Abstract

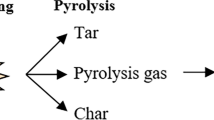

Biomass is an abundant source of energy, and its utilization will increase in the near future. One of the promising ways to recapture energy from biomass is by the gasification process. The primary product from biomass gasification (synthesis gas) can be used for a wide range of applications. By-products such as tar are also produced along with synthesis gas, which needs to be removed or converted catalytically. In recent times, a tremendous effort has been made to develop efficient and cheap catalysts for catalytic conversion of tar. Among many kinds of catalysts, the catalysts derived from natural minerals (olivine or dolomite) and solid waste (incinerated bottom ash or biochar) will make the process more sustainable. Therefore, in this review, the development of natural minerals and waste-derived catalysts for the biomass-derived tar reforming reaction was summarized. Besides tar conversion by thermal catalytic processes, the tar conversion is also highlighted using a low-temperature plasma process combined with catalysts. Furthermore, the possible process intensification by applying selective gas separable membranes was also summarized. The selective O2 permeable membrane at the tar reforming zone improves the stability of the catalyst and quality of syngas by gasifying the deposited coke during the reforming reaction. Finally, a conclusion section covering possible challenges associated with biomass tar reforming technology, membranes, and plasma catalysis was provided.

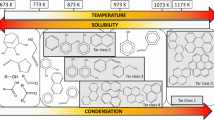

Graphic Abstract

Similar content being viewed by others

References

Magrini-Bair, K.A., Czernik, S., French, R., Parent, Y.O., Chornet, E., Dayton, D.C., Feik, C., Bain, R.: Fluidizable reforming catalyst development for conditioning biomass-derived syngas. Appl. Catal. A 318, 199–206 (2007)

Shen, Y., Wang, J., Ge, X., Chen, M.: By-products recycling for syngas cleanup in biomass pyrolysis—an overview. Renew. Sustain. Energy Rev. 59, 1246–1268 (2016)

Ashok, J., Kathiraser, Y., Ang, M.L., Kawi, S.: Bi-functional hydrotalcite-derived NiO-CaO-Al2O3 catalysts for steam reforming of biomass and/or tar model compound at low steam-to-carbon conditions. Appl. Catal. B-Environ. 172, 116–128 (2015)

González-Vázquez, M., García, R., Pevida, C., Rubiera, F.: Optimization of a bubbling fluidized bed plant for low-temperature gasification of biomass. Energies 10, 306 (2017)

Shen, Y., Fu, Y.: Advances in in situ and ex situ tar reforming with biochar catalysts for clean energy production. Sustain. Energy Fuels 2, 326–344 (2018)

Gómez-Barea, A., Leckner, B.: Gasification of biomass and waste. In: Lackner, M., Winter, F., Agarwal, A. K. (eds.) Handbook of Combustion, Vol. 4: Solid Fuels, pp. 365–397. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim (2010)

Yeo, T.Y., Ashok, J., Kawi, S.: Recent developments in sulphur-resilient catalytic systems for syngas production. Renew. Sustain. Energy Rev. 100, 52–70 (2019)

Kaiwen, L., Bin, Y., Tao, Z.: Economic analysis of hydrogen production from steam reforming process: a literature review. Energy Sources Part B 13, 109–115 (2017)

Kawi, S., Kathiraser, Y.: CO2 as an oxidant for high-temperature reactions. Front. Energy Res. 3, 13 (2015)

Shen, Y.: Chars as carbonaceous adsorbents/catalysts for tar elimination during biomass pyrolysis or gasification. Renew. Sustain. Energy Rev. 43, 281–295 (2015)

Ramzan, N., Ashraf, A., Naveed, S., Malik, A.: Simulation of hybrid biomass gasification using aspen plus: a comparative performance analysis for food, municipal solid and poultry waste. Biomass Bioenergy 35, 3962–3969 (2011)

Lopez, G., Artetxe, M., Amutio, M., Alvarez, J., Bilbao, J., Olazar, M.: Recent advances in the gasification of waste plastics. A critical overview. Renew. Sustain. Energy Rev. 82, 576–596 (2018)

Huang, S., Wu, S., Wu, Y., Gao, J.: Structure characteristics and gasification activity of residual carbon from updraft fixed-bed biomass gasification ash. Energy Convers. Manage. 136, 108–118 (2017)

Seo, Y.-C., Alam, M.T., Yang, W.-S.: Gasification of municipal solid waste. In: Yun, Y. (ed.) Gasification for Low-grade Feedstock. IntechOpen, London (2018)

Shen, Y., Yoshikawa, K.: Recent progresses in catalytic tar elimination during biomass gasification or pyrolysis—A review. Renew. Sustain. Energy Rev. 21, 371–392 (2013)

Asadullah, M.: Biomass gasification gas cleaning for downstream applications: a comparative critical review. Renew. Sustain. Energy Rev. 40, 118–132 (2014)

