Abstract

The scope and extent of mine subsidence caused by exploitation of metal ores are usually low. However, in some cases, owing to such factors as special geological conditions in ore body, backward mining technology and unsound management systems, exploitation of metal ores would also lead to a large area of mine subsidence, causing great damages to the mining environment and infrastructure. A serious mine subsidence happened in January 2007 at the Haolaigou Iron Ore Mine has caused a huge collapse pit on the earth’s surfaces. This provides a suitable place to study the influence of mine subsidence. Based on former research results, a 3D geological model is constructed using the ROCK MODEL software developed by authors’ group. Based on in situ geological conditions, the range of orebody mining and the physical and mechanical parameters of rock and soil mass were determined by inverse analysis. Creep analysis of the collapse pit was also performed. Furthermore, the elastoplastic and creep of the secondary collapse were computed, and the final range of the collapse pit was predicted. Finally, the influences of mining subsidence on the ecological environment and public infrastructure are discussed and control measures were proposed. The results indicate that the collapse pit would not affect the road even if creep is considered; however, the secondary collapse would influence the road. So the collapse pit should be dealt with as soon as possible.

Similar content being viewed by others

Introduction

Mine subsidence, which is a widely occurring geological hazard as a result of the development of mineral resources, has been a hot research topic throughout the world (Booth et al. 1998; Bell et al. 2000; Bell et al. 2005; Yang 2001; Kong and Li 2006). There is no doubt that the situation of mine subsidence has becoming worser due to the scarcity of land resources, especially in China, where the disastrous consequences caused by mine subsidence are prominent. The main environmental disasters caused by mine subsidence have such forms as land subsidence, land fissures or water accumulation, agricultural reduction, road collapse, and deformation or damage of buildings.

Compared with coal, the geological conditions in metal ore mines are more complicated, and the development of mine subsidence is usually irregular; hence, little research on mine subsidence caused by exploitation of metal ores has been carried out (Diao et al. 2006). Traditionally, research on pattern and prediction of mine subsidence caused by exploitation of metal ores employs such approaches as ground leveling, numerical simulation, indoor physical model tests and experiences of engineering geologists (Li 2002; Diao et al. 2006). Recently, some new technology has been brought into this field. For example, the theory of random medium was used to forecast mine subsidence by Zhang and Liu (2004), and the theory of fractal was employed by Xie et al. (2003) to study mine subsidence.

Numerous disasters caused by mine subsidence in metal ore mines have been reported in China (Lin et al. 2004; Zhou and Zhang 2007; Chen et al. 2005; Zhu 1999; Wu 2005). On the midnight of 17 January 2007, a serious water bursting accident happened at block 1 of Haolaigou Iron Ore Mine, which is located in Baotou, Inner Mongolia, China. Although the authorities had tried their best to rescue, there were 29 deaths. The water bursting accident caused serious land subsidence, and made a great loss to the local economy. More than ten houses, one high voltage tower, two electricity poles, and 20,000 m2 of orchard were damaged, with a direct economic loss of about 600,000 US dollars. Some of the photos taken after the accident are shown in ESM Figs.1–3.

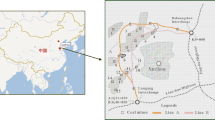

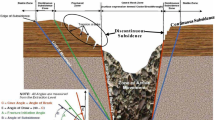

After investigations, experts had found out the causes of the accident. The roof bedrock of this collapse area ore body was very thin, even without bedrocks in some places. After exploitation of the ore body, the mined-out area was not filled as required, which resulted in the falling of the overlying thick Quaternary deposits into the mined-out area. Due to the Quaternary aquifer, a mixture of water, stone and clay entered the mined-out area, causing a big collapse pit in the surface, which was about 150 m in diameter, 30 m in depth, and 17,663 m2 in area. Moreover, there were many fissures in the area of about 80 m around the collapse pit, in the form of a ring with the collapse pit as its center. The fissures range in width from 2 to 20 cm and in length from 0.5 to 20 m. The edge of the collapse pit is about 60 m away from the north ring road of the city of Baotou, and there are many farmlands to the southwest of the collapse pit, as well as many high voltage towers, electricity poles and houses around the collapse pit. Some of the photos taken after the accident are shown in ESM Figs. 4, 5. The location of infrastructure is shown in Fig. 1.

