Abstract

Purpose

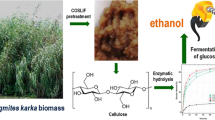

Biomass pretreatment followed by enzymatic hydrolysis is one of the most viable ways to obtain sugars from biomass. In this work, the effect combined alkaline pretreatment and Deep Eutectic Solvent on enzyme hydrolysis of Hyparrhenia filipendula by cellulase is investigated. There is no previously reported literature on this substrate and the authors aim to establish baseline values for further research in the utilization of Hyparrhenia filipendula.

Methods

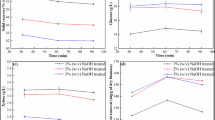

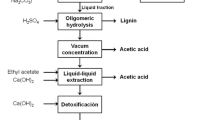

The yellow thatching grass (Hyparrhenia filipendula) was fractionated with a combination of alkaline and Deep Eutectic Solvent to increase sugar recovery. An alkaline solution of 10 wt % (w/v) of Sodium Hydroxide (NaOH) was used for the first stage of pretreatment at 100 °C for 4 h. Three DES, namely, Choline chloride (ChCl): urea; ChCl: glycerol; and Ethylene glycol: Citric acid at 1:2 molar ratio each, were heated to 80 °C until a clear solution was formed. The DESs were used for the second stage of pretreatment at 110 °C for 6 h in a Parr reactor. During the pretreatment, a solid: solvent ratio of 1:10 was used for the first and second stages of pre-treatment. Enzymatic hydrolysis was accomplished with a cellulase enzyme blend, Cellic CTec2, in a 50 mM sodium citrate buffer (pH 4.8) at 50 °C using a shaking incubator at a speed of 150 rpm. A solid loading of 2% and enzyme dosage of 50 g/100 g cellulose in the sample was used for all the experiments. Furthermore, samples were withdrawn every 24 h for 7 days and analyzed for glucose and xylose using High-Performance Liquid Chromatography (HPLC).

Results

A high delignification of 90% and hemicellulose removal of 70% was achieved with a combination of Alkali and ChCl: Urea pretreatment. Subsequently, the highest glucose and xylose conversion of 90% and 92% were observed, respectively, with the same sample. Additionally, the highest glucose yield achieved was 25 gL−1 from the combined alkaline/ChCl: Glycerol treated sample after 120 h. Moreover, the highest xylose yield was 3 gL−1 from the raw sample, the NaOH- pulped sample, and the ChCl: Glycerol-treated sample.

Conclusion

The results from this study demonstrated that the solvents used for fractionating biomass have a significant effect on the sugar recovery during enzymatic hydrolysis. Also, the pretreatment with a combination of NaOH and DES of ChCl: Glycerol was the most effective for the recovery of glucose and total sugar. In conclusion, yellow thatching grass is a promising substrate for bio-refineries. However, the ideal conditions for enzyme hydrolysis should be investigated further to promote its utilization for value-added products.

Graphical Abstract

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the study are not publicly available due to Copyright regulations by Makerere University and University of Pretoria, but are available from the corresponding author on reasonable request.

References

Baksi, S., Ball, A.K., Sarkar, U., Banerjee, D., Wentzel, A., Preisig, H.A., Kuniyal, J.C., Birgen, C., Saha, S., Wittgens, B.: Efficacy of a novel sequential enzymatic hydrolysis of lignocellulosic biomass and inhibition characteristics of monosugars. Int. J. Biol. Macromol. 129, 634–644 (2019)

Kristensen, J.B., Felby, C., Jørgensen, H.: Yield-determining factors in high-solids enzymatic hydrolysis of lignocellulose. Biotechnol. Biofuels 2(1), 1–10 (2009)

Dos Santos, A.C., Ximenes, E., Kim, Y., Ladisch, M.R.: Lignin–enzyme interactions in the hydrolysis of lignocellulosic biomass. Trends Biotechnol. 37(5), 518–531 (2019)

Sun, S., Sun, S., Cao, X., Sun, R.: The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Biores. Technol. 199, 49–58 (2016)

Przybysz, K., Małachowska, E., Martyniak, D., Boruszewski, P., Kalinowska, H., Przybysz, P.J.E.: Production of sugar feedstocks for fermentation processes from selected fast growing grasses. Energies 12(16), 3129 (2019)

Scordia, D., Cosentino, S.L.: Perennial energy grasses: resilient crops in a changing European agriculture. Agriculture 9(8), 169 (2019)

Raud, M., Kikas, T.: Perennial grasses as a substrate for bioethanol production. Environ. Climate Technol. 24(2), 32–40 (2020)

Wongwatanapaiboon, J., Kangvansaichol, K., Burapatana, V., Inochanon, R., Winayanuwattikun, P., Yongvanich, T., Chulalaksananukul, W.: The potential of cellulosic ethanol production from grasses in Thailand. J. Biomed. Biotechnol. (2012). https://doi.org/10.1155/2012/303748

