Abstract

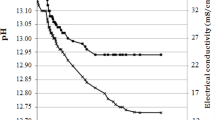

We describe herein a detailed study on the effect of molar ratio MR = n(OH−)/n(Ca2+) on the Phosphogypsum (PG) waste ammonia-carbonation process. The use of an aqueous NH3 solution/gaseous CO2 mixture as an alternative and environmental medium compared with other mediums [(NH4)2CO3 for example] is proposed for CO2 capture and PG recycling. The main purity, reaction time, and production efficiency of the obtained products were systematically studied for the different molar ratios using several physicochemical techniques: XRD, XRF, FTIR, SEM/EDX, pH, and electrical conductivity meters. For economic reasons, the molar ratio was varied to obtain values close to those of the stoichiometry, MR (2 ≤ MR ≤ 4). The obtained results show that the MR presents an important effect on the conversion process. In parallel, a comparative study between the conversion process of the synthetic gypsum (SG) and PG shows that the two samples are similar. All these findings revealed that PG waste could be used as a substituent to the SG in the general application of this last useful product.

Graphic Abstract

Similar content being viewed by others

References

Anfar, Z., et al.: Technology Recent trends on numerical investigations of response surface methodology for pollutants adsorption onto activated carbon materials: a review surface methodology for pollutants adsorption onto. Crit. Rev. Environ. Sci. Technol. (2019). https://doi.org/10.1080/10643389.2019.1642835

Bouargane, B., et al.: Experimental investigation of the effects of synthesis parameters on the precipitation of calcium carbonate and Portlandite from Moroccan phosphogypsum and pure gypsum using carbonation route. Waste Biomass Valoriz. (2020). https://doi.org/10.1007/s12649-019-00923-3

Pérez-Moreno, S.M., Gázquez, M.J., Pérez-López, R., Vioque, I., Bolívar, J.P.: Assessment of natural radionuclides mobility in a phosphogypsum disposal area. Chemosphere 211, 775–783 (2018). https://doi.org/10.1016/j.chemosphere.2018.07.193

Cuadri, A.A., Pérez-Moreno, S., Altamar, C.L., Navarro, F.J., Bolívar, J.P.: Phosphogypsum as additive for foamed bitumen manufacturing used in asphalt paving. J. Clean. Prod. (2021). https://doi.org/10.1016/j.jclepro.2020.124661

Harrou, A., Gharibi, E.K., Taha, Y., Fagel, N., El Ouahabi, M.: Phosphogypsum and black steel slag as additives for ecological bentonite-based materials: microstructure and characterization. Minerals 10(12), 1–16 (2020). https://doi.org/10.3390/min10121067

Wang, J., et al.: A novel method for purification of phosphogypsum. Physicochem. Probl. Miner. Process. 56(5), 975–983 (2020). https://doi.org/10.37190/PPMP/127854

Ma, B., Jin, Z., Su, Y., Lu, W., Qi, H., Hu, P.: Utilization of hemihydrate phosphogypsum for the preparation of porous sound absorbing material. Constr. Build. Mater. 234, 117346 (2020). https://doi.org/10.1016/j.conbuildmat.2019.117346

Torres-Sánchez, R., Sánchez-Rodas, D., de la Campa, A.M.S., Kandler, K., Schneiders, K., de la Rosa, J.D.: Geochemistry and source contribution of fugitive phosphogypsum particles in Huelva, (SW Spain). Atmos. Res. 230, 1–11 (2019). https://doi.org/10.1016/j.atmosres.2019.104650

Burnett, W.C., Elzerman, A.W.: Nuclide migration and the environmental radiochemistry of Florida phosphogypsum. J. Environ. Radioact. 54(1), 27–51 (2001). https://doi.org/10.1016/S0265-931X(00)00164-8

