Abstract

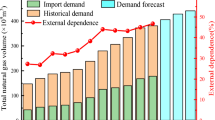

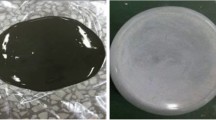

This study was conducted to find the optimal expansion for a new type of solidified expansive sealing (SES) material. The aim was to better meet the requirements for sealing gas extraction boreholes in underground coal mines by examining the expansion and creep properties of the material. The effect of different proportions of expansion agent on expansion time, expansion mechanisms, and creep properties of the SES material was investigated using an electronic universal testing machine and other systems. Based on the results of step loading creep tests, the Kelvin–Voigt viscoelastic model was selected to further analyze the mechanical properties of the material. The analysis showed that when the proportion of expansion agent in the SES is increased to 2.0%, the final expansion percentage increases to 11.5%, and the rapid expansion time and expansion preparation time quickly decreases to 18 and 12 min, respectively. In addition, the step loading displacement and constant force load displacement increase sharply. The creep parameters E0, E1, and η1 of the Kelvin–Voigt model reflect the gradually weakening of the compressive capacity and anti-deformation ability of the SES material. Based on the analysis of the experimental results and field application on sealing boreholes using SES material, it was possible to establish the optimum amount of expansion agent that should be added to the SES material. The optimized proportions can meet the requirements of good flowability, high compressive capacity, and anti-deformation ability for borehole sealing in a mine.

Similar content being viewed by others

References

Aguilera RF, Ripple RD, Aguilera R (2014) Link between endowments, economics and environment in conventional and unconventional gas reservoirs. Fuel 126:224–238

Akgun H, Daemen J (2000) Influence of degree of saturation on the borehole sealing performance of an expansive cement grout. Cem Concr Res 30(2):281–289

Akgün H (2010) Geotechnical characterization and performance assessment of bentonite/sand mixtures for underground waste repository sealing. Appl Clay Sci 49(4):394–399

Chen X, Cheng Y (2015) Influence of the injected water on gas outburst disasters in coal mine. Nat Hazards 76(2):1093–1109

Erol S, Francois B (2014) Efficiency of various grouting materials for borehole heat exchangers. Appl Therm Eng 70(1):788–799

Feyzullahoğlu E (2014) Abrasive wear, thermal and viscoelastic behaviors of rubber seal materials used in different working conditions. Proc Inst Mech Eng Part J J Eng Tribol 229(1):64–73

Fujimoto K, Ueda A, Ohtani T, Takahashi M, Ito H, Tanaka H, Boullier A (2007) Borehole water and hydrologic Nojima fault, SW model around the Japan. Tectonophysics 443(3–4):174–182

Funehag J, Fransson Å (2006) Sealing narrow fractures with a Newtonian fluid: model prediction for grouting verified by field study. Tunn Undergr Space Technol 21(5):492–498

Ge Z, Mei X, Lu Y, Tang J, Xia B (2015) Optimization and application of sealing material and sealing length for hydraulic fracturing borehole in underground coal mines. Arab J Geosci 8(6):3477–3490

Ghajari A, Kamali M, Mortazavi SA (2013) A comprehensive study of Laffan Shale Formation in Sirri oil fields, offshore Iran: implications for borehole stability. J Pet Sci Eng 107:50–56

Giannoukos K, Hall MR, Rochelle CA, Milodowski AE, Rigby SP (2014) Preliminary investigation on the chemical response of cementitious grouts used for borehole sealing of geologically stored CO2. Energy Procedia 59:174–181

Guo R, Dixon D (2006) Thermohydromechanical simulations of the natural cooling stage of the Tunnel Sealing Experiment. Eng Geol 85(3–4):313–331

Hashemi SS, Taheri A, Melkoumian N (2014) Shear failure analysis of a shallow depth unsupported borehole drilled through poorly cemented granular rock. Eng Geol 183:39–52

Imposima S, Vardoulakis I, Prisco CD (2000) Mechanical modelling of drained creep triaxial tests on loose sand. Géotechnique 50(1):73–82

Javadpour F, McClure M, Naraghi ME (2015) Slip-corrected liquid permeability and its effect on hydraulic fracturing and fluid loss in shale. Fuel 160:549–559