Mohapatra, S., Mishra, C., Behera, S.S., Thatoi, H.: Application of pretreatment, fermentation and molecular techniques for enhancing bioethanol production from grass biomass–A review. Renew. Sustain. Energy Rev. 78, 1007–1032 (2017)

Tshivhase, V.M., Njinga, R.L., Mathuthu, M., Dlamini, T.C.: Transfer rates of 238U and 232Th for E. globulus, A. mearnsii, H. filipendula and hazardous effects of the usage of medicinal plants from around gold mine dump Environs. Int. J. Environ. Res. Public Health 12(12), 15782–15793 (2015)

Zhang, P., Dong, S.-J., Ma, H.-H., Zhang, B.-X., Wang, Y.-F., Hu, X.-M.: Fractionation of corn stover into cellulose, hemicellulose and lignin using a series of ionic liquids. Ind. Crops Prod. 76, 688–696 (2015)

Amit, K., Nakachew, M., Yilkal, B., Mukesh, Y.J.R.J.C.E.: A review of factors affecting enzymatic hydrolysis of pretreated lignocellulosic biomass. Res. J. Chem. Environ. 22(7), 62–67 (2018)

Luo, X., Liu, J., Zheng, P., Li, M., Zhou, Y., Huang, L., Chen, L., Shuai, L.: Promoting enzymatic hydrolysis of lignocellulosic biomass by inexpensive soy protein. Biotechnol. Biofuels 12(1), 1–13 (2019)

Saadon, S.Z.A.H., Osman, N.B., Yusup, S.: Pretreatment of fiber-based biomass material for lignin extraction, in value-chain of biofuels, pp. 105–135. Elsevier, Amsterlands (2022)

Wagle, A., Angove, M.J., Mahara, A., Wagle, A., Mainali, B., Martins, M., Goldbeck, R., Paudel, S.R.: Multi-stage pre-treatment of lignocellulosic biomass for multi-product biorefinery: a review. Sustain. Energy Technol. Assess. (2022). https://doi.org/10.1016/j.seta.2021.101702

Nagarajan, K., Ramanujam, N., Sanjay, M., Siengchin, S., Surya Rajan, B., SathickBasha, K., Madhu, P., Raghav, G.: A comprehensive review on cellulose nanocrystals and cellulose nanofibers: pretreatment, preparation, and characterization. Polym. Compos. 42(4), 1588–1630 (2021)

Dhali, K., Ghasemlou, M., Daver, F., Cass, P., Adhikari, B.: A review of nanocellulose as a new material towards environmental sustainability. Sci. Total Environ. 775, 145871 (2021)

Zu, S., Li, W.-Z., Zhang, M., Li, Z., Wang, Z., Jameel, H., Chang, H.-M.: Pretreatment of corn stover for sugar production using dilute hydrochloric acid followed by lime. Biores. Technol. 152, 364–370 (2014)

Jung, W., Savithri, D., Sharma-Shivappa, R., Kolar, P.: Changes in lignin chemistry of switchgrass due to delignification by sodium hydroxide pretreatment. Energies 11(2), 376 (2018)

Obeng, A.K., Premjet, D., Premjet, S.: Combining autoclaving with mild alkaline solution as a pretreatment technique to enhance glucose recovery from the invasive weed Chloris barbata. Biomolecules 9(4), 120 (2019)

Liu, C., van der Heide, E., Wang, H., Li, B., Yu, G., Mu, X.: Alkaline twin-screw extrusion pretreatment for fermentable sugar production. Biotechnol. Biofuels 6(1), 1–11 (2013)

Wang, Z., Keshwani, D.R., Redding, A.P., J. J. J. B. t. Cheng,: Sodium hydroxide pretreatment and enzymatic hydrolysis of coastal Bermuda grass. Bioresour. technol. 101(10), 3583–3585 (2010)

Tan, J., Li, Y., Tan, X., Wu, H., Li, H., S. J. F. i. C. Yang,: Advances in pretreatment of straw biomass for sugar production. Front. Chem. (2021). https://doi.org/10.3389/fchem.2021.696030

Chen, Y., Mu, T.: Application of deep eutectic solvents in biomass pretreatment and conversion. Green Energy Environ. 4(2), 95–115 (2019)

Kalhor, P., Ghandi, K.: Deep eutectic solvents for pretreatment, extraction, and catalysis of biomass and food waste. Molecules 24(22), 4012 (2019)

Xu, H., Peng, J., Kong, Y., Liu, Y., Su, Z., Li, B., Song, X., Liu, S., Tian, W.: Key process parameters for deep eutectic solvents pretreatment of lignocellulosic biomass materials: a review. Biores. Technol. 310, 123416 (2020)

