Abstract

Purpose

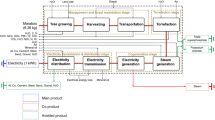

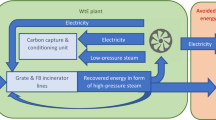

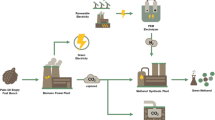

This study aims to assess environmentally three different alternatives related to the valorization of Dichrostachys cinerea tree (an invasive plant) as a feedstock for cogeneration facilities installed in the sugarcane industry in Cuba.

Methods

The Life Cycle Assessment (LCA) methodology was applied to three cogeneration alternatives: (A-1) Electricity generation using raw Dichrostachys cinerea (marabou) as fuel in a back-pressure steam turbine cycle, (A-2) Electricity generation using torrefied marabou as fuel in a back-pressure steam turbine cycle, and (A-3) Electricity generation using torrefied marabou as fuel in an extraction-condensing turbines cycle. The SimaPro software was used for the inventory modeling and the ReCiPe method (midpoint and endpoint approach) was applied to estimate the environmental impacts associated with each case.

Results and Discussion

The LCA results showed that the electricity generation from torrefied marabou using extraction-condensing turbines (A-3) reduces the environmental impacts as compared with A-1 and A-2. This performance is explained by a lower marabou relative consumption (1.85 kg marabou/kWh generated), which leads to lower emissions associated with harvesting, transportation, and pre-processing stages. Fine Particulate Matter Formation, Terrestrial Acidification, and Water Consumption accounted the worst performance for all the scenarios. Marine Ecotoxicity was the impact category with better environmental performance due to the substitution of synthetic mineral fertilizers by the ashes produced during combustion. The Human health damage category reached the higher impacts on the torrefaction subsystem in the A-3 scenario, representing over 94% of the total environmental burden of the process, causing injuries in respiratory systems. The highest beneficial impact of the cogeneration stage was associated with the consideration of residual steam as an avoided product.

Conclusions

The use of torrefied marabou in extraction-condensing steam turbines can be considered as an environmental-friendly technology in the Cuban context.

Graphical Abstract

Similar content being viewed by others

Data Availability

Not applicable.

Code Availability

Not applicable.

References

López-González, A., Domenech, B., Ferrer-Martí, L.: Sustainability evaluation of rural electrification in Cuba: from fossil fuels to modular photovoltaic systems: case studies from Sancti Spiritus Province. Energies 14(9), 2480 (2021). https://doi.org/10.3390/en14092480

ONEI Anuario estadístico de Cuba 2018: Minería y energía. Oficina Nacional de Estadística e Información, La Habana (2019)

Gutiérrez, A.S., Eras, J.J.C., Hens, L., Vandecasteele, C.: The biomass based electricity generation potential of the province of Cienfuegos, Cuba. Waste Biomass Valoriz. 8(6), 2075–2085 (2017). https://doi.org/10.1007/s12649-016-9687-x

Suarez, J.A., Beaton, P.A., Faxas, R., Luengo, C.A.: The state and prospects of renewable energy in Cuba. Energy Sour. B 11(2), 111–117 (2016). https://doi.org/10.1080/15567249.2015.1007434

Arteaga-Perez, L.E., Casas-Ledón, Y., Prins, W., Radovic, L.: Thermodynamic predictions of performance of a bagasse integrated gasification combined cycle under quasi-equilibrium conditions. Chem. Eng. J. 258, 402–411 (2014). https://doi.org/10.1016/j.cej.2014.07.104

Casas-Ledon, Y., Arteaga-Perez, L.E., Dewulf, J., Morales, M.C., Rosa, E., Peralta-Suáreza, L.M., Van Langenhove, H.: Health external costs associated to the integration of solid oxide fuel cell in a sugar–ethanol factory. Appl. Energy 113, 1283–1292 (2014). https://doi.org/10.1016/j.apenergy.2013.08.090

Gil, M.P., Moya, A.M.C., Domínguez, E.R.: Life cycle assessment of the cogeneration processes in the Cuban sugar industry. J. Clean. Prod. 41, 222–231 (2013). https://doi.org/10.1016/j.jclepro.2012.08.006

