y., Zhang, X., Zhang, Q. et al. Enhanced geothermal system productivity analysis of a well-group in a limited area based on the flow field split method. Environ Earth Sci 80, 718 (2021). https://doi.org/10.1007/s12665-021-10030-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-021-10030-z