Abstract

Purpose

Furfural is a furanic aldehyde obtained from the acid treatment of pentoses found in lignocellulosic material. It has excellent physical and chemical properties that allow its application in the generation of fertilizers, antacids, plastics, paints, fungicides, among many others, besides having important derivatives for the chemical industry, such as furfuryl alcohol and tetrahydrofuran. The production potential of this compound in Brazil is enormous as the country is the world’s largest producer of sugarcane, and the surplus bagasse of this activity is a source of lignocellulosic biomass.

Methods

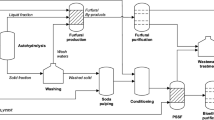

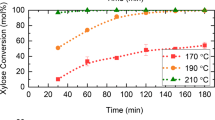

This work experimentally optimized two routes for furfural production: (1) from sugarcane biomass and (2) from the hemicellulosic hydrolysate. Additionally, techno-economic analyses of the optimal sceneries were developed.

Results

For the simulation, an initial flow of 71 tonne h−1 of sugarcane biomass was used: case 1 produced 3.93 tonne h−1 of furfural with a heating demand of 44.7 MJ kg−1 (688.7 kW tonne−1 of feed); case 2 produced 2.96 tonne h−1 of furfural with a heating demand of 106.3 MJ kg−1 (1230.3 kW tonne−1 of feed). An economic evaluation of two cases resulted in revenues of U$ 50 million and U$ 31 million for cases 1 and 2, respectively. Furthermore, the internal rate of return (IRR, %) for both cases (72 and 56%, respectively) was greater than the rate of return (ROR = 15%), indicating that the investment will earn profits.

Conclusion

Likewise, the integration of furfural production to the first and second-generation (1G and 2G) ethanol production chain could sustain the process, favoring the full use of biomass generating higher value-added bioproducts.

Graphical Abstract

Similar content being viewed by others

Data Availability

The authors declare that all data supporting the findings of this study are available within the article and its supplementary information files.

References

Aguiar, A., Milessi, T.S., Mulinari, D.R., Lopes, M.S., da Costa, S.M., Candido, R.G.: Sugarcane straw as a potential second generation feedstock for biorefinery and white biotechnology applications. Biomass Bioenergy 144, 105896 (2021). https://doi.org/10.1016/j.biombioe.2020.105896

Watanabe, M.D.B., Morais, E.R., Cardoso, T.F., Chagas, M.F., Junqueira, T.L., Carvalho, D.J., Bonomi, A.: Process simulation of renewable electricity from sugarcane straw: techno-economic assessment of retrofit scenarios in Brazil. J. Clean. Prod. 254, 120081 (2020). https://doi.org/10.1016/j.jclepro.2020.120081

Jung, H.J., Oh, K.K.: Production of bio-based chemicals, acetic acid and furfural, through low-acid hydrothermal fractionation of Pine wood (Pinus densiflora) and combustion characteristics of the residual solid. Fuel 11, 7435 (2021)

Morais, W.G., Pacheco, T.F., Corrêa, P.S., Martins, A.A., Mata, T.M., Caetano, N.S.: Acid pretreatment of sugarcane biomass to obtain hemicellulosic hydrolisate rich in fermentable sugar. Energy Rep. 6, 18–23 (2020). https://doi.org/10.1016/j.egyr.2020.10.015

Moraes, E.D.J.C., Silva, D.D.V., Dussán, K.J., et al.: Xylitol-sweetener production from barley straw: optimization of acid hydrolysis condition with the energy consumption simulation. Waste Biomass Valoriz. 11, 1837–1849 (2018)

Dussán, K.J., Silva, D.D.V., Perez, V.H., da Silva, S.S.: Evaluation of oxygen availability on ethanol production from sugarcane bagasse hydrolysate in a batch bioreactor using two strains of xylose-fermenting yeast. Renew. Energy 87, 703–710 (2016). https://doi.org/10.1016/j.renene.2015.10.065