Barroso, J., Barreras, F., Amaveda, H., Lozano, A.: On the optimization of boiler efficiency using bagasse as fuel. Fuel 82(12), 1451–1463 (2003). https://doi.org/10.1016/S0016-2361(03)00061-9

Deshmukh, R., Jacobson, A., Chamberlin, C., Kammen, D.: Thermal gasification or direct combustion? Comparison of advanced cogeneration systems in the sugarcane industry. Biomass Bioenergy 55, 163–174 (2013). https://doi.org/10.1016/j.biombioe.2013.01.033

Pellegrini, L.F., de Oliveiraúnior, S., Burbano, J.C.: Supercritical steam cycles and biomass integrated gasification combined cycles for sugarcane mills. Energy 35(2), 1172–1180 (2010). https://doi.org/10.1016/j.energy.2009.06.011

Gutiérrez, A.S., Eras, J.J.C., Huisingh, D., Vandecasteele, C., Hens, L.: The current potential of low-carbon economy and biomass-based electricity in Cuba. The case of sugarcane, energy cane and marabu (Dichrostachys cinerea) as biomass sources. J. Clean. Prod. 172, 2108–2122 (2018). https://doi.org/10.1016/j.jclepro.2017.11.209

Mincex, Cuba: Cartera de oportunidades de la Inversión Extranjera 2020–2021. https://www.mincex.gob.cu/files/16563487075fd10ef409b9d5.96035972.pdf (2021). Accessed 03 Jan 2022

Fernández, M., García-Albalá, J., Andivia, E., Alaejos, J., Tapias, R., Menéndez, J.: Sickle bush (Dichrostachys cinerea L.) field performance and physical–chemical property assessment for energy purposes. Biomass Bioenergy 81, 483–489 (2015). https://doi.org/10.1016/j.biombioe.2015.08.006

Pedroso, D.T., Kaltschmitt, M.: Dichrostachys cinerea as a possible energy crop—facts and figures. Biomass Convers. Bioref. 2(1), 41–51 (2012). https://doi.org/10.1007/s13399-011-0026-y

Rudel, T.K.: Land Use and Land Use Change, Handbook of Environmental Sociology, pp. 425–438. Springer, New York (2021)

CNCT: Balance de uso y tenencia de la tierra. http://www.minag.gob.cu/sites/default/files/tractores/boletín_tierra_2017.pdf (2017). Accessed 29 Mar 2021

Martín-Casas, N., Reinoso-Pérez, M., García-Díaz, J., Hansen, H., Nielsen, M.: Evaluation of the feeding value of Dichrostachys cinerea pods for fattening pigs in Cuba. Trop. Anim. Health Prod. 49(6), 1235–1242 (2017). https://doi.org/10.1007/s11250-017-1321-9

Abreu-Naranjo, R.: Utilizacion energetica de la biomasa ligno-celulosica obtenida del Dichrostachys cinerea mediante procesos de termodescomposicion. Dipartimento di Scienze Agrarie, Alimentari e Ambientali, Universita Politecnica delle Marche, Marche (2012)

Rubio, A., Freire, M., Collado, R., Hurtado, O., Alvarado, Y., Iturria, P., González, R., Palmero D., Viera, A.: Caracterización del marabú cosechado con la máquina BMH-480, como combustible para la bioeléctrica asociada con el central Ciro Redondo de Ciego de Avila, UCLV, Santa Clara, Cuba (2019)

Ayala, K.M., Barrizonte, A.N., Viera, D.V., Dupuy, M.A.G., Rivero, C.G., Suárez, C.S., Arias, M.S.: Caracterización y alternativas de uso de la especie Dichrostachys cinerea (L.) Wight et Arm.(Marabú). Revista Forestal Baracoa 27(3), 1 (2008)

Guyat-Dupuy, M., Velázquez-Viera, D., Aguirre-Dorado, F., Capote-Pérez, V.: Características del Dichrostachys cinérea (L.) Wight et Arm. (Marabú) para la producción de carbón. Revista Forestal Baracoa 33(2), 67–72 (2014)

FAO, Charcoal production: Cuba, Food and Agricultural Organization of the United Nations. http://data.un.org/Data.aspx?d=EDATA&f=cmID%3aCH (2019). Accessed 23 Dec 2019