Up to May 2007, the monitoring data show that the collapse pit is still deforming continuously. Considering the importance of the environment and facilities around the collapse pit, it is important and necessary to know whether the continuing deformation would affect the nearby roads, farmlands, electricity equipments and houses. If the collapse pit is not dealt with in time, whether a secondary collapse caused by rainstorms influence these important facilities? In this paper, based on detailed analysis of geological conditions and mining design information, in combination with field investigations, engineering analogy and numerical simulation are used simultaneously to analyze the status and developmental trends of mine subsidence. Finally, the influences of mining subsidence on the ecological environment and public infrastructure are evaluated synthetically.

Geological conditions

Haolaigou Iron Ore Mine is located in East village, East river district, Baotou, Inner Mongolia. The distance between Mining area and the Baotou urban is about 3.5 km; Hu-Bao highway passes through the northern mining area, and the Northern Ring Road through the western mining area, it very convenient to go in all directions. The traffic map is shown in ESM Fig. 5.

The study area is located in the west of Inner Mongolia Autonomous Region, in which a typical semi-arid and sub-humid temperate continental monsoon is prevalent, windy and drought in spring, mild in summer. The annual average temperature is 6.4°C, and the minimum temperature is −34.1°C, the maximum temperature 38.4°C. The rainfall is concentrated in the July–September, and the average precipitation for many years is about 322.3 mm.

The mining area is located in the border which is made by the southern slope of the DaQing mountain southern section and the Piedmont plain, in general, the hypsography is high in south and low in north The sea elevation is more than 1,200 m, the relative height difference is less than 20 m. There is the acclivitous Piedmont plain in south, and the terrain of mining area is hilly.

The mining district has a simple structure, which is a monoclinal structure with a strike of NW and a dip direction of SE. In the region of block 1, there is a fault, F1, which has an effect on mining. The fault F1 strikes nearly from east to west, dipping to the north at 35°to 70°, even at nearly 90° in some places. The amplitude of the fault is about 200 m and the width of the shattered fault zone is as long as 140 m.

The block 1 of the iron ore is mainly composed of pre-Sinian hypometamorphic rocks and Quaternary deposits. The hypometamorphic rocks belong to the fourth sub-group of the iron-bearing gneiss of the Archaean Sanggan group; the Quaternary deposits consist of yellow and yellow-brown alluvial–fluvial sand, gravel of the Pleistocene and Holocene Series. There are humic-soil and loess occurring on the ground, with a thickness ranging from 25 to 30 m.

The wall rock of the ore body belongs to mid-hard to hard rock, with a specific weight of 27 kN m−3, a uniaxial compressive strength of more than 90 MPa, and a Platts coefficient of 8–19. The ore body belongs to hard rock, with a specific weight of 34 kN m−3, a uniaxial compressive strength of more than 170 MPa, and a Platts coefficient of 17–19. However, due to the influence of fissures and the shattered fault zone, the intactness of the rock mass was reduced, resulting in the engineering geological conditions to be not good enough.

The inverse analysis on calculation parameters and the mining area

The exploitation method utilized in the Haolaigou Iron Ore Mine is short hole stopping with backfilling. According to the measured data and design data of more than 40 mines in China (Anonymous 1990), in combination with the terrain, landform, geological conditions, strength of wall rock, buried depth of the ore body and the exploitation method, the parameters of ground movement are determined as follows: the traveling angle of topsoil in the hanging wall is β soil = 35°, in the foot wall is δ soil = 45°, and in the boundary corners is γ soil = 45°; the traveling angle of rock in the hanging wall is β = 65°, in the foot wall is δ = 70°, and in the boundary corners is γ = 70°.

Based on geological data, the distribution area of block 1 of Haolaigou Iron Ore Mine has been determined, the depths of the four boundary corners A, B, C and D have been calculated to be 50, 44, 73 and 270 m, respectively (Fig. 1). According to the parameters of surface movement, if the ore body would had been totally exploited, the surface collapse area would be much larger than the current collapse area. This indicates that collapse happened as soon as the ore body was partly exploited. Furthermore, the rationality of mine subsidence prediction is dependent on appropriate mechanical parameters for the surrounding rock. During this research, first, a 3D geological model (ESM Figs. 6, Fig. 2) is constructed using the ROCK MODEL software developed by authors’ group (Xu et al. 2004a; Xu et al. 2004b). Based on the geological model, the study area is discretized into 321,195 cells, with 56,502 nodes (ESM Fig. 7). Second, based on the results of site investigations and exploitation design analysis, in combination with practical experience of disaster rescue, the location and extent of underground mined-out area are determined (Fig. 2). Finally, based on the actual collapse situation, FLAC 3D is employed for inverse analysis of strength parameters for the surrounding rock.

