Abstract

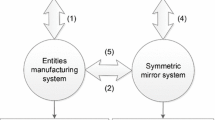

The multi-layer indices decision-making of complex industrial processes is the key to reducing costs and improving production efficiency. With the development of the Industrial Internet, a large number of industrial streaming data and intelligent algorithms have brought opportunities for optimizing plant-wide production indices. However, due to the strong dynamic and coupling of the production process, the intelligent system based only on the optimization algorithm cannot give practical data analysis suggestions and decision results, so a human–computer interactive visual analysis and index decision system are urgently needed. This paper combines multi-layer indices decision-making algorithms with 3D digital twin visual analysis technology to propose an intelligent decision-making system for mineral processing production indices based on 3D digital twin interactive visualization (DTIV). The DTIV system provides users a 3D digital twin modeling view from the production park, workshop, and equipment scenes. It adopts visualization technology that seamlessly integrates 3D and 2D to help users obtain indices decision input information and hidden data features from real-time stream data with different spatiotemporal data characteristics. In addition, the DTIV system also combines a multi-layer indices optimization decision-making algorithms engine and designs a human–machine interaction indices decision interface and indices decision execution visual analysis interface to improve users’ production perception and decision-making ability. Through our collaboration with domain experts, carefully designed interviews, and prototype system evaluation in a beneficiation plant, the effectiveness and usability of the system have been proven.

Graphic Abstract

Similar content being viewed by others

References

Bougouffa S, Vogel-Heuser B, Fischer J et al (2019) Visualization of variability analysis of control software from industrial automation systems. In: 2019 IEEE international conference on systems, man and cybernetics (SMC), pp 3357–3364. https://doi.org/10.1109/SMC.2019.8914367

Chai T (2009) Optimal operation and feedback control for complex industrial process. In: International conference on networking

Chai T, Zhang J, Yang T (2021) Demand forecasting of the fused magnesia smelting process with system identification and deep learning. IEEE Transactions on Industrial Informatics PP(99):1

Ding J, Yang C, Chai T (2017) Recent progress on data-based optimization for mineral processing plants. Engineering 3(2):183–187. https://doi.org/10.1016/J.ENG.2017.02.015

Fan Y, Yao W (2023) Research on 3d visualization logistics intelligent scheduling system based on digital twin. In: 2023 IEEE 2nd international conference on electrical engineering, big data and algorithms (EEBDA), pp 431–435. https://doi.org/10.1109/EEBDA56825.2023.10090776

Gao L, Xiao Q, Liu C et al (2016) Beneficiation production index optimization decision system based on intelligent mobile terminal and cloud computing. Comput Integr Manuf Syst 22(7):1821–1829. https://doi.org/10.13196/j.cims.2016.07.021

Gou X, Zhang Y, Hu Z et al (2023) A sketch framework for approximate data stream processing in sliding windows. IEEE Trans Knowl Data Eng 35(5):4411–4424. https://doi.org/10.1109/TKDE.2022.3151140

Guo L, Cheng Y, Zhang Y et al (2021) Development of cloud-edge collaborative digital twin system for FDM additive manufacturing. In: 2021 IEEE 19th international conference on industrial informatics (INDIN), pp 1–6. https://doi.org/10.1109/INDIN45523.2021.9557492

Heilala J, Montonen J, Järvinen P et al (2010) Developing simulation-based decision support systems for customer-driven manufacturing operation planning. In: Proceedings of the 2010 winter simulation conference, pp 3363–3375. https://doi.org/10.1109/WSC.2010.5679027

Henning K (2013) Recommendations for implementing the strategic initiative industrie 4.0

Hodouin D, Jämsa-Jounela S, Carvalho MT et al (2000) State of the art and challenges in mineral processing control. IFAC Proceedings Volumes

Jo J, Huh J, Park J et al (2014) LiveGantt: interactively visualizing a large manufacturing schedule. IEEE Trans Visual Comput Graphics 20(12):2329–2338. https://doi.org/10.1109/TVCG.2014.2346454

Joglekar A, Bhandari G, Sundaresan R (2022) An open simulator framework for 3d visualization of digital twins. In: 2022 IEEE international conference on internet of things and intelligence systems (IoTaIS), pp 278–284. https://doi.org/10.1109/IoTaIS56727.2022.9975980

Kimani S, Leva M, Mecella M et al (2013) Visualization of multidimensional sensor data in industrial engineering. In: 2013 17th international conference on information visualisation, pp 156–161. https://doi.org/10.1109/IV.2013.19

Lee A, Kim J, Jang I (2020) Movable dynamic data detection and visualization for digital twin city. In: 2020 IEEE international conference on consumer electronics—Asia (ICCE-Asia), pp 1–2. https://doi.org/10.1109/ICCE-Asia49877.2020.9277250

Li J, Yuan L, Ding J (2023) Asynchronous updating reinforcement learning algorithm for decision-making operational indices of uncertain industrial processes. Acta Autom Sin 49(2):461–472. https://doi.org/10.16383/j.aas.c210983

Li X, Gu X, Wang J et al (2023) Design and realization of steel plate yard digital management system based on industrial cloud. Mar Technol 51(1):80–87. https://doi.org/10.12225/j.issn.1000-3878.2023.01.20230115

Luo F, Ranzi G, Dong Z (2017) Rolling horizon optimization for real-time operation of thermostatically controlled load aggregator. J Modern Power Syst Clean Energy 5(6):947–958. https://doi.org/10.1007/s40565-017-0329-5

