Abstract

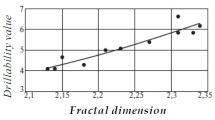

The microstructures of the drilling fluid changed while circulation due to the different shearing action from pipe or annular to bit water way in the drilling process of hydrate formation, which affects the performance of the drilling fluid and the stability of the wall. Since the dynamical microstructure of the drilling fluid is very complicated, the characteristics of the microstructure of a water-based polymer drilling fluid under the different shearing action (600 and 6000 r/min) were studied in this paper. According to the fractal theory, the fractal models of the microstructures of drilling fluid were established on the basis of the Sierpinski carpet model and Menger sponge model. The microstructure was analyzed quantitatively using the Image Pro Plus software. The results show that the microstructure is comprised of the skeleton structure formed by polymer and pores filled with small molecules such as inorganic salt ions and hydration molecule. The strong shearing action can change the shape of the skeleton structure. The microstructure of drilling fluid has the fractal features, and the fractal models can be described by the fractal model of original skeleton area (volume), the fractal model of area (volume) of pores, and the fractal model of number of pores. The larger the porosity of drilling fluid microstructure, the smaller the fractal dimension of space distribution of the skeleton structure, and the smaller the fractal dimension of number ~ size distribution of pores. The fractal dimension of the skeleton structure is equal to the fractal dimension of number ~ size distribution of pores on condition that ignoring the influence of r max. The fractal dimension is between 1 and 2 in the planar space. Finally, the process of heat transfer was analyzed in the microstructure of drilling fluid, and the fractal model of heat transfer was set up. All these will support a theoretical basis for establishing the models of mass and heat transfer of the decomposition of natural gas hydrates in the drilling fluid.

Similar content being viewed by others

References

Cai J, Huai XL (2010) Study on fluid–solid coupling heat transfer in fractal porous medium by lattice Boltzmann method. Appl Therm Eng 30:715–723

Fang YX, Jin XL, Li MB (2002) Exploration and development technology of natural gas hydrate (NGH). J China Offshore Platf 17(2):11–15 (in Chinese)

Feder J (1988) Fractals. Plenum Press, New York, pp 1–199

Han B, Zhang L, Jiang GS, Ning FL, Liu L, Fan Y et al (2012) Microstructure research of CMC solution at the different shearing action. Geol Sci Technol Inf 31(1):122–126 (in Chinese)

Han B, Zhang L, Wang T, Zhang XD, Yi XF, Liu XF (2013) An experimental study on microstructures of drilling fluid in hydrate formation under different shearing actions. Geol Explor 49(4):0760–0769 (in Chinese)

Harnson C, Park M, Chaikin PM et al (1998) Layer by layer imaging of diblock copolymer films with a scanning electron microscope. Polymer 39(13):2733–2745

Jahn W, Strey R (1988) Microstructure of microemulsions by freeze fracture electron microscopy. J Phys Chem 92:2294–2301

Jiang GS, Wang D, Tang FL, Ye JL, Zou HY, Ni XY et al (2002) Natural gas hydrates exploration and development. China University of Geosciences Press, Wuhan (in Chinese)

Katz AJ, Thompson AH (1985) Fractal sandstone pores: implications for conductivity and pore formation. Phys Rev Lett 54:1325–1328

Kozlov GV, Yanovskii YG (2014) Fractal mechanics of polymers: chemistry and physics of complex ploymeric materials. CRC Press, Baca Raton

Liu R, Jiang Y, Li B et al (2015) A fractal model for characterizing fluid flow in fractured rock masses based on randomly distributed rock fracture networks. Comput Geotech 65:45–55

Lyubenova TS, Matteucci F, Costa A et al (2009) Ceramic pigments with sphene structure obtained by both spray and freeze-drying techniques. Powder Technol 193(1):1–5

Mao H, Qiu ZS, Fu JG et al (2015) Synthesis and drilling fluid performance of polymer based nano-silica composite. J Centr South Univ Sci Technol 46(7):2564–2570

Max MD, Lowrie A (1996) Oceanic methane hydrate: a “frontier” gas resource. J Pet Geol 19(1):41–56

Moore CA, Donaldson CF (1995) Quantifying soil micorstructure using fractals. Geotechnique 1(45):105–116

Ning FL, Jiang GS, Zhang L, Wu X, Du B (2008) Analysis of key factors affecting wellbore stability in gas hydrate formations. Pet Drill Tech 36(3):59–61 (in Chinese)