Silva, D.D.V., Dussán, K.J., Idarraga, A., et al.: Production and purification of xylitol by Scheffersomyces amazonenses via sugarcane hemicellulosic hydrolysate. Biofuels Bioprod. Biorefin. 14, 344–356 (2020). https://doi.org/10.1002/bbb.2085

Silva, J.F.L., Selicani, M.A., Junqueira, T.L., Klein, B.C., Vaz Júnior, S., Bonomi, A.: Integrated furfural and first generation bioethanol production: process simulation and techno-economic analysis. Braz. J. Chem. Eng. 34, 623–634 (2017). https://doi.org/10.1590/0104-6632.20170343s20150643

Contreras-Zarazúa, G., Martin-Martin, M., Sánchez-Ramirez, E., Segovia-Hernández, J.G.: Furfural production from agricultural residues using different intensified separation and pretreatment alternatives. Economic and environmental assessment. Chem. Eng. Process.-Process Intensif. 171, 108569 (2022). https://doi.org/10.1016/j.cep.2021.108569

Irmak, S.: Biomass as raw material for production of high-value products. In: Tumuluru, J.S. (ed.) Biomass Volume Estimation and Valorization for Energy. IntechOpen, Rijeka (2017)

Liu, L., Chang, H.-M., Jameel, H., Park, S.: Furfural production from biomass pretreatment hydrolysate using vapor-releasing reactor system. Bioresour. Technol. 252, 165–171 (2018). https://doi.org/10.1016/j.biortech.2018.01.006

Mohamad, N., Mohamad Yusof, N.N., Yong, T.L.-K.: Furfural production under subcritical alcohol conditions: effect of reaction temperature, time, and types of alcohol. J. Jpn. Instit. Energy 96, 279–284 (2017). https://doi.org/10.3775/jie.96.279

Machado, G., Leon, S., Santos, F., Lourega, R., Dullius, J., Mollmann, M., Eichler, P.: Literature review on furfural production from lignocellulosic biomass. Nat. Resour. 07, 115–129 (2016). https://doi.org/10.4236/nr.2016.73012

Mamman, A.S., Lee, J.-M., Kim, Y.-C., et al.: Furfural: hemicellulose/xylosederived biochemical. Biofuels Bioprod. Biorefin. 2, 438–454 (2008). https://doi.org/10.1002/bbb.95

Gebre, H., Fisha, K., Kindeya, T., Gebremichal, T.: Synthesis of furfural from bagasse. Int. Lett. Chem. Phys. Astron. 57, 72–84 (2015). https://doi.org/10.18052/www.scipress.com/ILCPA.57.72

Lee, C.B.T.L., Wu, T.Y.: A review on solvent systems for furfural production from lignocellulosic biomass. Renew. Sustain. Energy Rev. 137, 110172 (2021). https://doi.org/10.1016/j.rser.2020.110172

Dhepe, P.L., Sahu, R.: A solid-acid-based process for the conversion of hemicellulose. Green Chem. 12, 2153–2156 (2010). https://doi.org/10.1039/C004128A

Kabbour, M., Luque, R.: Chapter 10—furfural as a platform chemical: from production to applications. In: Saravanamurugan, S., Pandey, A., Li, H., Riisager, A. (eds.) Biomass, Biofuels, Biochemicals, pp. 283–297. Elsevier, Amsterdam (2020)

Rodriguez, A., Rache, L.Y., Brijaldo, M.H., Silva, L.P.C., Esteves, L.M.: Common reactions of furfural to scalable process of residual biomass%. J Ciencia en Desarrollo. 11, 63–80 (2020)

Binder, J.B., Blank, J.J., Cefali, A.V., Raines, R.T.: Synthesis of furfural from xylose and xylan. Chemsuschem 3, 1268–1272 (2010). https://doi.org/10.1002/cssc.201000181

Delbecq, F., Wang, Y., Muralidhara, A., ElOuardi, K., Marlair, G., Len, C.: Hydrolysis of hemicellulose and derivatives—a review of recent advances in the production of furfural. Front Chem. 6, 146 (2018). https://doi.org/10.3389/fchem.2018.00146