Shen, Y., Ma, D., Ge, X.: CO2-looping in biomass pyrolysis or gasification. Sustain. Energy Fuels 1, 1700–1729 (2017)

Mattisson, T., Keller, M., Linderholm, C., Moldenhauer, P., Rydén, M., Leion, H., Lyngfelt, A.: Chemical-looping technologies using circulating fluidized bed systems: status of development. Fuel Process. Technol. 172, 1–12 (2018)

Oreggioni, G.D., Singh, B., Cherubini, F., Guest, G., Lausselet, C., Luberti, M., Ahn, H., Strømman, A.H.: Environmental assessment of biomass gasification combined heat and power plants with absorptive and adsorptive carbon capture units in Norway. Int. J. Greenhouse Gas Control 57, 162–172 (2017)

Fuchs, J., Schmid, J.C., Müller, S., Hofbauer, H.: Dual fluidized bed gasification of biomass with selective carbon dioxide removal and limestone as bed material: a review. Renew. Sustain. Energy Rev. 107, 212–231 (2019)

Ashok, J., Dewangan, N., Das, S., Hongmanorom, P., Wai, M.H., Tomishige, K., Kawi, S.: Recent progress in the development of catalysts for steam reforming of biomass tar model reaction. Fuel Process. Technol. 199, 106252 (2020)

Shahbaz, M., Yusup, S., Inayat, A., Patrick, D.O., Ammar, M.: The influence of catalysts in biomass steam gasification and catalytic potential of coal bottom ash in biomass steam Gasification: A Review. Renew. Sustain. Energy Rev. 73, 468–476 (2017)

Cavattoni, T., Garbarino, G.: Catalytic abatement of biomass tar: a technological perspective of Ni-based catalysts. Rend. Lincei 28, 69–85 (2017)

Dou, B., Zhang, H., Song, Y., Zhao, L., Jiang, B., He, M., Ruan, C., Chen, H., Xu, Y.: Hydrogen production from the thermochemical conversion of biomass: issues and challenges. Sustain. Energy Fuels 3, 314–342 (2019)

Claude, V., Courson, C., Köhler, M., Lambert, S.D.: Overview and essentials of biomass gasification technologies and their catalytic cleaning methods. Energy Fuels 30, 8791–8814 (2016)

Sansaniwal, S.K., Pal, K., Rosen, M.A., Tyagi, S.K.: Recent advances in the development of biomass gasification technology: a comprehensive review. Renew. Sustain. Energy Rev. 72, 363–384 (2017)

Craven, M., Wang, Y., Yang, H., Wu, C., Tu, X.: Integrated gasification and non-thermal plasma-catalysis system for cleaner syngas production from cellulose. IOP Sci. Notes 1, 024001 (2020)

Bogaerts, A., Tu, X., Whitehead, J.C., Centi, G., Lefferts, L., Guaitella, O., Azzolina-Jury, F., Kim, H.-H., Murphy, A.B., Schneider, W.F., Nozaki, T., Hicks, J.C., Rousseau, A., Thevenet, F., Khacef, A., Carreon, M.: The 2020 plasma catalysis roadmap. J. Phys. D Appl. Phys. 53, 443001 (2020)

Anis, S., Zainal, Z.A.: Tar reduction in biomass producer gas via mechanical, catalytic and thermal methods: a review. Renew. Sustain. Energy Rev. 15, 2355–2377 (2011)

Sikarwar, V.S., Zhao, M., Clough, P., Yao, J., Zhong, X., Memon, M.Z., Shah, N., Anthony, E.J., Fennell, P.S.: An overview of advances in biomass gasification. Energy Environ. Sci. 9, 2939–2977 (2016)

Rakesh, N., Dasappa, S.: A critical assessment of tar generated during biomass gasification—formation, evaluation, issues and mitigation strategies. Renew. Sustain. Energy Rev. 91, 1045–1064 (2018)

Guan, G., Kaewpanha, M., Hao, X., Abudula, A.: Catalytic steam reforming of biomass tar: prospects and challenges. Renew. Sustain. Energy Rev. 58, 450–461 (2016)

Abdoulmoumine, N., Adhikari, S., Kulkarni, A., Chattanathan, S.: A review on biomass gasification syngas cleanup. Appl. Energy 155, 294–307 (2015)

Kathiraser, Y., Ashok, J., Kawi, S.: Synthesis and evaluation of highly dispersed SBA-15 supported Ni-Fe bimetallic catalysts for steam reforming of biomass derived tar reaction. Catal. Sci. Technol. 6, 4327–4336 (2016)

Ashok, J., Kawi, S.: Steam reforming of biomass tar model compound at relatively low steam-to-carbon condition over CaO-doped nickel-iron alloy supported over iron-alumina catalysts. Appl. Catal. A 490, 24–35 (2015)

Bian, Z.F., Kawi, S.: Preparation, characterization and catalytic application of phyllosilicate: a review. Catal. Today 339, 3–23 (2020)

