Abstract

In this study, the combined strategy of using high solid load, on-site enzyme cocktails and surfactant was evaluated in saccharifications of hydrothermally pretreated sugarcane bagasse (HP-SB) and ethanol production. The hydrolyses were carried in fed-batch mode with a solid load of 10–40% (w/v) at time intervals of 12 h, using two homemade enzyme extracts (ES1 from Aspergillus niger monoculture and ES2 from A. niger, Trametes versicolor and Pleurotus ostreatus consortium), 10 FPU/gds of cellulase loading at 50 °C for 72 h. After optimization of solid loading, new saccharifications were performed with the addition of 5% (w/v) surfactant (Triton X-100). The HP of SB led to a significant reduction of 69.26% in hemicelluloses content, but also preserved the cellulose fraction in HP-SB. The increase of HP-SB load in hydrolysis from 10 to 35% significantly improved the release of total reducing sugars (TRS), with an increase of 188.54% in ES1 and 177.46% in ES2. The use of Triton X-100 in saccharifications of HP-SB (30% w/v) also positively contributed to TRS production, with an increase in TRS of 6.22% in ES1S and 24% in ES2S. The fermentation of the hydrolysate after surfactant-assisted hydrolysis of HP-SB (30% w/v) led to an ethanol yield of 81.70% for F1S and 88.03% for F2S. Results demonstrated that the integrated use of high solid load, low-cost on-site enzyme cocktail and surfactant (Triton X-100) can be a promising approach to improve the efficiency of bioconversion of lignocellulosic biomass to fermentable sugars.

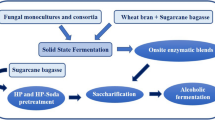

Graphical Abstract

Similar content being viewed by others

Change history

10 February 2022

the article title is updated

References

Rodrigues, PdeO., Pereira, JdeC., Santos, D.Q., dos, Gurgel, L.V.A., Pasquini, D., Baffi, M.A.: Synergistic action of an Aspergillus (hemi-) cellulolytic consortium on sugarcane bagasse saccharification. Ind. Crops Prod. 109, 173–181 (2017). https://doi.org/10.1016/j.indcrop.2017.08.031

Travaini, R., Martín-Juárez, J., Lorenzo-Hernando, A., Bolado-Rodríguez, S.: Ozonolysis: an advantageous pretreatment for lignocellulosic biomass revisited. Bioresour. Technol. 199, 2–12 (2016). https://doi.org/10.1016/j.biortech.2015.08.143

Rodrigues, P., de O., Barreto, Brandão, EdaS., Gurgel, R.L., Pasquini, L.V.A., Baffi, D.: M.A.: On-site produced enzyme cocktails for saccharification and ethanol production from sugarcane bagasse fractionated by hydrothermal and alkaline pretreatments. Waste Biomass Valorization (2021). https://doi.org/10.1007/s12649-021-01499-7

Bittencourt, G.A., Barreto, EdaS., Brandão, R.L., Baêta, B.E.L., Gurgel, L.V.A.: Fractionation of sugarcane bagasse using hydrothermal and advanced oxidative pretreatments for bioethanol and biogas production in lignocellulose biorefineries. Bioresour. Technol. 292, 121963 (2019). https://doi.org/10.1016/j.biortech.2019.121963

Dos Santos, B.S.L., Gomes, A.F.S., Franciscon, E.G., De Oliveira, J.M., Baffi, M.A.: Thermotolerant and mesophylic fungi from sugarcane bagasse and their prospection for biomass-degrading enzyme production. Braz. J. Microbiol. 46, 903–910 (2015). https://doi.org/10.1590/S1517-838246320140393

Hernández-Beltrán, J.U., Hernández-Escoto, H.: Enzymatic hydrolysis of biomass at high-solids loadings through fed-batch operation. Biomass Bioenergy 119, 191–197 (2018). https://doi.org/10.1016/j.biombioe.2018.09.020

Zhao, X., Dong, L., Chen, L., Liu, D.: Batch and multi-step fed-batch enzymatic saccharification of Formiline-pretreated sugarcane bagasse at high solid loadings for high sugar and ethanol titers. Bioresour. Technol. 135, 350–356 (2013). https://doi.org/10.1016/j.biortech.2012.09.074

Paulova, L., Patakova, P., Branska, B., Rychtera, M., Melzoch, K.: Lignocellulosic ethanol: technology design and its impact on process efficiency. Biotechnol. Adv. 33, 1091–1107 (2015). https://doi.org/10.1016/j.biotechadv.2014.12.002

Gatt, E., Khatri, V., Bley, J., Barnabé, S., Vandenbossche, V., Beauregard, M.: Enzymatic hydrolysis of corn crop residues with high solid loadings: new insights into the impact of bioextrusion on biomass deconstruction using carbohydrate-binding modules. Bioresour. Technol. 282, 398–406 (2019). https://doi.org/10.1016/j.biortech.2019.03.045