Alvarez-Vasco, C., Ma, R., Quintero, M., Guo, M., Geleynse, S., Ramasamy, K.K., Wolcott, M., Zhang, X.: Unique low-molecular-weight lignin with high purity extracted from wood by deep eutectic solvents (DES): a source of lignin for valorization. Green Chem. 18(19), 5133–5141 (2016)

Shen, X.-J., Chen, T., Wang, H.-M., Mei, Q., Yue, F., Sun, S., Wen, J.-L., Yuan, T.-Q., Sun, R.-C.J.A.S.C.: Structural and morphological transformations of lignin macromolecules during bio-based deep eutectic solvent (DES) pretreatment. ACS Sustain. Chem Eng 8(5), 2130–2137 (2019)

T. Sumiati and H. Suryadi, Potency of Deep Euteutic Solvent as an Alternative Solvent on Pretreatment Process of Lignocellulosic Biomass, in Journal of Physics: Conference Series, 2021, vol. 1764, no. 1, p. 012014: IOP Publishing.

Procentese, A., Raganati, F., Olivieri, G., Russo, M.E., Rehmann, L., Marzocchella, A.: Deep eutectic solvents pretreatment of agro-industrial food waste. Biotechnol. Biofuels 11(1), 1–12 (2018)

Satlewal, A., Agrawal, R., Bhagia, S., Sangoro, J., Ragauskas, A.J.: Natural deep eutectic solvents for lignocellulosic biomass pretreatment: recent developments, challenges and novel opportunities. Biotechnol. Adv. 36(8), 2032–2050 (2018)

Ong, V.Z., Wu, T.Y., Chu, K.K.L., Sun, W.Y., Shak, K.P.Y.: A combined pretreatment with ultrasound-assisted alkaline solution and aqueous deep eutectic solvent for enhancing delignification and enzymatic hydrolysis from oil palm fronds. Ind. Crops Prod. 160, 112974 (2021)

Mankar, A.R., Pandey, A., Modak, A., Pant, K.: Pretreatment of lignocellulosic biomass: a review on recent advances. Biores. Technol. 334, 125235 (2021)

Zhao, L., Sun, Z.-F., Zhang, C.-C., Nan, J., Ren, N.-Q., Lee, D.-J., Chen, C.: Advances in pretreatment of lignocellulosic biomass for bioenergy production: challenges and perspectives. Biores. Technol. 343, 126123 (2022)

C. Chatkaew, E. J. Panakkal, W. Rodiahwati, S. Kirdponpattara, S. Chuetor, M. Sriariyanun, and K. Cheenkachorn, Effect of sodium hydroxide pretreatment on released sugar yields from pomelo peels for biofuel production, in E3S Web of Conferences, 2021, vol. 302, p. 02015: EDP Sciences.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., Crocker, D.: Determination of structural carbohydrates and lignin in biomass. Lab. anal. Proced. 1617(1), 1–16 (2008)

Phitsuwan, P., Sakka, K., Ratanakhanokchai, K.: Structural changes and enzymatic response of Napier grass (Pennisetum purpureum) stem induced by alkaline pretreatment. Biores. Technol. 218, 247–256 (2016)

Mukwaya, V., Yu, W., Asad, R.A., Yagoub, H.: An environmentally friendly method for the isolation of cellulose nano fibrils from banana rachis fibers. Text. Res. J. 87(1), 81–90 (2017)

Waliszewska, B., Grzelak, M., Gaweł, E., Spek-Dźwigała, A., Sieradzka, A., Czekała, W.: Chemical characteristics of selected grass species from polish meadows and their potential utilization for energy generation purposes. Energies (2021). https://doi.org/10.3390/en14061669

Haldar, D., Purkait, M.K.J.B.C., Biorefinery,: Thermochemical pretreatment enhanced bioconversion of elephant grass (Pennisetum purpureum) insight on the production of sugars and lignin. Biomass Convers. Biorefinery 12(2), 1–14 (2020)

Sluiter, A., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D.: Determination of extractives in biomass: laboratory analytical procedure (LAP). Natl. Renew. Energy Lab. 1617, 1–9 (2008)

Zhang, H., Lang, J., Lan, P., Yang, H., Lu, J., Wang, Z.: Study on the dissolution mechanism of cellulose by ChCl-based deep eutectic solvents. Materials 13(2), 278 (2020)

Lu, Y., He, Q., Fan, G., Cheng, Q., Song, G.: Extraction and modification of hemicellulose from lignocellulosic biomass: a review. Green Process. Synth. 10(1), 779–804 (2021)

Yu, Q., Zhang, A., Wang, W., Chen, L., Bai, R., Zhuang, X., Wang, Q., Wang, Z., Yuan, Z.: Deep eutectic solvents from hemicellulose-derived acids for the cellulosic ethanol refining of Akebia’herbal residues. Biores. Technol. 247, 705–710 (2018)