Li, Z.W., Wang, Z.G., Kawi, S.: Sintering and coke resistant core/yolk shell catalyst for hydrocarbon reforming. ChemCatChem 11, 202–224 (2019)

Ashok, J., Kawi, S.: Nickel-iron alloy supported over iron-alumina catalysts for steam reforming of biomass tar model compound. ACS Catal. 4, 289–301 (2014)

He, L., Hu, S., Jiang, L., Liao, G., Chen, X., Han, H., Xiao, L., Ren, Q., Wang, Y., Su, S., Xiang, J.: Carbon nanotubes formation and its influence on steam reforming of toluene over Ni/Al2O3 catalysts: roles of catalyst supports. Fuel Process. Technol. 176, 7–14 (2018)

Adnan, M.A., Muraza, O., Razzak, S.A., Hossain, M.M., de Lasa, H.I.: Iron oxide over silica-doped alumina catalyst for catalytic steam reforming of toluene as a surrogate tar biomass species. Energy Fuels 31, 7471–7481 (2017)

Ashok, J., Kawi, S.: Steam reforming of toluene as a biomass tar model compound over CeO2 promoted Ni/CaO-Al2O3 catalytic systems. Int. J. Hydrog. Energy 38, 13938–13949 (2013)

Wu, C., Williams, P.T.: A novel nano-Ni/SiO2 catalyst for hydrogen production from steam reforming of ethanol. Environ. Sci. Technol. 44, 5993–5998 (2010)

Ashok, J., Bian, Z., Wang, Z., Kawi, S.: Ni-phyllosilicate structure derived Ni–SiO2–MgO catalysts for bi-reforming applications: acidity, basicity and thermal stability. Catal. Sci. Technol. 8, 1730–1742 (2018)

Kathiraser, Y., Wang, Z., Ang, M.L., Mo, L., Li, Z., Oemar, U., Kawi, S.: Highly active and coke resistant Ni/SiO2 catalysts for oxidative reforming of model biogas: Effect of low ceria loading. J. CO2 Util. 19, 284–295 (2017)

Blanco, P.H., Wu, C., Onwudili, J.A., Williams, P.T.: Characterization and evaluation of Ni/SiO2 catalysts for hydrogen production and tar reduction from catalytic steam pyrolysis-reforming of refuse derived fuel. Appl. Catal. B 134–135, 238–250 (2013)

Ashok, J., Kathiraser, Y., Ang, M.L., Kawi, S.: Ni and/or Ni-Cu alloys supported over SiO2 catalysts synthesized via phyllosilicate structures for steam reforming of biomass tar reaction. Catal. Sci. Technol. 5, 4398–4409 (2015)

Li, Z., Li, M., Ashok, J., Kawi, S.: NiCo@NiCo phyllosilicate@CeO2 hollow core shell catalysts for steam reforming of toluene as biomass tar model compound. Energy Convers. Manage. 180, 822–830 (2019)

Ahmed, T., Xiu, S., Wang, L., Shahbazi, A.: Investigation of Ni/Fe/Mg zeolite-supported catalysts in steam reforming of tar using simulated-toluene as model compound. Fuel 211, 566–571 (2018)

Oemar, U., Li, A.M., Hidajat, K., Kawi, S.: Mechanism and kinetic modeling for steam reforming of toluene on La0.8Sr0.2Ni0.8Fe0.2O3 catalyst. AlChE J. 60, 4190–4198 (2014)

Laosiripojana, N., Sutthisripok, W., Charojrochkul, S., Assabumrungrat, S.: Development of Ni–Fe bimetallic based catalysts for biomass tar cracking/reforming: effects of catalyst support and co-fed reactants on tar conversion characteristics. Fuel Process. Technol. 127, 26–32 (2014)

Ashok, J., Das, S., Dewangan, N., Kawi, S.: H2S and NOx tolerance capability of CeO2 doped La1−xCexCo0.5Ti0.5O3−δ perovskites for steam reforming of biomass tar model reaction. Energy Convers. Manage.: X 1, 100003 (2019)

Oemar, U., Ang, M.L., Hee, W.F., Hidajat, K., Kawi, S.: Perovskite LaxM1−xNi0.8Fe0.2O3 catalyst for steam reforming of toluene: crucial role of alkaline earth metal at low steam condition. Appl. Catal. B: Environ. 148–149, 231–242 (2014)

Takise, K., Higo, T., Mukai, D., Ogo, S., Sugiura, Y., Sekine, Y.: Highly active and stable Co/La0.7Sr0.3AlO3−δ catalyst for steam reforming of toluene. Catal. Today 265, 111–117 (2016)

Nichele, V., Signoretto, M., Pinna, F., Menegazzo, F., Rossetti, I., Cruciani, G., Cerrato, G., Di Michele, A.: Ni/ZrO2 catalysts in ethanol steam reforming: Inhibition of coke formation by CaO-doping. Appl. Catal. B 150–151, 12–20 (2014)

