Abstract

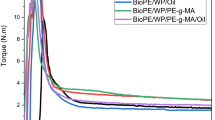

This study evaluated the mechanical, thermal, water soak, and rheological properties of mixed plastic waste (MPW) in combination with fibers derived from residual hops bines and coupling agents or dicumyl peroxide (DCP) to form composite materials. Hop bines were pulped to afford individual hop fibers (HF) in 45% yield with 78% carbohydrate content. The MPW comprised mainly of PET, paper, PE and PEVA. Tensile moduli and strength of the formulations ranged between 1.1 and 2.0 GPa and 11 and 14 MPa, respectively. The addition of hops fiber (HF) improved the tensile modulus of the formulations by 40%. Tensile strength was improved by the addition of coupling agents by 11% and this was supported by determining the adhesion factor by dynamic mechanical analysis. However, the addition of DCP resulted in a reduction of tensile properties. The melt properties of the formulations showed shear thinning behavior and followed the power-law model. The water absorption tests for most of the MPW formulations gave an 11% weight gain over 83 d except for the DCP treated composites (14–16%). The fabricated composites can be used in non-structural applications such as (garden trim, siding, pavers, etc.).

Graphical Abstract

Similar content being viewed by others

Data Availability

Data will be available on reasonable request.

References

“National Overview: Facts and Figures on Materials, Wastes and Recycling | Facts and Figures about Materials, Waste and Recycling | US EPA.” https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials. Accessed 22 Feb 2021.

Sigler, M.: The effects of plastic pollution on aquatic wildlife: current situations and future solutions. Water Air Soil Pollut (2014). https://doi.org/10.1007/s11270-014-2184-6

Kolapkar, S.S., Zinchik, S., Xu, Z., McDonald, A.G., Bar-Ziv, E.: Integration of thermal treatment and extrusion by compounding for processing various wastes for energy applications. Energy Fuels 35(15), 12227–12236 (2021). https://doi.org/10.1021/acs.energyfuels.1c01836

Jayaraman, K., Bhattacharyya, D.: Mechanical performance of woodfibre-waste plastic composite materials. Resour. Conserv. Recycl. 41(4), 307–319 (2004). https://doi.org/10.1016/j.resconrec.2003.12.001

Badrinath, R., Senthilvelan, T.: Comparative investigation on mechanical properties of banana and sisal reinforced polymer based composites. Procedia Mater. Sci. 5, 2263–2272 (2014). https://doi.org/10.1016/j.mspro.2014.07.444

Hsissou, R., Seghiri, R., Benzekri, Z., Hilali, M., Rafik, M., Elharfi, A.: Polymer composite materials: a comprehensive review. Compos. Struct. 262, 113640 (2021). https://doi.org/10.1016/J.COMPSTRUCT.2021.113640

Aljnaid, M., Banat, R.: Effect of coupling agents on the olive pomace-filled polypropylene composite. E-Polymers 21(1), 377–390 (2021). https://doi.org/10.1515/EPOLY-2021-0038/ASSET/GRAPHIC/J_EPOLY-2021-0038_FIG_011.JPG

Mohanty, S., Verma, S.K., Nayak, S.K.: Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos. Sci. Technol. 66(3–4), 538–547 (2006). https://doi.org/10.1016/j.compscitech.2005.06.014

Gu, J., Xu, H., Wu, C.: Thermal and crystallization properties of HDPE and HDPE/PP blends modified with DCP. Adv. Polym. Technol. 33(1), 1–5 (2014). https://doi.org/10.1002/adv.21384

Lee S. -Y., Kang I. -A., Park B. -S., Doh G. -H., and Park B. -D., “Effects of Filler and Coupling Agent on the Properties of Bamboo Fiber-Reinforced Polypropylene Composites:,” http://dx.doi.org/https://doi.org/10.1177/0731684408094070, vol. 28, no. 21, pp. 2589–2604, Sep. 2008, doi: https://doi.org/10.1177/0731684408094070.