Alba-Reyes, Y., Pérez-Gil, M., Chong, N., Arteaga-Pérez, L.E.: Diseño de una planta de torrefacción de marabú con fines energéticos. Tecnología Química 38(1), 123–137 (2018)

Kumar, A., Cameron, J.B., Flynn, P.C.: Pipeline transport of biomass. In: Proceedings of the Twenty-Fifth Symposium on Biotechnology for Fuels and Chemicals. Breckenridge, CO, pp. 27–39. Springer, May 4–7, 2003 (2004). https://doi.org/10.1007/978-1-59259-837-3_4

Gent, S., Twedt, M., Gerometta, C., Almberg, E.: Theoretical and Applied Aspects of Biomass Torrefaction: For Biofuels and Value-Added Products. Butterworth-Heinemann, Oxford (2017)

Bergman, P.C., Boersma, A., Zwart, R., Kiel, J.: Torrefaction for Biomass Co-firing in Existing Coal-Fired Power Stations. Energy research Centre of the Netherlands, Petten (2005)

Niu, Y., Lv, Y., Lei, Y., Liu, S., Liang, Y., Wang, D.: Biomass torrefaction: properties, applications, challenges, and economy. Renew. Sustain. Energy Rev. 115, 109395 (2019). https://doi.org/10.1016/j.rser.2019.109395

Adams, P., Shirley, J., McManus, M.: Comparative cradle-to-gate life cycle assessment of wood pellet production with torrefaction. Appl. Energy 138, 367–380 (2015). https://doi.org/10.1016/j.apenergy.2014.11.002

Naranjo, R.A., Conesa, J., Pedretti, E.F., Romero, O.R.: Kinetic analysis: simultaneous modelling of pyrolysis and combustion processes of dichrostachys cinerea. Biomass Bioenergy 36, 170–175 (2012). https://doi.org/10.1016/j.biombioe.2011.10.032

Iso, I.: 14040: Environmental Management–Life Cycle Assessment–Principles and Framework. British Standards Institution, London (2006)

PRé: Simapro v_9.0.0.35. http://pre-sustainability.com/solutions/tools/simapro (2021). Accessed 01 June 2022

Huijbregts, M.A., Steinmann, Z.J., Elshout, P.M., Stam, G., Verones, F., Vieira, M., Zijp, M., Hollander, A., Van Zelm, R.: ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 22(2), 138–147 (2017). https://doi.org/10.1007/s11367-016-1246-y

Adams, P., Shirley, J., Whittaker, C., Shield, I., Darvell, L., Jones, J., McManus: Integrated assessment of the potential for torrefied wood pellets in the UK electricity market, World bioenergy 2014 conference, Jönköping, Sweden (2014)

Wang, Z., Lei, T., Yang, M., Li, Z., Qi, T., Xin, X., He, X., Ajayebi, A., Yan, X.: Life cycle environmental impacts of cornstalk briquette fuel in China. Appl. Energy 192, 83–94 (2017). https://doi.org/10.1016/j.apenergy.2017.01.071

Abreu-Naranjo, R., Crespo, Y.A., Pedretti, E.F., Conesa, J.A.: Experiments on torrefaction of Dichrostachys cinerea wood: two-level factorial design and thermogravimetric analysis. Wood Sci. Technol. 52(1), 229–243 (2018). https://doi.org/10.1007/s00226-017-0972-z

Blaser, W.J., Shanungu, G.K., Edwards, P.J., Olde Venterink, H.: Woody encroachment reduces nutrient limitation and promotes soil carbon sequestration. Ecol. Evol. 4(8), 1423–1438 (2014). https://doi.org/10.1002/ece3.1024

Alba-Reyes, Y.: Evaluación técnica, económica y ambiental de la electricidad generada a partir de pelets torrefactados de marabú en la industria azucarera, Chemical Engineering. UCLV, Santa Clara, Cuba (unpublished) (2017)

Francescato, V., Krajnc, N.: Wood Fuels Handbook. AIEL-Italian Agriforestry Energy Association, Brussels (2009)

Nguyen, T.L.T., Hermansen, J.E., Sagisaka, M.: Fossil energy savings potential of sugar cane bio-energy systems. Appl. Energy 86, S132–S139 (2009). https://doi.org/10.1016/j.apenergy.2009.05.027