Abou Rached, J., El Hayek, C., Dahdah, E., Gennequin, C., Aouad, S., Tidahy, H.L., Estephane, J., Nsouli, B., Aboukaïs, A., Abi-Aad, E.: Ni based catalysts promoted with cerium used in the steam reforming of toluene for hydrogen production. Int. J. Hydrog. Energy 42, 12829–12840 (2017)

Corella, J., Aznar, M.P., Delgado, J., Aldea, E.: Steam gasification of cellulosic wastes in a fluidized bed with downstream vessels. Ind. Eng. Chem. Res. 30, 2252–2262 (1991)

Delgado, J., Aznar, M.P., Corella, J.: Biomass gasification with steam in fluidized bed: effectiveness of CaO, MgO, and CaO−MgO for hot raw gas cleaning. Ind. Eng. Chem. Res. 36, 1535–1543 (1997)

Pérez, P., Aznar, P.M., Caballero, M.A., Gil, J., Martín, J.A., Corella, J.: Hot gas cleaning and upgrading with a calcined dolomite located downstream a biomass fluidized bed gasifier operating with steam−oxygen mixtures. Energy Fuels 11, 1194–1203 (1997)

Aznar, M.P., Corella, J., Delgado, J., Lahoz, J.: Improved steam gasification of lignocellulosic residues in a fluidized bed with commercial steam reforming catalysts. Ind. Eng. Chem. Res. 32, 1–10 (1993)

Constantinou, D.A., Fierro, J.L.G., Efstathiou, A.M.: The phenol steam reforming reaction towards H2 production on natural calcite. Appl. Catal. B 90, 347–359 (2009)

Constantinou, D.A., Fierro, J.L.G., Efstathiou, A.M.: A comparative study of the steam reforming of phenol towards H2 production over natural calcite, dolomite and olivine materials. Appl. Catal. B 95, 255–269 (2010)

Kuhn, J.N., Zhao, Z., Felix, L.G., Slimane, R.B., Choi, C.W., Ozkan, U.S.: Olivine catalysts for methane- and tar-steam reforming. Appl. Catal. B 81, 14–26 (2008)

Michel, R., Łamacz, A., Krzton, A., Djéga-Mariadassou, G., Burg, P., Courson, C., Gruber, R.: Steam reforming of α-methylnaphthalene as a model tar compound over olivine and olivine supported nickel. Fuel 109, 653–660 (2013)

Yang, X., Xu, S., Xu, H., Liu, X., Liu, C.: Nickel supported on modified olivine catalysts for steam reforming of biomass gasification tar. Catal. Commun. 11, 383–386 (2010)

Min, Z., Asadullah, M., Yimsiri, P., Zhang, S., Wu, H., Li, C.-Z.: Catalytic reforming of tar during gasification. Part I. Steam reforming of biomass tar using ilmenite as a catalyst. Fuel 90, 1847–1854 (2011)

Virginie, M., Courson, C., Niznansky, D., Chaoui, N., Kiennemann, A.: Characterization and reactivity in toluene reforming of a Fe/olivine catalyst designed for gas cleanup in biomass gasification. Appl. Catal. B 101, 90–100 (2010)

Liu, H., Chen, T., Chang, D., Chen, D., Kong, D., Zou, X., Frost, R.L.: Effect of preparation method of palygorskite-supported Fe and Ni catalysts on catalytic cracking of biomass tar. Chem. Eng. J. 188, 108–112 (2012)

Guan, G., Chen, G., Kasai, Y., Lim, E.W.C., Hao, X., Kaewpanha, M., Abuliti, A., Fushimi, C., Tsutsumi, A.: Catalytic steam reforming of biomass tar over iron- or nickel-based catalyst supported on calcined scallop shell. Appl. Catal. B 115–116, 159–168 (2012)

Guan, G., Kaewpanha, M., Hao, X., Zhu, A.-M., Kasai, Y., Kakuta, S., Kusakabe, K., Abudula, A.: Steam reforming of tar derived from lignin over pompom-like potassium-promoted iron-based catalysts formed on calcined scallop shell. Bioresour. Technol. 139, 280–284 (2013)

Guan, G., Kaewpanha, M., Hao, X., Wang, Z., Cheng, Y., Kasai, Y., Abudula, A.: Promoting effect of potassium addition to calcined scallop shell supported catalysts for the decomposition of tar derived from different biomass resources. Fuel 109, 241–247 (2013)

Kaewpanha, M., Karnjanakom, S., Guan, G., Hao, X., Yang, J., Abudula, A.: Removal of biomass tar by steam reforming over calcined scallop shell supported Cu catalysts. J. Energy Chem. 26, 660–666 (2017)