Ma E, Chai T, Bai R (2006) The optimization methods based on non-dominated sorting genetic algorithm for scheduling of material flow in mineral process. In: The Proceedings of the multiconference on “computational engineering in systems applications”, pp 2039–2044. https://doi.org/10.1109/CESA.2006.4281974

Ma MD, Wong DSH, Jang SS et al (2010) Fault detection based on statistical multivariate analysis and microarray visualization. IEEE Trans Ind Inf 6(1):18–24. https://doi.org/10.1109/TII.2009.2030793

Mihai S, Yaqoob M, Hung DV et al (2022) Digital twins: a survey on enabling technologies, challenges, trends and future prospects. IEEE Commun Surv Tutorials 24(4):2255–2291. https://doi.org/10.1109/COMST.2022.3208773

Mikhailov A, Tretyakov S, Andreev Y (2022) A new approach to build industrial internet of things (IIoT) Systems Based on digital twin’s technologies. In: 2022 International conference on industrial engineering, applications and manufacturing (ICIEAM), pp 1091–1095. https://doi.org/10.1109/ICIEAM54945.2022.9787171

Muskan, Singh G, Singh J et al (2022) Data visualization and its key fundamentals: A comprehensive survey. In: 2022 7th international conference on communication and electronics systems (ICCES), pp 1710–1714. https://doi.org/10.1109/ICCES54183.2022.9835803

Oguz, Aran, Yilmaz, et al (2006) Production and visualization of 3d city models from building allocation plans. In: 2006 IEEE 14th signal processing and communications applications, pp 1–4. https://doi.org/10.1109/SIU.2006.1659911

Pajpach M, Drahoš P, Pribiš R et al (2022) Educational-development workplace for digital twins using the OPC UA and unity 3D. In: 2022 Cybernetics & Informatics (K &I), pp 1–6. https://doi.org/10.1109/KI55792.2022.9925933

Ramanujan D, Bernstein WZ, Chandrasegaran SK et al (2017) Visual analytics tools for sustainable lifecycle design: current status, challenges, and future opportunities. J Mech Des 11:139

Sun D, Huang R, Chen Y et al (2019) PlanningVis: a visual analytics approach to production planning in smart factories. arXiv:1907.12201

Sun D, Huang R, Chen Y et al (2020) PlanningVis: a visual analytics approach to production planning in smart factories. IEEE Trans Visual Comput Graphics 26(1):579–589. https://doi.org/10.1109/TVCG.2019.2934275

Wei L (2022) Research on digital twin city platform based on unreal engine. In: 2022 International conference on information processing and network provisioning (ICIPNP), pp 142–146. https://doi.org/10.1109/ICIPNP57450.2022.00038

Weihua Y, Dong X (2021) Visual analysis of industrial knowledge graph research based on Citespace. In: 2021 7th international conference on condition monitoring of machinery in non-stationary operations (CMMNO), pp 297–300. https://doi.org/10.1109/CMMNO53328.2021.9467534

Wu W, Zheng Y, Chen K et al (2018) A visual analytics approach for equipment condition monitoring in smart factories of process industry. In: IEEE PacificVis 2018

Xu Q, Zhang K, Li M et al (2021) Multi-objective robust optimization for planning of mineral processing under uncertainty. In: 2021 33rd Chinese control and decision conference (CCDC), IEEE, pp 4020–4027

Yan X, Wan W, Zhang J (2013) Transportation simulation in 3D virtual city based on UC-win/Road. In: IET international conference on smart and sustainable city 2013 (ICSSC 2013), pp 461–465. https://doi.org/10.1049/cp.2013.1995

Yang C, Ding J, Jin Y et al (2019) Multitasking multiobjective evolutionary operational indices optimization of beneficiation processes. IEEE Trans Autom Sci Eng 16(3):1046–1057. https://doi.org/10.1109/TASE.2018.2865593

Yang Y, Wang D, Ding J (2022) Ragan based feedforward-feedback multi-step correction of operational indices for industrial processes. Acta Autom Sin. https://doi.org/10.16383/j.aas.c210408

Yu G, Chai T, Luo X (2011) Multiobjective production planning optimization using hybrid evolutionary algorithms for mineral processing. IEEE Trans Evol Comput 15:487–514

Yu G, Chai T, Luo X (2013) Two-level production plan decomposition based on a hybrid MOEA for mineral processing. IEEE Trans Autom Sci Eng 10(4):1050–1071. https://doi.org/10.1109/TASE.2012.2221458

Zhang P (1996) Visualizing production planning data. IEEE Comput Graph Appl 16(5):7–10. https://doi.org/10.1109/38.536268

Zhong Y, Marteau B, Hornback A et al (2022) IDTVR: a novel cloud framework for an interactive digital twin in virtual reality. In: 2022 IEEE 2nd International Conference on Intelligent Reality (ICIR), pp 21–26. https://doi.org/10.1109/ICIR55739.2022.00020

Acknowledgements

The authors thank Siming Chen (Fudan University) for guiding the paper’s writing. This work was supported by the Major Program of the National Natural Science Foundation of China (No.61991404) and research on key technologies and platform of process index decision-making and control integration for process industry of the Fundamental Research Funds for the Central Universities (N2324003-05), Key Technologies Research and Development Program of Guangzhou Municipality (Grant No.2022YFB3304704).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, K., Xu, Q., Liu, C. et al. Intelligent decision-making system for mineral processing production indices based on digital twin interactive visualization. J Vis (2024). https://doi.org/10.1007/s12650-024-00964-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12650-024-00964-4