Alkbir, M.F.M., Sapuan, S.M., Nuraini, A.A., Ishak, M.R.: Fibre properties and crashworthiness parameters of natural fibre-reinforced composite structure: a literature review. Compos. Struct. 148, 59–73 (2016). https://doi.org/10.1016/J.COMPSTRUCT.2016.01.098

Lei, Y., Wu, Q.: Wood plastic composites based on microfibrillar blends of high density polyethylene/poly(ethylene terephthalate). Biores. Technol. 101, 3665–3671 (2010). https://doi.org/10.1016/j.biortech.2009.12.069

Pérez-Fonseca, A.A., Robledo-Ortíz, J.R., Moscoso-Sánchez, F.J., Fuentes-Talavera, F.J., Rodrigue, D., González-Núñez, R.: Self-hybridization and coupling agent effect on the properties of natural Fiber/HDPE composites. J. Polym. Environ. 23(1), 126–136 (2015). https://doi.org/10.1007/s10924-014-0706-3

Shahzad, A.: Hemp fiber and its composites-a review. https://doi.org/10.1177/0021998311413623.

Musio, S., Müssig, J., Amaducci, S.: Optimizing hemp fiber production for high performance composite applications. Front. Plant Sci. 9, 1702 (2018). https://doi.org/10.3389/FPLS.2018.01702

Shah, N., Fehrenbach, J., Ulven, C.A.: Hybridization of hemp fiber and recycled-carbon fiber in polypropylene composites. Sustainability (2019). https://doi.org/10.3390/su11113163

Mazzanti, V., Mollica, F., el Kissi, N.: Rheological and mechanical characterization of polypropylene-based wood plastic composites. Polym. Compos. 37(12), 3460–3473 (2016). https://doi.org/10.1002/pc.23546

Ogah, A.O., Afiukwa, J.N., Nduji, A.A.: Characterization and comparison of rheological properties of agro fiber filled high-density polyethylene bio-composites. Open J. Polym. Chem. 04(01), 12–19 (2014). https://doi.org/10.4236/ojpchem.2014.41002

Zou, Y., Reddy, N., Yang, Y.: Using hop bines as reinforcements for lightweight polypropylene composites. J. Appl. Polym. Sci. 116(4), 2366–2373 (2010). https://doi.org/10.1002/APP.31770

Adefisan, O.O., McDonald, A.G.: Evaluation of the strength, sorption and thermal properties of bamboo plastic composites. Maderas 21(1), 3–14 (2019). https://doi.org/10.4067/S0718-221X2019005000101

Reddy, N., Yang, Y.: Properties of natural cellulose fibers from hop stems. Carbohydr. Polym. 77(4), 898–902 (2009). https://doi.org/10.1016/j.carbpol.2009.03.013

Ariff, Z.M., Ariffin, A., Rahim, N.A.A., Jikan, S.S.: Rheological behaviour of polypropylene through extrusion and capillary rheometry. InTech, pp. 29–48, 2012, [Online]. https://www.intechopen.com/books/polypropylene/rheological-behaviour-of-polypropylene-through-extrusion-and-capillary-rheometry

Hsissou, R., Bekhta, A., Dagdag, O., el Bachiri, A., Rafik, M., Elharfi, A.: Rheological properties of composite polymers and hybrid nanocomposites. Heliyon 6(6), e04187 (2020). https://doi.org/10.1016/J.HELIYON.2020.E04187

Mazzanti, V., Mollica, F.: A review of wood polymer composites rheology and its implications for processing. Polymers 12, 2304 (2020). https://doi.org/10.3390/POLYM12102304

Shevelko, V.P.: Polymer and composite rheology, second edition. IEEE Electr. Insul. Mag. 17(2), 68 (2001). https://doi.org/10.1109/MEI.2001.917553

Amaducci, S., Müssig, J., Zatta, A., Venturi, G.: An innovative production system for hemp fibre for textile destinations : from laboratory results to industrial validation. In: International Conference on Flax and Other Bast Plants, pp. 104–117 (2008).