Ramjeawon, T.: Life cycle assessment of electricity generation from bagasse in Mauritius. J. Clean. Prod. 16(16), 1727–1734 (2008). https://doi.org/10.1016/j.jclepro.2007.11.001

Alonso-Pippo, W., Luengo, C.A., Koehlinger, J., Garzone, P., Cornacchia, G.: Sugarcane energy use: the Cuban case. Energy Policy 36(6), 2163–2181 (2008). https://doi.org/10.1016/j.enpol.2008.02.025

Pérez-Gil, M.: Modelación de los inventarios parametrizados del azúcar crudo en Cuba para la evaluación ambiental con enfoque de ciclo de vida. Chemical Engineering, UCLV, Santa Clara, Cuba (2016)

Bosch, O.N., Ruiz, L.O.: Estudio termoeconómico de sistemas de cogeneración para un central azucarero. Potencia 70(92), 81 (2009)

Espinosa, R., Machado, S., Reymond, A., Carrillo, M., Priadko, N.: Sistemas de utilización del calor en la industria azucarera, La Habana. Informe sobre las Calderas, Ingenio San Carlos (1990)

Baloh, A., Wittwer, E.: Energy Manual for Sugar Factories. Bartens, Belin (1995)

Rein, P.: Cane Sugar Engineering. Verlag Dr, Albert Bartens KG (2016)

Bergman, P.C., Kiel, J.H.: Torrefaction for biomass upgrading. In: Proceedings of the 14th European Biomass Conference.sn, pp. 17–21. Paris, France (2005)

Nunes, L., Matias, J., Catalão, J.: A review on torrefied biomass pellets as a sustainable alternative to coal in power generation. Renew. Sustain. Energy Rev. 40, 153–160 (2014). https://doi.org/10.1016/j.rser.2014.07.181

Arteaga-Pérez, L.E., Grandón, H., Flores, M., Segura, C., Kelley, S.S.: Steam torrefaction of Eucalyptus globulus for producing black pellets: a pilot-scale experience. Bioresour. Technol. 238, 194–204 (2017). https://doi.org/10.1016/j.biortech.2017.04.037

Huang, Y.-F., Cheng, P.-H., Chiueh, P.-T., Lo, S.-L.: Leucaena biochar produced by microwave torrefaction: fuel properties and energy efficiency. Appl. Energy 204, 1018–1025 (2017). https://doi.org/10.1016/j.apenergy.2017.03.007

Zhang, C., Ho, S.-H., Chen, W.-H., Xie, Y., Liu, Z., Chang, J.-S.: Torrefaction performance and energy usage of biomass wastes and their correlations with torrefaction severity index. Appl. Energy 220, 598–604 (2018). https://doi.org/10.1016/j.apenergy.2018.03.129

Shoulaifar, T.K.: Chemical changes in biomass during torrefaction (2016)

Pang, S., Mujumdar, A.S.: Drying of woody biomass for bioenergy: Drying technologies and optimization for an integrated bioenergy plant. Dry. Technol. 28(5), 690–701 (2010). https://doi.org/10.1080/07373931003799236

Arteaga-Pérez, L.E., Vega, M., Rodríguez, L.C., Flores, M., Zaror, C.A., Ledón, Y.C.: Life-Cycle Assessment of coal–biomass based electricity in Chile: focus on using raw vs torrefied wood. Energy Sustain. Dev. 29, 81–90 (2015). https://doi.org/10.1016/j.esd.2015.10.004

Sarker, T.R., Nanda, S., Dalai, A.K., Meda, V.: A review of torrefaction technology for upgrading lignocellulosic biomass to solid biofuels. BioEnergy Res. 14, 1–25 (2021). https://doi.org/10.1007/s12155-020-10236-2

Gaitán-Alvarez, J., Moya, R., Puente-Urbina, A., Rodriguez-Zuñiga, A.: Physical and compression properties of pellets manufactured with the biomass of five woody tropical species of Costa Rica torrefied at different temperatures and times. Energies 10(8), 1205 (2017). https://doi.org/10.3390/en10081205

Tumuluru, J.S., Wright, C.T., Hess, J.R., Kenney, K.L.: A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Bioref. 5(6), 683–707 (2011). https://doi.org/10.1002/bbb.324