The parameters needed in the inverse analysis are derived from geological reports and design reports of the mine (Wu et al. 2005). The ideal elastoplastic model and the Moore–Coulomb failure criteria are chosen. The fault is considered to be a real unit. The final result of inverse analysis is shown in ESM Fig. 8. The maximum surface subsidence is calculated to be 28.827 m, and the diameter of the collapse pit is calculated to be 172.487 m, which is consistent with the real collapse scope and extent, and the parameters from inverse analysis are listed in Table 1.

Furthermore, the deformation of three cross-sections as shown in Fig. 1 was calculated and listed in Table 2. It can be seen that, the surface subsidence caused by the iron exploitation would never reach the road, but the big collapse deformation and horizontal tensile deformation would produce many sidestep-like fissures and horizontal tensile fissures. This is consistent with the in situ condition, as shown in ESM Figs 1 and 2.

Predicting the pattern of surface collapse

Creep analysis of surface collapse under current condition

The monitoring data obtained from simple equipments in May 2007 showed that the collapse pits were still deforming. If the collapse pits were not dealt with in time, how the collapse pits would develop under natural conditions is an important issue. In this study, based on the status of the collapse pit, creep analysis of the surface collapse was carried out by employing the Norton model. Considering the fact that the depth and extent of the collapse pit are very large and it is inevitable to deal with in time, only 1 year was taken into account. The standard form of the Norton model can be written as (Wu et al. 2005, 2006, 2007)

where \( \dot{\varepsilon }_{cr} \) is the creep rate, A and n are parameters for material behavior. The normal value of A is 1.0 × 10−25 P a−3*a−1, and n generally equals to 3.

The results are shown in Fig. 3. The maximum value of surface subsidence is 30.633 m in 1 year, which is 1.806 m greater than the initial collapse. As shown in Fig. 1, the extent of land collapse would increase greatly. Moreover, the high voltage towers, T4 and T1, the houses, H1 and H2, and parts of farmlands would be affected, but the high voltage towers, T2 and T3, the electricity pole, P1, and the ring road would not be affected.

Analysis of secondary collapse

If the current collapse pit was not dealt with in time, then under storm conditions, the collapsed material in the mined area would possibly be carried away by the scouring of infiltrated water, causing secondary collapse, which will bring even more serious consequences. The elastoplastic and creep analysis on the range of secondary collapse were conducted.

Results from elastoplastic analysis show that the maximum value of surface subsidence is 56.301 m, and the maximum collapse value at the road is 0.2 m. All infrastructure would be effected by mine subsidence expect for the high voltage tower, T3, near the edge of collapse. Results from creep analysis indicate that in 1 year the maximum value of surface subsidence would be as high as 57.572 m, and the maximum collapse value at the road would reach 0.45 m. All infrastructure would be affected by mine subsidence, and the collapse value at the high voltage tower, T3, would reach 0.25 m. The results are shown in Figs. 4, 5, 6, 7.

In addition, deformation on the aforementioned three sections was also computed, the results of which are shown in Tables 3 and 4. The maximum value of inclined strain is as high as 1,929.48 mm m−1, the maximum horizontal tensile strain in x direction reaches 191.167 mm m−1, and the maximum horizontal tensile strain in y direction is 807.253 mm m−1. It can be inferred that such a deformation would surely cause a step-like terrain and horizontal tensile fissures on the surface.

Suggested control measures

Based on the above results, if the secondary collapse happens, the safety of the road would be affected. Moreover, the average precipitation in the mining area is about 322.3 mm, and the amount of precipitation from July to September accounts for 70% of the total, so it is entirely possible that secondary collapse would happen as a result of rainfall. Therefore, the collapse pit needs to be dealt with as soon as possible by using the technique of filling. Detailed measures are proposed as follows.

The collapse pit

The volume of land subsidence pits caused by the 17th January water bursting accident was about 177,000 m3, the preferential filling materials are waste slag with a volume of 13,000 m3, and the other materials come from digging the soil and sand nearby. It is necessary to consider the slope after digging, which should be less than 10°. The surface soil should be taken out and preserved before filling and digging.

During the backfill, the pit’s bottom should be compacted first. Then backfill in layers, and each layer must be compacted. Finally, backfill the top layer using the original surface soil. The final height should be at least 20 cm higher than the local surface.

Land fissures

The total area of land fissures was about 55,000 km2. It was expected that soils with a volume of 1,000 m3 should be used to backfill the fissures. The final height should be at least 20 cm higher than the local surface.