Valizadeh, S., Lam, S.S., Ko, C.H., Lee, S.H., Farooq, A., Yu, Y.J., Jeon, J.-K., Jung, S.-C., Rhee, G.H., Park, Y.-K.: Biohydrogen production from catalytic conversion of food waste via steam and air gasification using eggshell- and homo-type Ni/Al2O3 catalysts. Bioresour. Technol. 320, 124313 (2021)

Yang, J., Kaewpanha, M., Karnjanakom, S., Guan, G., Hao, X., Abudula, A.: Steam reforming of biomass tar over calcined egg shell supported catalysts for hydrogen production. Int. J. Hydrog. Energy 41, 6699–6705 (2016)

Al-Rahbi, A.S., Williams, P.T.: Waste ashes as catalysts for the pyrolysis–catalytic steam reforming of biomass for hydrogen-rich gas production. J. Mater. Cycles Waste Manage. 21, 1224–1231 (2019)

Dou, X., Ren, F., Nguyen, M.Q., Ahamed, A., Yin, K., Chan, W.P., Chang, V.W.-C.: Review of MSWI bottom ash utilization from perspectives of collective characterization, treatment and existing application. Renew. Sustain. Energy Rev. 79, 24–38 (2017)

Brück, F., Fröhlich, C., Mansfeldt, T., Weigand, H.: A fast and simple method to monitor carbonation of MSWI bottom ash under static and dynamic conditions. Waste Manage. 78, 588–594 (2018)

Lancellotti, I., Ponzoni, C., Barbieri, L., Leonelli, C.: Alkali activation processes for incinerator residues management. Waste Manage. 33, 1740–1749 (2013)

Rendek, E., Ducom, G., Germain, P.: Carbon dioxide sequestration in municipal solid waste incinerator (MSWI) bottom ash. J. Hazard. Mater. 128, 73–79 (2006)

Ashok, J., Das, S., Yeo, T.Y., Dewangan, N., Kawi, S.: Incinerator bottom ash derived from municipal solid waste as a potential catalytic support for biomass tar reforming. Waste Manage. 82, 249–257 (2018)

Guo, F., Jia, X., Liang, S., Zhou, N., Chen, P., Ruan, R.: Development of biochar-based nanocatalysts for tar cracking/reforming during biomass pyrolysis and gasification. Bioresour. Technol. 298, 122263 (2019)

Uzi, A., Shen, Y., Kawi, S., Levy, A., Wang, C.-H.: Permittivity and chemical characterization of woody biomass during pyrolysis and gasification. Chem. Eng. J. 355, 255–268 (2019)

Nestler, F., Burhenne, L., Amtenbrink, M.J., Aicher, T.: Catalytic decomposition of biomass tars: the impact of wood char surface characteristics on the catalytic performance for naphthalene removal. Fuel Process. Technol. 145, 31–41 (2016)

Mun, T.-Y., Seon, P.-G., Kim, J.-S.: Production of a producer gas from woody waste via air gasification using activated carbon and a two-stage gasifier and characterization of tar. Fuel 89, 3226–3234 (2010)

Wang, D., Yuan, W., Ji, W.: Char and char-supported nickel catalysts for secondary syngas cleanup and conditioning. Appl. Energy 88, 1656–1663 (2011)

Guo, F., Li, X., Liu, Y., Peng, K., Guo, C., Rao, Z.: Catalytic cracking of biomass pyrolysis tar over char-supported catalysts. Energy Convers. Manage. 167, 81–90 (2018)

Abu El-Rub, Z., Bramer, E.A., Brem, G.: Experimental comparison of biomass chars with other catalysts for tar reduction. Fuel 87, 2243–2252 (2008)

Buentello-Montoya, D., Zhang, X.: An energy and exergy analysis of biomass gasification integrated with a char-catalytic tar reforming system. Energy Fuels 33, 8746–8757 (2019)

Liu, J., He, Y., Ma, X., Liu, G., Yao, Y., Liu, H., Chen, H., Huang, Y., Chen, C., Wang, W.: Catalytic pyrolysis of tar model compound with various bio-char catalysts to recycle char from biomass pyrolysis. BioResources 11, 3752–3768 (2016)

Kirtania, K., Joshua, J., Kassim, M.A., Bhattacharya, S.: Comparison of CO2 and steam gasification reactivity of algal and woody biomass chars. Fuel Process. Technol. 117, 44–52 (2014)

Richardson, Y., Motuzas, J., Julbe, A., Volle, G., Blin, J.: Catalytic investigation of in situ generated Ni metal nanoparticles for tar conversion during biomass pyrolysis. J. Phys. Chem. C 117, 23812–23831 (2013)

Yu, J., Tian, F.J., McKenzie, L.J., Li, C.Z.: Char-supported nano iron catalyst for water-gas-shift reaction: hydrogen production from coal/biomass gasification. Process Saf. Environ. Prot. 84, 125–130 (2006)