Obernberger, I., Thek, G.: Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 27(6), 653–669 (2004). https://doi.org/10.1016/j.biombioe.2003.07.006

Kamate, S., Gangavati, P.: Exergy analysis of cogeneration power plants in sugar industries. Appl. Therm. Eng. 29(5–6), 1187–1194 (2009). https://doi.org/10.1016/j.applthermaleng.2008.06.016

Mbohwa, C.: Bagasse energy cogeneration potential in the Zimbabwean sugar industry. Renew. Energy 28(2), 191–204 (2003). https://doi.org/10.1016/S0960-1481(02)00023-X

Mbohwa, C., Fukuda, S.: Electricity from bagasse in Zimbabwe. Biomass Bioenergy 25(2), 197–207 (2003). https://doi.org/10.1016/S0961-9534(03)00011-4

Rubio-González, A., Rubio Rodríguez, M., Roque Díaz, P.: Valoración técnica y económica para el incremento de los parámetros del vapor en ingenios azucareros cubanos. Centro Azúcar 45(3), 24–31 (2018)

Río, Y.: Perspectivas de generación eléctrica de la Empresa Azucarera de Villa Clara en el 2030 y vías para su incremento. Mechanical Engineering, UCLV, Santa Clara, Cuba (2017)

Albuquerque, A.R., Angélica, R.S., Merino, A., Paz, S.P.: Chemical and mineralogical characterization and potential use of ash from Amazonian biomasses as an agricultural fertilizer and for soil amendment. J. Clean. Prod. 295, 126472 (2021). https://doi.org/10.1016/j.clepro.2021.126472

Prinoth: Biomass harvester. The next generation. BMH 480 with H1600 attachment. https://www.prinoth.com/en/vegetation-management/products/biomass-harvesting/bmh-480-130/ (2020). Accessed 01 May 2021

EPA, TIER 4 Interim EPA Emissions Requirements for Diesel Generators Sets. Caterpillar. www.cat.com (2010). Accessed 20 Mar 2019

Lakshminarayanan, P., Agarwal, A.K.: Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, New York (2019)

EPA: Nonroad Compression-Ignition Engines: Exhaust Emission Standards. https://nepis.epa.gov/Exe/ZyPDF.cgi?Dockey=P100OA05.pdf (2016). Accessed 20 Mar 2019

Caterpillar, Cat® C15 ACERT™ Diesel Engine. https://emc.cat.com/pubdirect.ashx?media_string_id=SS-7144002-18375173-001.pdf (2017). Accessed 20 Mar 2019

Bonzon, G.B, García, S.F., Avila, J.M.: Análisis técnico económico de los vehículos que circulan en Cuba y la reposición del parque, Ciencia en su PC (1) (2005)

Clean-Air-Institute: Metodologías para la estimación de emisiones de transporte urbano de carga y guías para la recopilación y organización de datos. Washington DC (2013)

Basu, P.: Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory. Academic press, Cambridge (2018)

Johnson, K.G., Mollenhauer, K., Tschöke, H.: Handbook of Diesel Engines. Springer Science & Business Media, New York (2010)

Farhat, O., Faraj, J., Hachem, F., Castelain, C., Khaled, M.: A recent review on waste heat recovery methodologies and applications: comprehensive review, critical analysis and potential recommendations. Clean. Eng. Technol. 6, 100387 (2022). https://doi.org/10.1016/j.clet.2021.100387

Koppejan, J., Van Loo, S.: The Handbook of Biomass Combustion and Co-Firing. Routledge, London (2012)

Havukainen, J., Nguyen, M.T., Väisänen, S., Horttanainen, M.: Life cycle assessment of small-scale combined heat and power plant: environmental impacts of different forest biofuels and replacing district heat produced from natural gas. J. Clean. Prod. 172, 837–846 (2018). https://doi.org/10.1016/j.jclepro.2017.10.241

Silva, D.A.D., Eloy, E., Caron, B.O., Trugilho, P.F.: Elemental chemical composition of forest biomass at different ages for energy purposes. Floresta e Ambiente 26, 2019 (2019). https://doi.org/10.1590/2179-8087.020116

Saxena, R., Adhikari, D., Goyal, H.: Biomass-based energy fuel through biochemical routes: a review. Renew. Sustain. Energy Rev. 13(1), 167–178 (2009). https://doi.org/10.1016/j.rser.2007.07.011