Ono Y, Mayama H, Furo I, Sagidullin A, Matsushima K, Ura H, Uchiyama T, Tsujii K (2009) Characterization and structural investigation of fractal porous-silica over an extremely wide scale range of pore size. J Colloid Interface Sci 336:215–225

Pia G, Corcione CE, Striani R et al (2016) Thermal conductivity of porous stones treated with UV light-cured hybrid organic-inorganic methacrylic -based coating. Experimental and fractal modeling procedure. Prog Org Coat 94:105–115

Reimer I (1995) Scanning electron microscopy. Springer, New York, p 136

Shi MH, Chen YP (2001) The fractal theory of heat and mass transfer in porous material. J Nanjing Norm Univ Eng Technol 1(1):6–12 (in Chinese)

Shi MH, Fan K (2002) A fractal model for evaluating heat conduction in porous media. J Therm Sci Technol 1(1):28–31 (in Chinese)

Shou DH, Fan JT, Ding F (2010) A difference-fractal model for the permeability of fibrous porous media. Phys Lett A 374:1201–1204

Song YC, Yang L, Zhao JF, Liu WG, Yang MJ, Li YH et al (2014) The status of natural gas hydrate research in China: a review. Renew Sustain Energy Rev 31:778–791

Tao GL, Zhang JR (2009) Two categories of fractal models of rock and soil expressing volume and size-distribution of pores and grains. Chin Sci Bull 54(6):4458–4467 (in Chinese)

Turcotte DL (1986) Fractals and fragmentation. J Geophys Res 91(B2):1921–1926

Voss RF, Laibowitz RB, Allesandrini EI (1985) Fractal geometry of percolation in thin gold films. Scaling Phenom Disord Syst 133:279–288

Wen QB, Liang DC, Ren M et al (2008) Laboratory study on drilling fluid heat conductivity. Pet Drill Tech 36(1):30–32 (in Chinese)

Wu JS, Yu BM (2007) A fractal resistance model for flow through porous media. Int J Heat Mass Transf 50:3925–3932

Xiao BQ, Fan JT, Ding F (2012) Prediction of relative permeability of unsaturated porous media based on fractal theory and Monte Carlo simulation. Energy Fuels 26(11):6971–6978

Xu P (2011) Research on microstructures of hydrophobically associating water-soluble polymer solution and influence of surfactants on its rheological property. Southwest China Petroleum Institute, Nanchong (in Chinese)

Xu P, Yu B, Qiao X et al (2013) Radial permeability of unsaturated porous media by Monte Carlo simulations. Int J Heat Mass Transf 57(1):369–374

Yan JN (2001) Drilling fluid technology. China University of Petroleum Press, Dongying (in Chinese)

Yu BM (2008) Analysis of flow in fractal porous media. Appl Mech Rev 61:050801

Zhang JZ (1995) Fractal. Tsinghua University Press, Beijing (in Chinese)

Zhang LZ (2008) A fractal model for gas permeation through porous membranes. Int J Heat Mass Transf 51:5288–5295

Zhang DM, Xu TT, Niu YB (1995) Investigation on the microstructure of drilling fluid and filter cakes by cryogenic drying method. Drill Fluid Complet Fluid 12(3):1–7 (in Chinese)

Zhang L, Jiang G S, Ning F L, Han B, Wu X, Du B (2011) Discussion of the effect of drilling fluid on characteristics of heat and mass transfer of hydrate dissociation [C]. Mechanical society of China, Chongqing: Chongqing University Press, 2011: 206-207. (in Chinese)

Zhu HJ, Luo JH, Sui XG, Yao TM, Yang FH, Dai SJ et al (2006) Microstructure of novel polymer solution used for oil displacement. Acta Pet Sin 27(6):83–87 (in Chinese)

Acknowledgements

This work is granted by supported by the National Natural Science Foundation of China (Grant No. 41174061, 41374120) and Open Research Fund Program of Key Laboratory of Metallogenic Prediction of Nonferrous Metals and Geological Environment Monitoring (Central South University), Ministry of Education) (Grant No.2016YSJS002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, B., Lu, Gy., Cao, H. et al. Fractal features of the microstructure of the drilling fluid used into the hydrate-bearing sediments under the shearing action. Environ Earth Sci 76, 468 (2017). https://doi.org/10.1007/s12665-017-6798-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-017-6798-z