Raj, K., Krishnan, C.: Improved high solid loading enzymatic hydrolysis of low-temperature aqueous ammonia soaked sugarcane bagasse using laccase-mediator system and high concentration ethanol production. Ind. Crops Prod. 131, 32–40 (2019). https://doi.org/10.1016/j.indcrop.2019.01.032

Liu, Z.H., Chen, H.Z.: Periodic peristalsis enhancing the high solids enzymatic hydrolysis performance of steam exploded corn stover biomass. Biomass Bioenergy 93, 13–24 (2016). https://doi.org/10.1016/j.biombioe.2016.06.022

Sotaniemi, V.H., Taskila, S., Ojamo, H., Tanskanen, J.: Controlled feeding of lignocellulosic substrate enhances the performance of fed-batch enzymatic hydrolysis in a stirred tank reactor. Biomass Bioenergy 91, 271–277 (2016). https://doi.org/10.1016/j.biombioe.2016.05.037

Kim, D.H., Park, H.M., Jung, Y.H., Sukyai, P., Kim, K.H.: Pretreatment and enzymatic saccharification of oak at high solids loadings to obtain high titers and high yields of sugars. Bioresour. Technol. 284, 391–397 (2019). https://doi.org/10.1016/j.biortech.2019.03.134

Liu, Y., Xu, J., Zhang, Y., Yuan, Z., Xie, J.: Optimization of high solids fed-batch saccharification of sugarcane bagasse based on system viscosity changes. J. Biotechnol. 211, 5–9 (2015). https://doi.org/10.1016/j.jbiotec.2015.06.422

Wanderley, M.C., de A., Martín, Rocha, C., G.J. de M., Gouveia: E.R.: Increase in ethanol production from sugarcane bagasse based on combined pretreatments and fed-batch enzymatic hydrolysis. Bioresour. Technol. 128, 448–453 (2013). https://doi.org/10.1016/j.biortech.2012.10.131

de Oliveira Rodrigues, P., Gurgel, L.V.A., Pasquini, D., Badotti, F., Góes-Neto, A., Baffi, M.A.: Lignocellulose-degrading enzymes production by solid-state fermentation through fungal consortium among Ascomycetes and Basidiomycetes. Renew. Energy. 145, 2683–2693 (2020). https://doi.org/10.1016/j.renene.2019.08.041

Pereira Scarpa, JdeC., Marques, P., Monteiro, N.Alves, Martins, D., Paula, G.M., de Boscolo, A.V., da Silva, M., Gomes, R., Bocchini, E.Alonso: D.: Saccharification of pretreated sugarcane bagasse using enzymes solution from Pycnoporus sanguineus MCA 16 and cellulosic ethanol production. Ind. Crops Prod. 141, 111795 (2019). https://doi.org/10.1016/j.indcrop.2019.111795

dos Santos, B.V., Rodrigues, P., de O., Albuquerque, Pasquini, C.J.B., Baffi, D.: M.A.: Use of an (hemi) cellulolytic enzymatic extract produced by Aspergilli species consortium in the saccharification of biomass sorghum Appl. Biochem. Biotech. 189(1), 37–48 (2019). https://doi.org/10.1007/s12010-019-02991-6

Alhammad, A., Adewale, P., Kuttiraja, M., Christopher, L.P.: Enhancing enzyme-aided production of fermentable sugars from poplar pulp in the presence of non-ionic surfactants. Bioprocess. Biosyst. Eng. 41, 1133–1142 (2018). https://doi.org/10.1007/s00449-018-1942-z

Li, Y., Sun, Z., Ge, X., Zhang, J.: Effects of lignin and surfactant on adsorption and hydrolysis of cellulases on cellulose. Biotechnol. Biofuels. 9, 20 (2016). https://doi.org/10.1186/s13068-016-0434-0

Vignesh, N., Chandraraj, K.: Improved high solids loading enzymatic hydrolysis and fermentation of cotton microdust by surfactant addition and optimization of pretreatment. Process Biochem. 106, 60–69 (2021). https://doi.org/10.1016/j.procbio.2021.04.002.

Baêta, B.E.L., Lima, D.R.S., Filho, J.G.B., Adarme, O.F.H., Gurgel, L.V.A., de Aquino, S.F.: Evaluation of hydrogen and methane production from sugarcane bagasse hemicellulose hydrolysates by two-stage anaerobic digestion process. Bioresour. Technol. 218, 436–446 (2016). https://doi.org/10.1016/j.biortech.2016.06.113

Miller, G.L.: Use of dinitrosaiicyiic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959). https://doi.org/10.1021/ac60147a030

Santos, L.D., Sousa, M.D.B., Guidini, C.Z., De Resende, M.M., Cardoso, V.L., Ribeiro, E.J.: Continuous ethanol fermentation in tower reactors with cell recycling using flocculent Saccharomyces cerevisiae. Process Biochem. 50, 1725–1729 (2015). https://doi.org/10.1016/j.procbio.2015.07.020

