Abstract

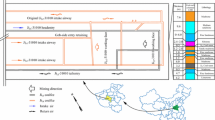

With the increasing demand for coal resources, coal mining has gradually entered into the deep strata of coal seams. Although the increase in mining depth improves energy security, it is associated with severe hazards, especially coal and gas outburst. Protective seam mining is an efficient method for gas control and has been widely used in major coal-producing countries. However, studies on deep ultra-thin protective seam (thickness 0.1–1 m, average thickness 0.5 m) mining and its related problems have been rarely reported. Focusing on the challenges resulting from deep mining (mining depth >1100 m) and the research gap, a coal and gas co-exploitation technique, which combines the gas control technology and green mining (including coal preparation and backfilling), has been proposed in this work. Significant benefits have been achieved in the twelfth coal mine of the Pingdingshan coalfield (study area) following the implementation of this technique. The application of the gas control technology markedly improved the gas drainage efficiency, promoted increased gas utilization, and reduced the greenhouse gas emission, providing notable economic and environmental benefits. In addition, implementation of green mining improved the coal quality, relieved the burden of the transport system, and, in particular, effectively prevented surface subsidence, thus protecting the ecological environment of the mining area, which offered significant economic, environmental, and social benefits. The practice in the twelfth coal mine could be used as a valuable example for coal mines with similar geological conditions.

Similar content being viewed by others

References

Aguado MBD, Nicieza CG (2007) Control and prevention of gas outbursts in coal mines, Riosa-Olloniego coalfield, Spain. Int J Coal Geol 69:253–266

Aziz N, Black D, Ren T (2011) Mine gas drainage and outburst control in Australian underground coal mines. Proc Eng 26:84–92

Bian ZF, Miao XX, Lei SG, Chen SE, Wang WF, Struthers S (2012) The challenges of reusing mining and mineral-processing wastes. Science 337:702–703

Bibler CJ, Marshall JS, Pilcher RC (1998) Status of worldwide coal mine methane emissions and use. Int J Coal Geol 35:283–310

Burchart-Korol D, Fugiel A, Czaplicka-Kolarz K, Turek M (2016) Model of environmental life cycle assessment for coal mining operations. Sci Total Environ 562:61–72

Chen SJ, Yin DW, Cao FW, Liu Y, Ren KQ (2016) An overview of integrated surface subsidence-reducing technology in mining areas of China. Nat Hazards 81:1129–1145

Dutta T, Kim KH, Uchimiya M (2016) Global demand for rare earth resources and strategies for green mining. Environ Res 150:182–190

Estrada JM, Bhamidimarri R (2016) A review of the issues and treatment options for wastewater from shale gas extraction by hydraulic fracturing. Fuel 182:292–303

Geng F, Saleh JH (2015) Challenging the emerging narrative: critical examination of coal mining safety in China and recommendations for tackling mining hazards. Saf Sci 75:36–48

Ghirian A, Fall M (2016) Strength evolution and deformation behaviour of cemented paste backfill at early ages: effect of curing stress, filling strategy and drainage. Int J Min Sci Technol. doi:10.1016/j.ijmst.2016.05.039

He MC, Xie HP, Peng SP, Jiang YD (2005) Study on rock mechanics in deep mining engineering. Chin J Rock Mech Eng 24:2803–2812

Hu SR, Peng JC, Huang C, Chen PK, Li M (2011) An overview of current status and progress in coal mining of the deep over a kilometer. China Min Mag 20:105–110

Hungerford F, Ren T, Aziz N (2013) Evolution and application of in-seam drilling for gas drainage. Int J Min Sci Technol 23:543–553

Jiang JY, Cheng YP, Zhang P et al (2015) CBM drainage engineering challenges and the technology of mining protective coal seam in the Dalong Mine, Tiefa Basin, China. J Nat Gas Sci Eng 24:412–424