Ntimbani, R.N., Farzad, S., Görgens, J.F.: Techno-economics of one-stage and two-stage furfural production integrated with ethanol co-production from sugarcane lignocelluloses. Biofuels Bioprod. Biorefin. 15, 1900–1911 (2021). https://doi.org/10.1002/bbb.2289

Ntimbani, R.N., Farzad, S., Görgens, J.F.: Techno-economic assessment of one-stage furfural and cellulosic ethanol co-production from sugarcane bagasse and harvest residues feedstock mixture. Ind. Crops Prod. 162, 113272 (2021). https://doi.org/10.1016/j.indcrop.2021.113272

Conab: Acompanhamento da safra brasileira de cana-de-açúcar. https://www.conab.gov.br/info-agro/safras/graos/boletim-da-safra-de-graos. (2020) Accessed V.7—SAFRA 2019/20 - N. 3 7

Wang, Y.: Synthesis and conversion of furfural-batch versus continuous flow. https://tel.archives-ouvertes.fr/tel-02171959/document. (2019) Accessed NNT: 2019COMP2474 PhD

Clauser, N.M., Gutiérrez, S., Area, M.C., Felissia, F.E., Vallejos, M.E.: Small-sized biorefineries as strategy to add value to sugarcane bagasse. Chem. Eng. Res. Des. 107, 137–146 (2016). https://doi.org/10.1016/j.cherd.2015.10.050

Pulicharla, R., Lonappan, L., Brar, S.K., Verma, M.P.: (2016) Production of renewable C5 platform chemicals and potential applications. In: Platform Chemical Biorefiner

Sherif, N., Gadalla, M., Kamel, D.: Acid–hydrolysed furfural production from rice straw bio-waste: process synthesis, simulation, and optimisation. S. Afr. J. Chem. Eng. 38, 34–40 (2021). https://doi.org/10.1016/j.sajce.2021.08.002

Yemiş, O., Mazza, G.: Acid-catalyzed conversion of xylose, xylan and straw into furfural by microwave-assisted reaction. Bioresour Technol. 102, 7371–7378 (2011). https://doi.org/10.1016/j.biortech.2011.04.050

Sahu, R., Dhepe, P.L.: A one-pot method for the selective conversion of hemicellulose from crop waste into C5 sugars and furfural by using solid acid catalysts. Chemsuschem 5, 751–761 (2012). https://doi.org/10.1002/cssc.201100448

Gürbüz, E.I., Wettstein, S.G., Dumesic, J.A.: Conversion of hemicellulose to furfural and levulinic acid using biphasic reactors with alkylphenol solvents. Chemsuschem 5, 383–387 (2012). https://doi.org/10.1002/cssc.201100608

Rong, C., Ding, X., Zhu, Y., et al.: Production of furfural from xylose at atmospheric pressure by dilute sulfuric acid and inorganic salts. Carbohydr Res. 350, 77–80 (2012). https://doi.org/10.1016/j.carres.2011.11.023

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., Crocker, D.: Determination of Structural Carbohydrates and Lignin in Biomass. https://www.nrel.gov/docs/gen/fy13/42618.pdf. (2012) Accessed NREL/TP-510-42618.

Palacios-Bereche, R., Nebra, S.: Thermodynamic modeling of a cogeneration system for a sugarcane mill using ASPEN PLUS, difficulties and challenges. In: 20th International Congress of Mechanical Engineering, Gramado, RS, Brazil, pp. 15–20 (2009)

Wooley, R., Putsche, V.: Development of an ASPEN PLUS Physical Property Database for Biofuels Components, p. 38. National Renewable Energy Laboratory, Golden (1996)

BCB, B.C.d.B.: Cotação Dolar e Euro. https://www.bcb.gov.br/. (2021) Accessed 07 May 2021.