Chen, W.-H., Lu, K.-M., Tsai, C.-M.: An experimental analysis on property and structure variations of agricultural wastes undergoing torrefaction. Appl. Energy 100, 318–325 (2012). https://doi.org/10.1016/j.apenergy.2012.05.056

Greaver, T.L., Sullivan, T.J., Herrick, J.D., Barber, M.C., Baron, J.S., Cosby, B.J., Deerhake, M.E., Dennis, R.L., Dubois, J.-J.B., Goodale, C.L.: Ecological effects of nitrogen and sulfur air pollution in the US: what do we know? Front. Ecol. Environ. 10(7), 365–372 (2012). https://doi.org/10.1890/110049

Pardo, L.H., Fenn, M.E., Goodale, C.L., Geiser, L.H., Driscoll, C.T., Allen, E.B., Baron, J.S., Bobbink, R., Bowman, W.D., Clark, C.M.: Effects of nitrogen deposition and empirical nitrogen critical loads for ecoregions of the United States. Ecol. Appl. 21(8), 3049–3082 (2011). https://doi.org/10.1890/10-2341.1

Xu, X., Huo, S., Weng, N., Zhang, H., Ma, C., Zhang, J., Wu, F.: Effects of sulfide availability on the metabolic activity and population dynamics of cable bacteria in freshwater sediment. Sci. Total Environ. 808, 151817 (2022). https://doi.org/10.1016/j.scitotenv.2021.1518.17

Corona, B., Shen, L., Sommersacher, P., Junginger, M.: Consequential Life Cycle Assessment of energy generation from waste wood and forest residues: the effect of resource-efficient additives. J. Clean. Prod. 259, 120948 (2020). https://doi.org/10.1016/j.clepro.2020.120948

Renó, M.L.G., Lora, E.E.S., Palacio, J.C.E., Venturini, O.J., Buchgeister, J., Almazan, O.: A LCA (life cycle assessment) of the methanol production from sugarcane bagasse. Energy 36(6), 3716–3726 (2011). https://doi.org/10.1016/j.energy.2010.12.010

Feng, Q., Wang, B., Chen, M., Wu, P., Lee, X., Xing, Y.J.R.: Invasive plants as potential sustainable feedstocks for biochar production and multiple applications: a review. Resour. Conserv. Recycl. 164, 105204 (2021). https://doi.org/10.1016/j.resconrec.2020.105204

Kulig, B., Gacek, E., Wojciechowski, R., Oleksy, A., Kołodziejczyk, M., Szewczyk, W., Klimek-Kopyra, A.: Biomass yield and energy efficiency of willow depending on cultivar, harvesting frequency and planting density. Plant Soil Environ. 65(8), 377–386 (2019). https://doi.org/10.17221/594/2018-PSE

Sileshi, G.W., Mafongoya, P., Akinnifesi, F., Phiri, E., Chirwa, P., Beedy, T., Makumba, W., Nyamadzawo, G., Wuta, M., Nyamugafata, P.: Agroforestry: Fertilizer Trees. Elsevier, Amsterdam (2014)

Fuwape, J.A., Akindele, S.O.: Biomass yield and energy value of some fast-growing multipurpose trees in Nigeria. Biomass Bioenergy 12(2), 101–106 (1997). https://doi.org/10.1016/S0961-9534(96)00061-X

Lázaro-Lobo, A., Lucardi, R.D., Ramirez-Reyes, C., Ervin, G.N.: Management, Region-wide assessment of fine-scale associations between invasive plants and forest regeneration. For. Ecol. Manag. 483, 118930 (2021). https://doi.org/10.1016/j.foreco.2021.118930

Chandrasekaran, A., Subbiah, S., Bartocci, P., Yang, H., Fantozzi, F.: Carbonization using an Improved Natural Draft Retort Reactor in India: comparison between the performance of two woody biomasses Prosopis juliflora and Casuarina equisetifolia. Fuel 285, 119095 (2021). https://doi.org/10.1016/j.fuel.2020.119095