Hou, X.-D., Li, A.-L., Lin, K.-P., Wang, Y.-Y., Kuang, Z.-Y., Cao, S.-L.: Insight into the structure-function relationships of deep eutectic solvents during rice straw pretreatment. Biores. Technol. 249, 261–267 (2018)

Zhang, H., Han, L., Dong, H.: An insight to pretreatment, enzyme adsorption and enzymatic hydrolysis of lignocellulosic biomass: Experimental and modeling studies. Renew. Sustain. Energy Rev. 140, 110758 (2021)

Sigma-Aldrich. (2022). Safety datasheet. Available: https://www.sigmaaldrich.com/ZA/en/sds/sigma/sae0020

Chen, H., Han, Y., Xu, J.: Simultaneous saccharification and fermentation of steam exploded wheat straw pretreated with alkaline peroxide. Process Biochem. 43(12), 1462–1466 (2008)

Gundupalli, M.P., Tantayotai, P., Panakkal, E.J., Chuetor, S., Kirdponpattara, S., Thomas, A.S.S., Sharma, B.K., Sriariyanun, M.: Hydrothermal pretreatment optimization and deep eutectic solvent pretreatment of lignocellulosic biomass: an integrated approach. Bioresour. Technol. Rep 17, 100957 (2022)

Xing, W., Xu, G., Dong, J., Han, R., Ni, Y.: Novel dihydrogen-bonding deep eutectic solvents: pretreatment of rice straw for butanol fermentation featuring enzyme recycling and high solvent yield. Chem. Eng. J. 333, 712–720 (2018)

Okuofu, S.I., Gerrano, A.S., Singh, S., Pillai, S.: Deep eutectic solvent pretreatment of Bambara groundnut haulm for enhanced saccharification and bioethanol production. Biomass Convers. Biorefinery 12, 1–9 (2020)

Wang, Z., He, X., Yan, L., Wang, J., Hu, X., Sun, Q., Zhang, H.: Enhancing enzymatic hydrolysis of corn stover by twin-screw extrusion pretreatment. Ind. Crops Prod. 143, 111960 (2020)

Wang, C., Li, H., Li, M., Bian, J., Sun, R.: Revealing the structure and distribution changes of Eucalyptus lignin during the hydrothermal and alkaline pretreatments. Sci. Rep. 7(1), 1–10 (2017)

Nor, N.A.M., Mustapha, W.A.W., Hassan, O.JPc.: Deep eutectic solvent (DES) as a pretreatment for oil palm empty fruit bunch (OPEFB) in sugar production. Procedia Chem. 18, 147–154 (2016)

Jiang, L.-Q., Fang, Z., Li, X.-K., Luo, J.: Production of 2, 3-butanediol from cellulose and Jatropha hulls after ionic liquid pretreatment and dilute-acid hydrolysis. AMB Express 3(1), 1–8 (2013)

Ergun, R., Guo, J., Huebner-Keese, B.: Cellulose in Encyclopedia of Food and Health. In: BenjaminCaballero, P.M.F.F.T. (ed.) Elsevier. Amsterdam (2016)

He, J., Cui, S., Wang, Sy.: Preparation and crystalline analysis of high-grade bamboo dissolving pulp for cellulose acetate. J. Appl. Polym. Sci. 107(2), 1029–1038 (2008)

Zulkiple, N., Maskat, M.Y., Hassan, O.JPc.: Pretreatment of oil palm empty fruit fiber (OPEFB) with aquaeous ammonia for high production of sugar. Procedia Chem. 18, 155–161 (2016)

Funding

This work was supported by the African Center of Excellence in Materials, Product Development and Nanotechnology (MAPRONANO ACE) funded by the World Bank and Government of Uganda [Project Identification P151847, IDA Number 5797-UG]. Ayaa Fildah also acknowledges support received from The Professor Daramola Development Fund that enabled her to visit and supervise this study at the University of Pretoria. The Chemical industries education and training authority (CHIETA) also funded Nothando Masuku Faith's training at the University of Pretoria.

Author information

Authors and Affiliations

Contributions

All authors contributed to the successful completion of this study. NMF, AF, OCM and SAI conceptualized the project.MOD, JBK, SAI, AF and OC Mary reviewed the first draft. MOD and JBK were responsible for funding acquisition and project administration.

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Masuku, N.F., Ayaa, F., Onyelucheya, C.M. et al. Fractionation of Yellow Thatching Grass (Hyparrhenia filipendula) for Sugar Production Using Combined Alkaline and Deep Eutectic Solvent Pretreatment. Waste Biomass Valor 14, 2609–2620 (2023). https://doi.org/10.1007/s12649-022-02013-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-02013-3