Burnett, W.C., Schultz, M.K., Hull, C.D.: Radionuclide flow during the conversion of phosphogypsum to ammonium sulfate. J. Environ. Radioact. 32(1–2), 33–51 (1996). https://doi.org/10.1016/0265-931X(95)00078-O

Tayibi, H., Choura, M., López, F.A., Alguacil, F.J., López-Delgado, A.: Environmental impact and management of phosphogypsum. J. Environ. Manage. 90(8), 2377–2386 (2009). https://doi.org/10.1016/j.jenvman.2009.03.007

Bchitou, R., Hamad, M., Lacout, J.L., Ferhat, M.: Effets du cadmium sur la formation du phosphogypse lors de la production de l’acide phosphorique. Phosphorus, Sulfur Silicon Relat Elem. 139, 147–162 (1998). https://doi.org/10.1080/10426509808035684

Villalón, I., Viktoras, F., Danutė, D., Dalia, V.: The investigation of phosphogypsum specimens processed by press—forming method. Waste and Biomass Valoriz. (2020). https://doi.org/10.1007/s12649-020-01067-5

Bouargane, B., et al.: Recovery of Ca(OH)2, CaCO3 and Na2SO4 from Moroccan phosphogypsum waste. J. Mater. Cycles Waste Manag. 21, 1563–1571 (2019). https://doi.org/10.1007/s10163-019-00910-9

Altiner, M.: Effect of alkaline types on the production of calcium carbonate particles from gypsum waste for fixation of CO2 by mineral carbonation. Int. J. Coal Prep. Util. 39(3), 113–131 (2019). https://doi.org/10.1080/19392699.2018.1452739

Kandil, A.-H.T., Cheira, M.F., Gado, H.S., Soliman, M.H., Akl, H.M.: Ammonium sulfate preparation from phosphogypsum waste. J. Radiat. Res. Appl. Sci. 10(1), 24–33 (2017). https://doi.org/10.1016/j.jrras.2016.11.001

Lu, S.Q., Lan, P.Q., Wu, S.F.: Preparation of nano-CaCO3 from phosphogypsum by gas-liquid-solid reaction for CO2 sorption. Ind. Eng. Chem. Res. 55(38), 10172–10177 (2016). https://doi.org/10.1021/acs.iecr.6b02551

Cárdenas-Escudero, C., Morales-Flórez, V., Pérez-López, R., Santos, A., Esquivias, L.: Procedure to use phosphogypsum industrial waste for mineral CO2 sequestration. J. Hazard. Mater. 196, 431–435 (2011). https://doi.org/10.1016/j.jhazmat.2011.09.039

Biyoune, M.G., et al.: Water quality depends on remineralization’s method in the desalination plant. Mediterr. J. Chem. 10(2), 162–170 (2020). https://doi.org/10.13171/mjc10202002141228mgb

Douahem, H., Hammi, H.A., Hamzaoui, H., Nif, A.M.: A preliminary study of phosphogypsum transformation into calcium fluoride. J. Tun. Chem. Soc. 19, 147–151 (2017). https://doi.org/10.1080/120589642.2017.44568992

Larsen, M.J., Jensen, S.J.: Experiments on the initiation of calcium fluoride formation with reference to the solubility of dental enamel and Brushite. Arch. Oral Biol. 39(1), 23–27 (1994). https://doi.org/10.1016/0003-9969(94)90030-2

Kawano, N., Nakauchi, D., Fukuda, K., Okada, G., Kawaguchi, N., Yanagida, T.: Comparative study of scintillation and dosimetric properties between Tm-doped CaF2 translucent ceramic and single crystal. Jpn. J. Appl. Phys. 57(10), 1–4 (2018). https://doi.org/10.7567/JJAP.57.102401

Eloneva, S., Teir, S., Salminen, J., Fogelholm, C.J., Zevenhoven, R.: Steel converter slag as a raw material for precipitation of pure calcium carbonate. Ind. Eng. Chem. Res. 47(18), 7104–7111 (2008). https://doi.org/10.1021/ie8004034