Aurelia, C., Murdiati, A.S., Ningrum, A.: Effect of sodium hydroxide and sodium hypochlorite on the physicochemical characteristics of jack bean skin (Canavalia ensiformis). Pak. J. Nutr. 18(2), 193–200 (2019). https://doi.org/10.3923/pjn.2019.193.200

Iiyama, K., Wallis, A.F.A.: An improved acetyl bromide procedure for determining lignin in woods and wood pulps. Wood Sci. Technol. 22(3), 271–280 (1988). https://doi.org/10.1007/BF00386022

Green, T.R., Popa, R.: A simple assay for monitoring cellulose in paper-spiked soil. J. Polym. Environ. 18(4), 634–637 (2010). https://doi.org/10.1007/s10924-010-0239-3

Xu, Z., et al.: Bypassing energy barriers in fiber-polymer torrefaction. Front. Energy Res. (2021). https://doi.org/10.3389/fenrg.2021.643371

Rodi, E.G., Langlois, V., Renard, E., Sansalone, V., Lemaire, T.: Biocomposites based on poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBHV) and Miscanthus giganteus fibers with improved fiber/matrix interface. Polymers (2018). https://doi.org/10.3390/polym10050509

Orji, B.O., McDonald, A.G.: Evaluation of the mechanical, thermal and rheological properties of recycled polyolefins rice-hull composites. Materials (2020). https://doi.org/10.3390/ma13030667

Kunej, U., Mikulič-Petkovšek, M., Radišek, S., Štajner, N.: Changes in the phenolic compounds of hop (Humulus lupulus l.) induced by infection with verticillium nonalfalfae, the causal agent of hop verticillium wilt. Plants 9(7), 1–16 (2020). https://doi.org/10.3390/plants9070841

Detmann, E., de Oliveira Franco, M., Gomes, D.Í., Barbosa, M.M., de Campos Valadares Filho, S.: Notas Científicas: Protein contamination on klason lignin contents in tropical grasses and legumes. Pesquisa Agropecuaria Brasileira 49(12), 994–997 (2014). https://doi.org/10.1590/S0100-204X2014001200010.

Chércoles Asensio, R., San Andrés Moya, M., de La Roja, J.M., Gómez, M.: Analytical characterization of polymers used in conservation and restoration by ATR-FTIR spectroscopy. Anal. Bioanal. Chem. 395(7), 2081–2096 (2009). https://doi.org/10.1007/s00216-009-3201-2

Jung, M.R., et al.: Validation of ATR FT-IR to identify polymers of plastic marine debris, including those ingested by marine organisms. (2018). https://doi.org/10.1016/j.marpolbul.2017.12.061.

Mayo, D.W., Miller, F.A., Hannah, R.W.: Course Notes on the Interpretation of Infrared and Raman Spectra. Wiley, Hoboken (2004). https://doi.org/10.1002/0471690082

Ahmad, E.E.M., Luyt, A.S.: Effects of organic peroxide and polymer chain structure on morphology and thermal properties of sisal fibre reinforced polyethylene composites. Composite A 43(4), 703–710 (2012). https://doi.org/10.1016/j.compositesa.2011.12.011

Ndiaye, D., Tidjani, A.: Effects of coupling agents on thermal behavior and mechanical properties of wood flour/polypropylene composites. J Compos Mater 46(24), 3067–3075 (2012). https://doi.org/10.1177/0021998311435675

Gloor, P.E., Tang, Y., Kostanska, A.E., Hamielec, A.E.: Chemical modification of polyolefins by free radical mechanisms: a modelling and experimental study of simultaneous random scission, branching and crosslinking. Polymer 35(5), 1012–1030 (1994). https://doi.org/10.1016/0032-3861(94)90946-6