Shen, Y., Zhao, P., Shao, Q., Takahashi, F., Yoshikawa, K.: In situ catalytic conversion of tar using rice husk char/ash supported nickel–iron catalysts for biomass pyrolytic gasification combined with the mixing-simulation in fluidized-bed gasifier. Appl. Energy 160, 808–819 (2015)

Guo, F., Peng, K., Liang, S., Jia, X., Jiang, X., Qian, L.: One-step synthesis of biomass activated char supported copper nanoparticles for catalytic cracking of biomass primary tar. Energy 180, 584–593 (2019)

Corella, J., Toledo, J.M., Aznar, M.-P.: Improving the modeling of the kinetics of the catalytic tar elimination in biomass gasification. Ind. Eng. Chem. Res. 41, 3351–3356 (2002)

Friend, C.M., Muetterties, E.L.: Coordination chemistry of metal surfaces. 3. Benzene and toluene interactions with nickel surfaces. J. Am. Chem. Soc. 103, 773–779 (1981)

Mei, D., Lebarbier, V.M., Rousseau, R., Glezakou, V.-A., Albrecht, K.O., Kovarik, L., Flake, M., Dagle, R.A.: Comparative investigation of benzene steam reforming over spinel supported Rh and Ir catalysts. ACS Catal. 3, 1133–1143 (2013)

Carey, S.J., Zhao, W., Mao, Z., Campbell, C.T.: Energetics of adsorbed phenol on Ni(111) and Pt(111) by calorimetry. J. Phys. Chem. C 123, 7627–7632 (2019)

Du, Z.-Y., Zhang, Z.-H., Xu, C., Wang, X.-B., Li, W.-Y.: Low-temperature steam reforming of toluene and biomass tar over biochar-supported Ni nanoparticles. ACS Sustain. Chem. Eng. 7, 3111–3119 (2019)

Świerczyński, D., Libs, S., Courson, C., Kiennemann, A.: Steam reforming of tar from a biomass gasification process over Ni/olivine catalyst using toluene as a model compound. Appl. Catal. B 74, 211–222 (2007)

Simell, P.A., Hakala, N.A.K., Haario, H.E., Krause, A.O.I.: Catalytic decomposition of gasification gas tar with benzene as the model compound. Ind. Eng. Chem. Res. 36, 42–51 (1997)

Simell, P.A., Hirvensalo, E.K., Smolander, V.T., Krause, A.O.I.: Steam reforming of gasification gas tar over dolomite with benzene as a model compound. Ind. Eng. Chem. Res. 38, 1250–1257 (1999)

Kaisalo, N., Simell, P., Lehtonen, J.: Benzene steam reforming kinetics in biomass gasification gas cleaning. Fuel 182, 696–703 (2016)

Mazumder, J., de Lasa, H.I.: Steam gasification of a cellulosic biomass surrogate using a Ni/La2O3-γAl2O3 catalyst in a CREC fluidized riser simulator. Kinetics and model validation. Fuel 216, 101–109 (2018)

Oemar, U., Ming Li, A., Hidajat, K., Kawi, S.: Mechanism and kinetic modeling for steam reforming of toluene on La0.8Sr0.2Ni0.8Fe0.2O3 catalyst. AIChE J. 60, 4190–4198 (2014)

Mukai, D., Tochiya, S., Murai, Y., Imori, M., Sugiura, Y., Sekine, Y.: Structure and activity of Ni/La0.7Sr0.3AlO3−δ catalyst for hydrogen production by steam reforming of toluene. Appl. Catal. A: Gen. 464–465, 78–86 (2013)

Zhao, X., Xue, Y., Lu, Z., Huang, Y., Guo, C., Yan, C.: Encapsulating Ni/CeO2-ZrO2 with SiO2 layer to improve it catalytic activity for steam reforming of toluene. Catal. Commun. 101, 138–141 (2017)

Takise, K., Imori, M., Mukai, D., Ogo, S., Sugiura, Y., Sekine, Y.: Effect of catalyst structure on steam reforming of toluene over Ni/La0.7Sr0.3AlO3−δ catalyst. Appl. Catal. A: Gen. 489, 155–161 (2015)

Xu, D., Xiong, Y., Zhang, S., Su, Y.: The influence of preparation method of char supported metallic Ni catalysts on the catalytic performance for reforming of biomass tar. Int. J. Energy Res. 43, 6922–6933 (2019)

Devi, L., Ptasinski, K.J., Janssen, F.J.J.G.: A review of the primary measures for tar elimination in biomass gasification processes. Biomass Bioenergy 24, 125–140 (2003)

Wang, Z., Oemar, U., Ang, M.L., Kawi, S.: Oxidative steam reforming of biomass tar model compound via catalytic BaBi0.05Co0.8Nb0.15O3−δ hollow fiber membrane reactor. J. Membr. Sci. 510, 417–425 (2016)

Wang, Z., Ashok, J., Pu, Z., Kawi, S.: Low temperature partial oxidation of methane via BaBi0.05Co0.8Nb0.15O3−δ-Ni phyllosilicate catalytic hollow fiber membrane reactor. Chem. Eng. J. 315, 315–323 (2017)