Helin, T., Holma, A., Soimakallio, S.: Is land use impact assessment in LCA applicable for forest biomass value chains? Findings from comparison of use of Scandinavian wood, agro-biomass and peat for energy. Int. J. Life Cycle Assess. 19(4), 770–785 (2014). https://doi.org/10.1007/s11367-014-0706-5

McNamee, P., Adams, P., McManus, M., Dooley, B., Darvell, L., Williams, A., Jones, J.: An assessment of the torrefaction of North American pine and life cycle greenhouse gas emissions. Energy Convers. Manag. 113, 177–188 (2016). https://doi.org/10.1016/j.enconman.2016.01.006

Silva, D.A.L., Delai, I., Montes, M.L.D., Ometto, A.R.: Life cycle assessment of the sugarcane bagasse electricity generation in Brazil. Renew. Sustain. Energy Rev. 32, 532–547 (2014). https://doi.org/10.1016/j.rser.2013.12.056

Hiloidhari, M., Banerjee, R., Rao, A.B.: Life cycle assessment of sugar and electricity production under different sugarcane cultivation and cogeneration scenarios in India. J. Clean. Prod. 290, 125170 (2021). https://doi.org/10.1016/j.jclepro.2020.125170

Guerra, J.P.M., Coleta, J.R., Arruda, L.C.M., Silva, G.A., Kulay, L.: Comparative analysis of electricity cogeneration scenarios in sugarcane production by LCA. Int. J. Life Cycle Assess. 19(4), 814–825 (2014). https://doi.org/10.1007/s11367-014-0702-9

Qian, Y., Yu, L., Li, Z., Zhang, Y., Xu, L., Zhou, Q., Han, D., Lu, X.: A new methodology for diesel surrogate fuel formulation: bridging fuel fundamental properties and real engine combustion characteristics. Energy 148, 424–447 (2018). https://doi.org/10.1016/j.energy.2018.01.181

Proto, A.R., Bacenetti, J., Macri, G., Zimbalatti, G.: Roundwood and bioenergy production from forestry: environmental impact assessment considering different logging systems. J. Clean. Prod. 165, 1485–1498 (2017). https://doi.org/10.1016/j.jclepro.2017.07.227

Simões Amaral, S., Andrade de Carvalho, J., Martins Costa, M.A., Pinheiro, C.: Particulate matter emission factors for biomass combustion. Atmosphere 7(11), 141 (2016). https://doi.org/10.3390/atmos7110141

Caserini, S., Livio, S., Giugliano, M., Grosso, M., Rigamonti, L.: LCA of domestic and centralized biomass combustion: the case of Lombardy (Italy). Biomass Bioenergy 34(4), 474–482 (2010). https://doi.org/10.1016/j.biombioe.2009.12.011

Mitchell, E., Lea-Langton, A., Jones, J., Williams, A., Layden, P., Johnson, R.: The impact of fuel properties on the emissions from the combustion of biomass and other solid fuels in a fixed bed domestic stove. Fuel Process. Technol. 142, 115–123 (2016). https://doi.org/10.1016/j.fuproc.2015.09.031

Maxwell, D., Gudka, B., Jones, J., Williams, A.: Emissions from the combustion of torrefied and raw biomass fuels in a domestic heating stove. Fuel Process. Technol. 199, 106266 (2020). https://doi.org/10.1016/j.fuproc.2019.106266

Acknowledgements

The authors acknowledge the CEEPI for the financial support and to the Universidad Central de Las Villas for providing access to the SimaPro software and its related databases, and project ANID/FONDAP/15130015.

Funding

The authors acknowledge the financial support of the Cuban Program ´´Sustainable Development of the Energy Renewable Resources´´, project P211 LH003068 (Bioconversion of agro-industrial waste leaching in high-efficiency reactors).

Author information

Authors and Affiliations

Contributions

YA: Investigation-writing-original draft preparation. MP: Writing-original draft preparation-supervision-reviewing. ELB: Writing-reviewing. YC: Supervision-reviewing. LEA: Conceptualization-supervision-reviewing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alba-Reyes, Y., Pérez-Gil, M., Barrera, E.L. et al. Comparison of Raw and Torrefied Dichrostachys cinerea as a Fuel for Cogeneration Systems: A Life Cycle Assessment. Waste Biomass Valor 13, 3653–3669 (2022). https://doi.org/10.1007/s12649-022-01746-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01746-5