Aljnaid, M., Banat, R.: Effect of coupling agents on the olive pomace-filled polypropylene composite. Polymers 21(1), 377–390 (2021). https://doi.org/10.1515/epoly-2021-0038

Wang, X., Yu, Z., McDonald, A.G.: Effect of different reinforcing fillers on properties, interfacial compatibility and weatherability of wood-plastic composites. J. Bionic Eng. 16(2), 337–353 (2019). https://doi.org/10.1007/s42235-019-0029-0

da Costa, H.M., Ramos, V.D., Rocha, M.C.G.: Rheological properties of polypropylene during multiple extrusion. Polym. Testing 24(1), 86–93 (2005). https://doi.org/10.1016/J.POLYMERTESTING.2004.06.006

Sapieha, S., Allard, P., Zang, Y.H.: Dicumyl peroxide-modified cellulose/LLDPE composites. J. Appl. Polym. Sci. 41(9–10), 2039–2048 (1990). https://doi.org/10.1002/APP.1990.070410910

Gu, R., Kokta, B.V.: Mechanical properties of PP composites reinforced with BCTMP aspen fiber. J. Thermoplast. Compos. Mater. 23(4), 513–542 (2009). https://doi.org/10.1177/0892705709355232

Ou, R., Xie, Y., Wolcott, M.P., Yuan, F., Wang, Q.: Effect of wood cell wall composition on the rheological properties of wood particle/high density polyethylene composites. Compos. Sci. Technol. 93, 68–75 (2014). https://doi.org/10.1016/j.compscitech.2014.01.001

Wei, L., Stark, N.M., McDonald, A.G.: Interfacial improvements in biocomposites based on poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) bioplastics reinforced and grafted with α-cellulose fibers. Green Chem. 17(10), 4800–4814 (2015). https://doi.org/10.1039/c5gc01568e

Dealy, J.M., Wissbrun, K.F.: Melt Rheology and Its Role in Plastics Processing. Melt Rheol Role Plast Process (1990). https://doi.org/10.1007/978-94-009-2163-4

Akil, H., Zamri, M.H.: Performance of natural fiber composites under dynamic loading. Nat. Fibre Compos. Mater. Process. Appl. (2013). https://doi.org/10.1533/9780857099228.3.323

Ornaghi, H.L., Bolner, A.S., Fiorio, R., Zattera, A.J., Amico, S.C.: Mechanical and dynamic mechanical analysis of hybrid composites molded by resin transfer molding. J. Appl. Polym. Sci. (2010). https://doi.org/10.1002/app.32388

Alkbir, M.F.M., Sapuan, S.M., Nuraini, A.A., Ishak, M.R.: Fibre properties and crashworthiness parameters of natural fibre-reinforced composite structure: a literature review. Compos. Struct. 148, 59–73 (2016). https://doi.org/10.1016/j.compstruct.2016.01.098

Ochi, S.: Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 40(4–5), 446–452 (2008). https://doi.org/10.1016/j.mechmat.2007.10.006

Sardot, T., Smith, G., McDonald, A.G.: Valorizing mixed plastic wastes from cardboard recycling by amendment with wood, cement and ash. J. Reinf. Plast. Compos. 31(21), 1488–1497 (2012). https://doi.org/10.1177/0731684412459984

Rodi, E.G., Langlois, V., Renard, E., Sansalone, V., Lemaire, T.: Biocomposites based on poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBHV) and Miscanthus giganteus fibers with improved fiber/matrix interface. Polymers (2018). https://doi.org/10.3390/POLYM10050509

Fabiyi, J.S., McDonald, A.G.: Effect of wood species on property and weathering performance of wood plastic composites. Composite A 41(10), 1434–1440 (2010). https://doi.org/10.1016/j.compositesa.2010.06.004

Cisneros-López, E.O., González-López, M.E., Pérez-Fonseca, A.A., González-Núñez, R., Rodrigue, D., Robledo-Ortíz, J.R.: Effect of fiber content and surface treatment on the mechanical properties of natural fiber composites produced by rotomolding. Compos. Interfaces 24(1), 35–53 (2017). https://doi.org/10.1080/09276440.2016.1184556