Wang, Z., Bian, Z., Dewangan, N., Xu, J., Kawi, S.: High-performance catalytic perovskite hollow fiber membrane reactor for oxidative propane dehydrogenation. J. Membr. Sci. 578, 36–42 (2019)

Wang, Z., Dewangan, N., Das, S., Wai, M.H., Kawi, S.: High oxygen permeable and CO2-tolerant SrCoxFe0.9-xNb0.1O3-Δ (x = 0.1–0.8) perovskite membranes: behavior and mechanism. Sep Purif Technol 201, 30–40 (2018)

Wang, Z., Kathiraser, Y., Soh, T., Kawi, S.: Ultra-high oxygen permeable BaBiCoNb hollow fiber membranes and their stability under pure CH4 atmosphere. J. Membr. Sci. 465, 151–158 (2014)

Jangam, A., Das, S., Dewangan, N., Hongmanorom, P., Hui, W.M., Kawi, S.: Conversion of CO2 to C1 chemicals: catalyst design, kinetics and mechanism aspects of the reactions. Catal. Today 358, 3–29 (2019)

Wang, Z., Kathiraser, Y., Ang, M.L., Kawi, S.: High purity oxygen production via BBCN perovskite hollow fiber membrane swept by steam. Ind. Eng. Chem. Res. 54, 6371–6377 (2015)

Wang, Z., Kathiraser, Y., Kawi, S.: High performance oxygen permeable membranes with Nb-doped BaBi0.05Co0.95O3−δ perovskite oxides. J. Membr. Sci. 431, 180–186 (2013)

Kathiraser, Y., Wang, Z., Yang, N.-T., Zahid, S., Kawi, S.: Oxygen permeation and stability study of La0.6Sr0.4Co0.8Ga0.2O3−δ (LSCG) hollow fiber membrane with exposure to CO2, CH4 and He. J. Membr. Sci. 427, 240–249 (2013)

Han, N., Wei, Q., Zhang, S., Yang, N., Liu, S.: Rational design via tailoring Mo content in La2Ni1-xMoxO4+δ to improve oxygen permeation properties in CO2 atmosphere. J. Alloys Compd. 806, 153–162 (2019)

Gu, X., Jin, W., Chen, C., Xu, N., Shi, J., Ma, Y.H.: YSZ-SRCo0.4Fe0.6O3-δ membranes for the partial oxidation of methane to syngas. AIChE J. 48, 2051–2060 (2002)

Kathiraser, Y., Wang, Z., Kawi, S.: Oxidative CO2 reforming of methane in La0.6Sr0.4Co0.8Ga0.2O3-δ (LSCG) hollow fiber membrane reactor. Environ. Sci. Technol. 47, 14510–14517 (2013)

Jin, Y., Rui, Z., Tian, Y., Lin, Y., Li, Y.: Sequential simulation of dense oxygen permeation membrane reactor for hydrogen production from oxidative steam reforming of ethanol with ASPEN PLUS. Int. J. Hydrog. Energy 35, 6691–6698 (2010)

Jin, Y., Rui, Z., Tian, Y., Lin, Y.S., Li, Y.: Autothermal reforming of ethanol in dense oxygen permeation membrane reactor. Catal. Today 264, 214–220 (2016)

Liu, S., Mei, D., Wang, L., Tu, X.: Steam reforming of toluene as biomass tar model compound in a gliding arc discharge reactor. Chem. Eng. J. 307, 793–802 (2017)

Zhang, H., Zhu, F., Li, X., Xu, R., Li, L., Yan, J., Tu, X.: Steam reforming of toluene and naphthalene as tar surrogate in a gliding arc discharge reactor. J. Hazard. Mater. 369, 244–253 (2019)

Liu, L., Zhang, Z., Das, S., Kawi, S.: Reforming of tar from biomass gasification in a hybrid catalysis-plasma system: a review. Appl. Catal. B 250, 250–272 (2019)

Jamróz, P., Kordylewski, W., Wnukowski, M.: Microwave plasma application in decomposition and steam reforming of model tar compounds. Fuel Process. Technol. 169, 1–14 (2018)

Bogaerts, A., Neyts, E.C.: Plasma technology: an emerging technology for energy storage. ACS Energy Lett. 3, 1013–1027 (2018)

Młotek, M., Ulejczyk, B., Woroszył, J., Walerczak, I., Krawczyk, K.: Purification of the gas after pyrolysis in coupled plasma-catalytic system. Pol. J. Chem. Technol. 19, 94–98 (2017)

Liu, S., Mei, D., Shen, Z., Tu, X.: Nonoxidative conversion of methane in a dielectric barrier discharge reactor: prediction of reaction performance based on neural network model. J. Phys. Chem. C 118, 10686–10693 (2014)