Jawed I, Skalny J (1978) Alkalies in cement: a review: II. Effects of alkalies on hydration and performance of Portland cement. Cem Concr Res 8(1):37–51

Kim C, Dixon D (2013) Evaluating hydro-mechanical interactions of adjacent clay-based sealing materials. Phys Chem Earth 65:98–110

Koenders EAB, Hansen W, Ukrainczyk N, Toledo Filho RD (2014) Modeling pore continuity and durability of cementitious sealing material. J Energy Resour ASME 136:0429044SI

Kurlenya MV, Serdyukov SV, Shilova TV, Patutin AV (2014a) Procedure and equipment for sealing coal bed methane drainage holes by barrier shielding. J Min Sci 50(5):994–1000

Kurlenya MV, Shilova TV, Serdyukov SV, Patutin AV (2014b) Sealing of coal bed methane drainage holes by barrier screening method. J Min Sci 50(4):814–818

Lade PV, Liu CT (1998) Experimental study of drained creep behavior of sand. J Eng Mech 124(8):912–920

Ma QY, Huang W, Cui PB (2011) Optimization study of expansive agents of shrinkage-compensating concrete. Adv Mater Res 250–253:750–754

Mitra A, Harpalani S, Liu S (2012) Laboratory measurement and modeling of coal permeability with continued methane production: part 1—laboratory results. Fuel 94:110–116

Moore TA (2012) Coalbed methane: a review. Int J Coal Geol 101:36–81

Paillet F (2004) Borehole flowmeter applications in irregular and large-diameter boreholes. J Appl Geophys 55(1–2):39–59

Pusch R (2011) A technique to delay hydration and maturation of borehole seals of expansive clay. Eng Geol 121(1–2):1–6

Qin L, Zhai C, Liu S, Xu J, Tang Z, Yu G (2016) Failure mechanism of coal after cryogenic freezing with cyclic liquid nitrogen and its influences on coalbed methane exploitation. Energy Fuel 30(10):8567–8578

Qin L, Zhai C, Liu S, Xu J, Yu G, Sun Y (2017a) Changes in the petrophysical properties of coal subjected to liquid nitrogen freeze-thaw—a nuclear magnetic resonance investigation. Fuel 194:102–114

Qin L, Zhai C, Liu S, Xu J (2017b) Factors controlling the mechanical properties degradation and permeability of coal subjected to liquid nitrogen freeze-thaw. Sci Rep 7(1):3675

Qin L, Zhai C, Liu S, Xu J (2018) Mechanical behavior and fracture spatial propagation of coal injected with liquid nitrogen under triaxial stress applied for coalbed methane recovery. Eng Geol 233:1–10

Stroes-Gascoyne S (2010) Microbial occurrence in bentonite-based buffer, backfill and sealing materials from large-scale experiments at AECL’s Underground Research Laboratory. Appl Clay Sci 47(1–2):36–42

Yan P, Wang Q, Feng J, Miao M (2012) The influence of high-temperature curing on the hydration characteristics of a cement—GGBS binder. Adv Cem Res 24(1):33–40

Zhai C, Xiang X, Xu J, Wu S (2016a) The characteristics and main influencing factors affecting coal and gas outbursts in Chinese Pingdingshan mining region. Nat Hazards 82(1):507–530

Zhai C, Qin L, Liu S, Xu J, Tang Z, Wu S (2016b) Pore structure in coal: pore evolution after cryogenic freezing with cyclic liquid nitrogen injection and its implication on coalbed methane extraction. Energy Fuel 30(7):6009–6020

Zhang C (2011) Experimental evidence for self-sealing of fractures in claystone. Phys Chem Earth Parts A/B/C 36(17–18):1972–1980

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (NSFC) under Grant numbers 51374168, 51774234, 51327007, and 51504189. We thank Ms. Yixin Zhang and David Frishman, PhD, for editing the English text of a draft of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, T., Bao, R., Li, S. et al. Expansion properties and creep tests for a new type of solidified expansive sealing material for gas drainage boreholes in underground mines. Environ Earth Sci 77, 468 (2018). https://doi.org/10.1007/s12665-018-7654-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-018-7654-5