Jin K, Cheng YP, Wang W et al (2016) Evaluation of the remote lower protective seam mining for coal mine gas control: a typical case study from the Zhuxianzhuang Coal Mine, Huaibei Coalfield, China. J Nat Gas Sci Eng 33:44–55

Karacan CÖ (2008) Modeling and prediction of ventilation methane emission of U.S. longwall mines using supervised artificial neural networks. Int J Coal Geol 73:371–387

Karacan CÖ, Ruiz FA, CotèM Phipps S (2011) Coal mine methane: a review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int J Coal Geol 86:121–156

Khaldoun A, Ouadif L, Baba K, Bahi L (2016) Valorization of mining waste and tailings through paste backfilling solution, Imiter operation, Morocco. Int J Min Sci Technol 26:511–516

Kong SL, Cheng YP, Ren T, Liu HY (2014) A sequential approach to control gas for the extraction of multi-gassy coal seams from traditional gas well drainage to mining-induced stress relief. Appl Energy 131:67–78

Lavrov A (2015) Flow of truncated power-law fluid between parallel walls for hydraulic fracturing applications. J Nonnewton Fluid Mech 223:141–146

Li W, Younger PL, Cheng YP et al (2015a) Addressing the CO2 emissions of the world’s largest coal producer and consumer: lessons from the Hasishiwan Coalfield, China. Energy 80:400–413

Li ZH, Wang EY, Ou JC, Liu ZT (2015b) Hazard evaluation of coal and gas outbursts in a coal-mine roadway based on logistic regression model. Int J Rock Mech Min Sci 80:185–195

Liu HB, Liu H, Cheng YP (2014) The elimination of coal and gas outburst disasters by ultrathin protective seam drilling combined with stress-relief gas drainage in Xinggong coalfield. J Nat Gas Sci Eng 21:837–844

Liu T, Lin BQ, Zou QL, Zhu CJ, Yan FZ (2016) Mechanical behaviors and failure processes of precracked specimens under uniaxial compression: a perspective from microscopic displacement patterns. Tectonophysics 672–673:104–120

Noack K (1998) Control of gas emissions in underground coal mines. Int J Coal Geol 35:57–82

Qian MG, Xu JL, Miao XX (2003) Green technique in coal mining. J China Univ Min Sci 32:343–348

Saleh JH, Cummings AM (2011) Safety in the mining industry and the unfinished legacy of mining accidents: safety levers and defense-in-depth for addressing mining hazards. Saf Sci 49:764–777

Sang SX, Xu HJ, Fang LC et al (2010) Stress relief coalbed methane drainage by surface vertical wells in China. Int J Coal Geol 82:196–203

Sobczyk J (2014) A comparison of the influence of adsorbed gases on gas stresses leading to coal and gas outburst. Fuel 115:288–294

State Administration of Coal Mine Safety (SACMS) (2016) Safety regulations for coal mine. China Coal Industry Publishing House, Beijing

Szlązak N, Obracaj D, Swolkień J (2014) Methane drainage from roof strata using an overlying drainage gallery. Int J Coal Geol 136:99–115

Toraño J, Torno S, Alvarez E, Riesgo P (2012) Application of outburst risk indices in the underground coal mines by sublevel caving. Int J Rock Mech Min Sci 50:94–101

Uszko M (2009) Monitoring of methane and rockburst hazards as a condition of safe coal exploitation in the mines of Kompania Węglowa SA. Proc Earth Planet Sci 1:54–59

Wang L, Cheng YP, An FH, Zhou HX, Kong SL, Wang W (2014a) Characteristics of gas disaster in the Huaibei coalfield and its control and development technologies. Nat Hazards 71:85–107

Wang L, Cheng LB, Cheng YP, Yin GZ, Xu C, Jin K, Yang QL (2014b) Characteristics and evolutions of gas dynamic disaster under igneous intrusions and its control technologies. J Nat Gas Sci Eng 18:164–174