Abatzoglou, N., Koeberle, P.G., Chornet, E., Overend, R.P., Koukios, E.G.: Dilute acid hydrolysis of lignocellulosics: an application to medium consistency suspensions of hardwoods using a plug flow reactor. Can. J. Chem. Eng. 68, 627–638 (1990). https://doi.org/10.1002/cjce.5450680414

Strømsnes, L.M.: Process Modeling of a biorefinery for integrated production of ethanol and furfural in HYSYS. https://ntnuopen.ntnu.no/ntnu-xmlui/bitstream/handle/11250/2411071/14700_FULLTEXT.pdf?sequence=1&isAllowed=y. (2016). Accessed 10 May 2019.

Souza, Z.J.: Conjuntura—A comercialização no setor elétrico brasileiro e a bioeletricidade. https://revistarpanews.com.br/conjuntura-a-comercializacao-no-setor-eletrico-brasileiro-e-a-bioeletricidade/#:~:text=A%20produ%C3%A7%C3%A3o%20de%20bioeletricidade%20para,em%20rela%C3%A7%C3%A3o%20ao%20ano%20anterior.&text=A%20bioeletricidade%20tem%20um%20perfil,rela%C3%A7%C3%A3o%20ao%20ambiente%20de%20comercializa%C3%A7%C3%A3o. (2019). Accessed 09 May 2021

Tom Wolf, P.E.: Lang factor cost estimates. http://prjmgrcap.com/langfactorestimating.html. (2013). Accessed 07 May 2021

CE, C.E.: Plant Cost Index. https://www.chemengonline.com/site/plant-cost-index/. (2021). Accessed 07 May 2021

ENEL: Tarifa de Energia Elétrica. https://www.eneldistribuicaosp.com.br/corporativo-poder-publico/tarifa-de-energia-eletrica. (2021) Accessed 07 May 2021.

JornalCana: Quanto custa o bagaço? . https://jornalcana.com.br/quanto-custa-o-bagaco-confira-aqui. (2019) Accessed 07 May 2021.

SAAE: Como calcular sua conta. http://www.saaegarca.sp.gov.br/html2/modules/fmcontent/content.php?topic=paginas&id=11&page=como-calcular-sua-conta. (2021) Accessed 07 May 2021.

Punsuvon, V., Vaithanomsat, P., Iiyama, K.: Simultaneous production of alpha-cellulose and furfural from bagasse by steam explosion pretreatment. Maejo Int. J. Sci. 2, 182–191 (2008)

Riansa-ngawong, W., Prasertsan, P.: Optimization of furfural production from hemicellulose extracted from delignified palm pressed fiber using a two-stage process. Carbohydr. Res. 346, 103–110 (2011). https://doi.org/10.1016/j.carres.2010.10.009

Fúnez-Núñez, I., García-Sancho, C., Cecilia, J.A., Moreno-Tost, R., Serrano-Cantador, L., Maireles-Torres, P.: Recovery of pentoses-containing olive stones for their conversion into furfural in the presence of solid acid catalysts. Process Saf. Environ. Prot. 143, 1–13 (2020). https://doi.org/10.1016/j.psep.2020.06.033

Bariani, M., Boix, E., Cassella, F., Cabrera, M.N.: Furfural production from rice husks within a biorefinery framework. Biomass Convers. Biorefin. 11, 781–794 (2020). https://doi.org/10.1007/s13399-020-00810-1

Vedernikovs, N.: Differential catalysis of depolymerisation and dehydration reactions: producing furfural from plant biomass. J. Renew. Mater. 8, 661–674 (2020). https://doi.org/10.32604/jrm.2020.09274

Funding

The authors are grateful to the São Paulo Research Foundation (FAPESP): grant numbers #2016/23209-0, #2017/19145-0, and #2017/14389-8" for financially supporting the current study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Research Involving Human and Animal Rights

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Almeida, S.G.C., Mello, G.F., Kovacs, T.K. et al. Furfural Production Through Two Bioconversion Routes: Experimental Optimization and Process Simulation. Waste Biomass Valor 13, 4013–4025 (2022). https://doi.org/10.1007/s12649-022-01825-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01825-7