Azizi, H., Ghasemi, I.: Reactive extrusion of polypropylene: Production of controlled-rheology polypropylene (CRPP) by peroxide-promoted degradation. Polym. Test. 23(2), 137–143 (2004). https://doi.org/10.1016/S0142-9418(03)00072-2

Gu, R., Kokta, B.V.: Mechanical properties of pp composites reinforced with BCTMP aspen fiber. J. Thermoplast. Compos. Mater. 23(4), 513–542 (2010). https://doi.org/10.1177/0892705709355232

Stark, N.M., Berger, M.J.: Effect of particle size on properties of wood-flour reinforced polypropylene composites. In: Fourth International Conference on Woodfiber-Plastic Composites, pp. 134–143\r324 (1997)

Liu, Y.H., Xu, J.Q., Ding, H.J.: Mechanical behavior of a fiber end in short fiber reinforced composites. Int. J. Eng. Sci. 37(6), 753–770 (1999). https://doi.org/10.1016/S0020-7225(98)00096-2

Bouafif, H., Koubaa, A., Perré, P., Cloutier, A.: Effects of fiber characteristics on the physical and mechanical properties of wood plastic composites. Composite A 40(12), 1975–1981 (2009). https://doi.org/10.1016/j.compositesa.2009.06.003

Holbery, J., Houston, D.: Natural-fiber-reinforced polymer composites in automotive applications. Jom 58(11), 80–86 (2006). https://doi.org/10.1007/s11837-006-0234-2

Sfiligoj, M., Hribernik, S., Stana, K., Kree, T.: Plant fibres for textile and technical applications. Adv. Agrophys. Res. (2013). https://doi.org/10.5772/52372

Joseph, P.V., Rabello, M.S., Mattoso, L.H.C., Joseph, K., Thomas, S.: Environmental effects on the degradation behaviour of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 62(10–11), 1357–1372 (2002). https://doi.org/10.1016/S0266-3538(02)00080-5

Kanazawa H.: Improvement of hydrophilic property of plastic materials and its application. Sci. Rep. Fukushima Univ. no. 67, pp. 45–59

Bouafif, H., Koubaa, A., Perré, P., Cloutier, A., Riedl, B.: Wood particle/high-density polyethylene composites: thermal sensitivity and nucleating ability of wood particles. J. Appl. Polym. Sci. 113(1), 593–600 (2009). https://doi.org/10.1002/app.30129

Pérez-Fonseca, A.A., Arellano, M., Rodrigue, D., González-Núñez, R., Robledo-Ortíz, J.R.: Effect of coupling agent content and water absorption on the mechanical properties of coir-agave fibers reinforced polyethylene hybrid composites. Polym. Compos. 37(10), 3015–3024 (2016). https://doi.org/10.1002/PC.23498

Luo, S., Cao, J., McDonald, A.G.: Esterification of industrial lignin and its effect on the resulting poly(3-hydroxybutyrate-co-3-hydroxyvalerate) or polypropylene blends. Ind. Crops Prod. 97, 281–291 (2017). https://doi.org/10.1016/j.indcrop.2016.12.024

Acknowledgements

We acknowledge the support from (1) National Science Foundation grant number 1827364; (2) M.J. Murdock Charitable Trust for the purchase of the twin-screw extruder; (3) Margaret Zee for collecting the hop bines, (4) USDA-CSREES grant 2007-34158-17640 for support in the purchase of the DSC, and (5) Charles Olsen at Savanture LLC for providing the coupling agents.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ewurum, L., Jokic, D., Bar-Ziv, E. et al. Evaluation of the Rheological and Mechanical Properties of Mixed Plastic Waste-Based Composites. Waste Biomass Valor 13, 4625–4637 (2022). https://doi.org/10.1007/s12649-022-01794-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01794-x