Lima, D.R.S., Adarme, O.F.H., Baêta, B.E.L., Gurgel, L.V.A., de Aquino, S.F.: Influence of different thermal pretreatments and inoculum selection on the biomethanation of sugarcane bagasse by solid-state anaerobic digestion: a kinetic analysis. Ind. Crops Prod. 111, 684–693 (2018). https://doi.org/10.1016/j.indcrop.2017.11.048

Moreira, F.S., Machado, R.G., Romão, B.B., Batista, F.R.X., Ferreira, J.S., Cardoso, V.L.: Improvement of hydrogen production by biological route using repeated batch cycles. Process Biochem. 58, 60–68 (2017). https://doi.org/10.1016/j.procbio.2017.04.013

Vallejos, M.E., Zambon, M.D., Area, M.C., Curvelo, A.A.S.: Influence of the chemical composition on the enzymatic hydrolysis of hot water and organosolv pretreated sugarcane bagasse. Waste Biomass Valorization 11, 3337–3344 (2019). https://doi.org/10.1007/s12649-019-00657-2

de Carvalho, D.M., Sevastyanova, O., Penna, L.S., Silva, B.P. da, Lindström, M.E., Colodette, J.L.: Assessment of chemical transformations in eucalyptus, sugarcane bagasse and straw during hydrothermal, dilute acid and alkaline pretreatments. Ind. Crops Prod. 73, 118–126: (2015). https://doi.org/10.1016/j.indcrop.2015.04.021

Modenbach, A.A., Nokes, S.E.: Enzymatic hydrolysis of biomass at high-solids loadings—a review. Biomass Bioenergy 56, 526–544 (2013). https://doi.org/10.1016/j.biombioe.2013.05.031

Nelson, D.L., Cox, M.M.: Lehninger Principles of Biochemistry, 6th edn. W.H. Freeman, New York (2012)

Zain, M.M., Mohammad, A.W., Harun, S., Fauzi, N.A., Hairom, N.H.H.: Synergistic effects on process parameters to enhance enzymatic hydrolysis of alkaline oil palm fronds. Ind. Crops Prod. 122, 617–626 (2018). https://doi.org/10.1016/j.indcrop.2018.06.037

Kristensen, J.B., Felby, C., Jørgensen, H.: Yield-determining factors in high-solids enzymatic hydrolysis of lignocellulose. Biotechnol. Biofuels. 2, 1–10 (2009). https://doi.org/10.1186/1754-6834-2-11

Wikandari, R., Sanjaya, A.P., Millati, R., Karimi, K., Taherzadeh, M.J.: Fermentation Inhibitors in Ethanol and Biogas Processes and Strategies to Counteract Their Effects. Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels. Elsevier Inc., pp. 461–499. (2019) https://doi.org/10.1016/b978-0-12-816856-1.00020-8

Verma, N., Kumar, V., Bansal, M.C.: Valorization of waste biomass in fermentative production of cellulases: a review. Waste Biomass Valorization 12(2), 613–640 (2020). https://doi.org/10.1007/s12649-020-01048-8

Devi, A., Niazi, A., Ramteke, M., Sreedevi, U.: Techno-economic analysis of ethanol production from lignocellulosic biomass—a comparison of fermentation, thermo catalytic, and chemocatalytic technologies. Bioprocess. Biosyst. Eng. 44, 1093–1107 (2021). https://doi.org/10.1007/s00449-020-02504-4

Acknowledgements

The authors are grateful to the Federal University of Uberlandia (UFU) and the Federal University of Ouro Preto (UFOP) for the technical support. This study was financed by Minas Gerais State Research Funding Agency (FAPEMIG grant numbers APQ-01360-14 and CEX-PPM-00645-17). The authors would also like to thank the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES), the Brazilian National Council for Scientific and Technological Development (CNPq) and the Brazilian Study and Project Funding Agency (FINEP) for funding this research. Patrísia de Oliveira Rodrigues is grateful to FAPEMIG for her Doctorate fellowship.

Author information

Authors and Affiliations

Contributions

POR: conceptualization, methodology, validation, formal analysis, investigation, writing—original draft and editing. FSM, VLC and LDS: methodology, validation, formal analysis. LVAG: methodology, formal analysis, resources, writing review. DP: methodology, formal analysis, resources, writing review, funding acquisition. MAB: conceptualization, methodology, formal analysis, resources, writing review & editing, supervision, project administration, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors report no declaration of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article is revised: the article title is updated.

Rights and permissions

About this article

Cite this article

de Oliveira Rodrigues, P., Moreira, F.S., Cardoso, V.L. et al. Combination of High Solid Load, On-site Enzyme Cocktails and Surfactant in the hydrolysis of Hydrothermally Pretreated Sugarcane Bagasse and Ethanol Production. Waste Biomass Valor 13, 3085–3094 (2022). https://doi.org/10.1007/s12649-022-01685-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01685-1