Wang K, Jiang SG, Ma XP et al (2016) Abnormal gas emission in coal mines and a method for its dilution using ventilator control. J Nat Gas Sci Eng 33:355–366

Warmuzinski K (2008) Harnessing methane emissions from coal mining. Process Saf Environ Prot 86:315–320

Wei JP, Wang HL, Wang DK, Yao BH (2016) An improved model of gas flow in coal based on the effect of penetration and diffusion. J China Univ Min Technol 45(5):873–878

Wen ZJ, Qu GL, Wen JH, Shi YK, Jia CY (2014) Deformation failure characteristics of coal body and mining induced stress evolution law. Sci World J. doi:10.1155/2014/714507

Wen ZJ, Wang X, Tan YL, Zhang HL, Huang WP, Li QH (2016) A study of rockburst hazard evaluation method in coal mine. Shock Vibr. doi:10.1155/2016/8740868

Wen ZJ, Wang X, Chen LJ, Lin G, Zhang HL (2017) Size effect on acoustic emission characteristics of coal–rock damage evolution. Adv Mater Sci Eng. doi:10.1155/2017/3472485

Xue Y, Gao F, Gao YA et al (2016) Quantitative evaluation of stress-relief and permeability—increasing effects of overlying coal seams for coal mine methane drainage in Wulan coal mine. J Nat Gas Sci Eng 32:122–137

Yang GL, Yang RS, Tong Q, Huo C (2011a) Coalmine green mining with Gangue backfilling technique. Proc Environ Sci 10:1205–1209

Yang W, Lin BQ, Qu YA, Zhao S, Zhai C, Jia LL, Zhao WQ (2011b) Mechanism of strata deformation under protective seam and its application for relieved gas control. Int J Coal Geol 85:300–306

Yuan L (2016) Control of coal and gas outburst in Huainan mines in China: a review. J Rock Mech Geotech Eng 8:559–567

Yusuf RO, Noor ZZ, Abba A (2012) Methane emission by sectors: a comprehensive review of emission sources and mitigation methods. Renew Sustain Energy Rev 16:5059–5070

Zhang Q, Zhang JX, Kang T, Sun Q, Li WK (2015) Mining pressure monitoring and analysis in fully mechanized backfilling coal mining face—a case study in Zhai Zhen Coal Mine. J Central South Univ 22:1965–1972

Zhang Q, Zhang JX, Han XL, Ju F, Tai Y, Li M (2016) Theoretical research on mass ratio in solid backfill coal mining. Environ Earth Sci 75:586–596

Zhou FB, Sun YN, Li HJ, Yu GF (2016a) Research on the theoretical model and engineering technology of the coal seam gas drainage hole sealing. J China Univ Min Technol 45(3):433–439

Zhou FB, Xia TQ, Wang XX, Zhang YF, Sun YN, Liu JS (2016b) Recent developments in coal mine methane extraction and utilization in China: a review. J Nat Gas Sci Eng 31:437–458

Zou QL, Lin BQ, Zheng CS et al (2015) Novel integrated technique of drilling–slotting–separation–sealing for enhanced coal bed methane recovery in underground coal mine. J Nat Gas Sci Eng 26:960–973

Acknowledgements

This work was supported by the Graduate Students Innovation Engineering Foundation of Jiangsu Province (KYZZ16_0227); the State Key Research Development Program of China (Grant No. 2016YFC0801402); the National Natural Science Foundation of China (No. 51474211; 51404261); the Central Universities special Funds for Fundamental Research Funds of the China University of Mining and Technology (No. 2014ZDPY04); the Natural Science Foundation of Jiangsu Province (BK20140196). The authors also thank K Anand Kumar for editing this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, T., Lin, B., Yang, W. et al. An integrated technology for gas control and green mining in deep mines based on ultra-thin seam mining. Environ Earth Sci 76, 243 (2017). https://doi.org/10.1007/s12665-017-6567-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-017-6567-z