Liu, L., Wang, Q., Ahmad, S., Yang, X., Ji, M., Sun, Y.: Steam reforming of toluene as model biomass tar to H2-rich syngas in a DBD plasma-catalytic system. J. Energy Inst. 91, 927–939 (2018)

Dors, M., Kurzyńska, D.: Tar removal by nanosecond pulsed dielectric barrier discharge. Appl. Sci. 10, 991 (2020)

Rahimpour, M.R., Jahanmiri, A., Rostami, P., Taghvaei, H., Gates, B.C.: Upgrading of anisole in a catalytic pulsed dielectric barrier discharge plasma reactor. Energy Fuels 27, 7424–7431 (2013)

Liu, L., Wang, Q., Song, J., Ahmad, S., Yang, X., Sun, Y.: Plasma-assisted catalytic reforming of toluene to hydrogen rich syngas. Catal. Sci. Technol. 7, 4216–4231 (2017)

Liu, S., Mei, D., Nahil, M., Gadkari, S., Gu, S., Williams, P., Tu, X.: Hybrid plasma-catalytic steam reforming of toluene as a biomass tar model compound over Ni/Al2O3 catalysts. Fuel Process. Technol. 166, 269–275 (2017)

Tao, K., Ohta, N., Liu, G., Yoneyama, Y., Wang, T., Tsubaki, N.: Plasma enhanced catalytic reforming of biomass tar model compound to syngas. Fuel 104, 53–57 (2013)

Blanquet, E., Nahil, M.A., Williams, P.T.: Enhanced hydrogen-rich gas production from waste biomass using pyrolysis with non-thermal plasma-catalysis. Catal. Today 337, 216–224 (2019)

Zhu Chen, J., Wu, Z., Zhang, X., Choi, S., Xiao, Y., Varma, A., Liu, W., Zhang, G., Miller, J.T.: Identification of the structure of the Bi promoted Pt non-oxidative coupling of methane catalyst: a nanoscale Pt3Bi intermetallic alloy. Catal. Sci. Technol. 9, 1349–1356 (2019)

Mei, D., Liu, S., Wang, Y., Yang, H., Bo, Z., Tu, X.: Enhanced reforming of mixed biomass tar model compounds using a hybrid gliding arc plasma catalytic process. Catal. Today 337, 225–233 (2019)

Cimerman, R., Račková, D., Hensel, K.: Tars removal by non-thermal plasma and plasma catalysis. J. Phys. D Appl. Phys. 51, 274003 (2018)

Liu, Y., Song, J., Diao, X., Liu, L., Sun, Y.: Removal of tar derived from biomass gasification via synergy of non-thermal plasma and catalysis. Sci. Total Environ. 721, 137671 (2020)

Wang, Y., Yang, H., Tu, X.: Plasma reforming of naphthalene as a tar model compound of biomass gasification. Energy Convers. Manage. 187, 593–604 (2019)

Mei, D., Wang, Y., Liu, S., Alliati, M., Yang, H., Tu, X.: Plasma reforming of biomass gasification tars using mixed naphthalene and toluene as model compounds. Energy Convers. Manage. 195, 409–419 (2019)

Młotek, M., Ulejczyk, B., Woroszył, J., Krawczyk, K.: Decomposition of toluene in coupled plasma-catalytic system. Ind. Eng. Chem. Res. 59, 4239–4244 (2020)

Zheng, C., Zhu, X., Gao, X., Liu, L., Chang, Q., Luo, Z., Cen, K.: Experimental study of acetone removal by packed-bed dielectric barrier discharge reactor. J. Ind. Eng. Chem. 20, 2761–2768 (2014)

Xu, B., Xie, J., Yin, X., Liu, H., Sun, C., Wu, C.: Mechanisms of toluene removal in relation to the main components of biosyngas in a catalytic nonthermal plasma process. Energy Fuels 33, 4287–4301 (2019)

Wang, Z., Chen, T., Dewangan, N., Li, Z., Das, S., Pati, S., Li, Z., Lin, J.Y.S., Kawi, S.: Catalytic mixed conducting ceramic membrane reactors for methane conversion. React. Chem. Eng. 5, 1868–1891 (2020)

Acknowledgements

The authors gratefully thank the financial support from National University of Singapore, National Research Foundation, Prime Minister's Office, Singapore, the National Environment Agency under the Waste-to-Energy Competitive Research Program (WTE CRP 1501 103, WBS No. R-279-000-491-279), Agency for Science, Technology, and Research (AME-IRG A1783c0016, WBS No. R-279-000-509-305) and Ministry of Education (MOE2017-T2-2-130, WBS No. R-279-000-544-112)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kawi, S., Ashok, J., Dewangan, N. et al. Recent Advances in Catalyst Technology for Biomass Tar Model Reforming: Thermal, Plasma and Membrane Reactors. Waste Biomass Valor 13, 1–30 (2022). https://doi.org/10.1007/s12649-021-01446-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01446-6