Soil spot

After taking out the soil, the surface soil should be backfilled to the surface layer. In addition, it is indispensable to construct some large scale cut-off ditches and drains near the gullies in the study area before backfilling. Instead of the originally simple monitoring equipments, long-term systematic observation stations for land collapse should be established. Furthermore, emergency plans should be prepared.

Conclusions

-

1.

The numerical modeling results indicate that the maximum value of surface subsidence would increase 1.806 m in 1 year and the range of land collapse would increase greatly.

-

2.

The secondary collapse might happen under storm conditions. In this case, all infrastructure except for the high voltage tower, T3, would be affected in 1 year, and the road would not only collapse, but also generate many step-like terrains and horizontal tensile fissures. If creep is considered, the situation of collapse would be more serious, all of the infrastructure and the surrounding farmlands would be affected.

-

3.

Due to the natural and geological conditions of the mining area, especially the rainfall conditions, it is entirely possible that the secondary collapse would take place. The collapse pit should be dealt with as soon as possible by using the technique of backfilling.

-

4.

At present, the work has been finished and the effect is obviously good enough.

References

Anonymous (1990) Mining manual. Metallurgical Industry Press, Beijing

Bell FG, Stacey TR, Genske DD (2000) Mining subsidence and its effect on the environment: some differing examples. Env Geol 40:135–152

Bell FG, Donnelly LJ, Genske DD (2005) Unusual cases of mining subsidence from Great Britain, Germany and Colombia. Env Geol 47:620–631

Booth CJ, Spande ED, Pattee CT (1998) Positive and negative impacts of longwall mine subsidence on a sandstone aquifer. Env Geol 34:223–233

Chen HZ, Zhao JA, Wang ZL (2005) Study on the sustainable development of the mineral resources in Laiwu City. Territ Nat Resour Study 2:84–85

Diao XH, Yuan Y, Zhang CX (2006) Geological disasters of metal mines and trend in their research. Metal Ming 6:1–4

Kong GH, Li FP (2006) Research on environmental protection and control in mining sinking region. Hebei Coal 1:4–6

Li SL (2002) Study on the geological hazard in metal mines and its prevention countermeasures. Chin J Geol Hazard Control 13:44–48

Lin HP, Pan AD, Wang YL, Luo L (2004) Geological disasters in Guangdong Province and their prevention and control. J Nat Disasters 13:200–204

Wu DM (2005) Surface subsidence law and comprehensive control of Xinqiao ore deposit. China Mine Eng 34:15–17

Wu X, Jia ZX, Chen ZY, Wang XG, Yang J (2005) Research of a synthetical method—GMEM on ascertaining shear strength for engineering rock mass. Chin J Rock Mech Eng 24:246–251

Wu X, Yu QC, Wang XG, Duan QW, Li XQ, Yang J, Bao YF (2006) Exploitation of coal resources under surface water body. Chin J Rock Mech Eng 25:1029–1036

Wu X, Wang XG, Duan QW, Jia ZX, Xu NX, Sun YD (2007) Study on safety impact assessment and reinforcement measures of coal mining under important hydraulic engineering. Chin J Rock Mech Eng 26:338–346

Xie HP, Gao F, Zhou HW, Zuo JP (2003) Fractal fracture and fragmentation in rocks. J Disaster Prev Mitig Eng 23:1–9

Xu NX, He MC, Jing HH (2004a) 3D visual modeling technique of non-continuous non-folded rock-mass and its application. Chin J Rock Mech Eng 23:2534–2538

Xu NX, He MC, Jing HH (2004b) A study on 3D modeling techniques and visual system of rock mass structure. Chin J Geotech Eng 26:373–377

Yang L (2001) The mining subsidence destroys the environment of mine areas more seriously than earthquake. Sci Technol Rev 9:53–54

Zhang JS, Liu BC (2004) Determination of basic parameters in stochastic method by back analysis. J Xiangtan Min Inst 19:5–8

Zhou YZ, ZhangYJ (2007) The mechanism and control measures of the main geological hazards in northern part of Shangdong Province. Transactions of Oceanology and Limnology (Supp):60–68

Zhu JQ (1999) Primary analysis on geological hazard in the eastern area of Chenchao iron mine. Chin J Rock Mech Eng 18:497–502

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, X., Jiang, XW., Chen, YF. et al. The influences of mining subsidence on the ecological environment and public infrastructure: a case study at the Haolaigou Iron Ore Mine in Baotou, China. Environ Earth Sci 59, 803–810 (2009). https://doi.org/10.1007/s12665-009-0076-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12665-009-0076-7