Han, Y.S., Hadiko, G., Fuji, M., Takahashi, M.: Influence of initial CaCl2 concentration on the phase and morphology of CaCO3 prepared by carbonation. J. Mater. Sci. 41(14), 4663–4667 (2006). https://doi.org/10.1007/s10853-006-0037-4

Msila, X., Billing, D.G., Barnard, W.: Capture and storage of CO2 into waste phosphogypsum: the modified Merseburg process. Clean Technol. Environ. Policy 18(8), 2709–2715 (2016). https://doi.org/10.1007/s10098-016-1157-4

Wang, X., Maroto-Valer, M., Shiwang, G., Shisen, X.: Aqueous ammonia capture integrated with ex-situ mineralisation using recyclable salts for industrial CCS. Energy Procedia 37, 7199–7204 (2013). https://doi.org/10.1016/j.egypro.2013.06.657

Dri, M., Sanna, A., Maroto-Valer, M.M.: Mineral carbonation from metal wastes: effect of solid to liquid ratio on the efficiency and characterization of carbonated products. Appl. Energy 113, 515–523 (2014). https://doi.org/10.1016/j.apenergy.2013.07.064

Abbas, K.K.: Study on the production of ammonium sulfate fertlizer from phosphogypsum. Eng. Technol. J. 29(4), 814–821 (2011). https://www.uotechnology.edu.iq/tec_magaz/volum292011/No.4.2011/text/Text%20(15).pdf

Vlasjan, S.V., Voloshin, N.D., Shestozub, A.B.: Producing calcium nitrate and rare-earth element concentrates by phosphogypsum conversion. Chem. Technol. 64(2), 58–62 (2014). https://doi.org/10.5755/j01.ct.64.2.6024

Mattila, H.P., Zevenhoven, R.: Mineral carbonation of phosphogypsum waste for production of useful carbonate and sulfate salts. Front. Energy Res. 3, 1–8 (2015). https://doi.org/10.3389/fenrg.2015.00048

Cai, Q., et al.: Efficient removal of phosphate impurities in waste phosphogypsum for the production of cement. Sci. Total Environ. 780, 146600 (2021). https://doi.org/10.1016/j.scitotenv.2021.146600

Rutherford, P.M., Dudas, M.J., Arocena, J.M.: Radioactivity and elemental composition of phosphogypsum produced from three phosphate rock sources. Waste Manage. Res. 13, 407–423 (1995). https://doi.org/10.1016/S0734-242X(05)80021-7

Grabas, K., Pawełczyk, A., Stręk, W., Szełęg, E., Stręk, S.: Study on the properties of waste apatite phosphogypsum as a raw material of prospective applications. Waste Biomass Valoriz (2018). https://doi.org/10.1007/s12649-018-0316-8

Bourgier, V.: Influence des ions monohydrogénophosphates et fluorophosphates sur les propriétés des phosphogypses et la réactivité des phosphoplâtres.,” Thèse de doctorat. Ecole Nationale Supérieure des Mines de Saint-Etienne (2008)

Hammas-Nasri, I., Elgharbi, S., Ferhi, M., Horchani-Naifera, K., Férid, M.: Investigation of phosphogypsum valorization by the integration of the Merseburg method. NJC 00, 1–8 (2020). https://doi.org/10.1039/D0NJ00387E

Acknowledgements

The authors wish to express their gratitude to Mrs Hinda SIRADJ and Mr. Brahim AKHSASSI for proofreading and polishing the language of our manuscript.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Idboufrade, A., Bouargane, B., Ennasraoui, B. et al. Phosphogypsum Two-Step Ammonia-Carbonation Resulting in Ammonium Sulfate and Calcium Carbonate Synthesis: Effect of the Molar Ratio OH−/Ca2+ on the Conversion Process. Waste Biomass Valor 13, 1795–1806 (2022). https://doi.org/10.1007/s12649-021-01600-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01600-0