Abstract

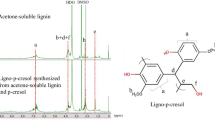

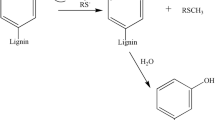

Low-molecular weight lignin was used as a curing agent to synthesize a bio-based cured epoxy resin. The low-molecular weight lignin was extracted from moso bamboo using steam treatment at 10–40 atm for 5 min followed by milling treatment for 10 s and then water and acetone extractions. The number and weight average molecular weight of low-molecular weight lignin, i.e. acetone soluble component, were 554–698 and 1460–3240, respectively. Furthermore, the hydroxyl equivalent of low-molecular weight lignin were 111–169 g-lignin/eq. The lignin-cured epoxy resin was made from EP828 (a commercial diglycidyl ether bisphenol A epoxy resin) with the low-molecular weight lignin as a curing agent. The decomposition temperature at 5% weight loss (Td5) of lignin-cured epoxy resins were 298–327 °C and the maximum value, i.e. 327 °C, was obtained using a low-molecular weight lignin at 30 atm. Though Td5 varied with the steam pressure, all values satisfied the thermal stability property required for soldering resistance in the electronic substrate field, i.e. beyond 250 °C. The tensile strengths of lignin-cured epoxy resins were 44–59 MPa and these values satisfied the tensile strength of commercial cured epoxy resins, i.e. beyond 27 MPa.

Graphic Abstract

Similar content being viewed by others

References

Kamm, B., Kamm, M.: Principles of biorefineries. Appl. Microbiol. Biotechnol. 64, 137–145 (2004)

Ellis, B.: Introduction to the chemistry, synthesis, manufacture and characterization of epoxy resins. In: Ellis, B. (ed.) Chemistry and Technology of Epoxy Resins, pp. 1–36. Springer, Michigan (1993)

Markaverich, B., Webb, B., Densmore, C., Gregory, R.: Effects of coumestrol on estrogen receptor function and uterine growth in ovariectomized rats. Environ. Health. Perspect. 103, 574–581 (1995)

Raquez, J., Deleglise, M., Lacrampe, M., Krawczak, P.: Thermosetting (bio)materials derived from renewable resources: a critical review. Prog. Polym. Sci. 35, 487–509 (2010)

Crivello, J.V., Narayan, R., Sternstein, S.S.: Fabrication and mechanical characterization of glass fiber reinforced UV-cured composites from epoxidized vegetable oils. J. Appl. Polym. Sci. 64, 2073–2087 (1997)

Vlcek, T., Petrovic, Z.S.: Optimization of the chemoenzymatic epoxidation of soybean oil. J. Amer. Oil Chem. Soc. 83, 247–252 (2006)

Zeleke, T.D., Ayana, Y.M.: Epoxidation of vernonia oil in acidic ion exchange resin. Am. J. Appl. Chem. 5, 1–6 (2017)

Goud, V.V., Patwardhan, A.V., Dinda, S., Pradhan, N.C.: Epoxidation of karanja (Pongamia glabra) oil catalysed by acidic ion exchange resin. Eur. J. Lipid Sci. Technol. 109, 575–584 (2007)

Ma, S., Liu, X., Jiang, Y., Tang, Z., Zhang, C., Zhu, J.: Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem. 15, 245–254 (2013)

Benyahya, S., Aouf, C., Caillol, S., Boutevin, B., Pascault, J.P., Fulcrand, H.: Functionalized green tea tannins as phenolic prepolymers for bio-based epoxy resins. Ind. Crop. Prod. 53, 296–307 (2014)

Sasaki, C., Wanaka, M., Takagi, H., Tamura, S., Asada, C., Nakamura, Y.: Evaluation of epoxy resins synthesized from steam-exploded bamboo lignin. Ind. Crops Prod. 43, 757–761 (2013)

Kishi, H., Akamatsu, Y., Noguchi, M., Fujita, A., Matsuda, S., Nishida, H.: Synthesis of epoxy resins from alcohol-liquefied wood and the mechanical properties of the cured resins. J. Appl. Polym. Sci. 120, 745–761 (2011)

Asada, C., Sasaki, C., Suzuki, A., Nakamura, Y.: Total biorefinery process of lignocellulosic waste using steam explosion followed by water and acetone extractions. Waste Biomass Valori. 9, 2423–2432 (2018)

Jablonskis, A., Arshanitsa, A., Arnautov, A., Telysheva, G., Evtuguin, D.: Evaluation of Ligno BoostTM softwood kraft lignin epoxidation as an approach for its application in cured epoxy resins. Ind. Crops Prod. 112, 225–235 (2018)

Nagatani, M., Tsurumaki, A., Takamatsu, K., Saito, H., Nakamura, N., Ohno, H.: Preparation of epoxy resins derived from lignin solubilized in tetrabutylphosphonium hydroxide aqueous solutions. Int. J. Biol. Macromol. 132, 585–591 (2019)

Nisha, S.S., Nikzad, M., Kobaisi, M.A., Truong, V.K., Sbarski, I.: The role of ionic-liquid extracted lignin micro/nanoparticles for functionalisation of an epoxy-based composite matrix. Compos. Sci. Technol. 174, 11–19 (2019)

Ortiz, P., Wiekamp, M., Vendamme, R., Eevers, W.: Bio-based epoxy resins from biorefinery by-products. BioResources 14, 3200–3209 (2019)

Ferdosian, F., Yuan, Z., Anderson, M., Xu, C.C.: Thermal performance and thermal decomposition kinetics of lignin-based epoxy resins. J. Anal. Appl. Pyrolysis 119, 124–132 (2016)

Asada, C., Kita, A., Sasaki, C., Nakamura, Y.: Ethanol production from disposable aspen chopsticks using delignification. Carbohydr. Polym. 85, 196–200 (2011)

Bauer, A., Lizasoain, J., Theuretzbacher, F., Agger, J.W., Rincon, M., Menardo, S., Saylor, M.K., Enguidanos, R., Nielsen, P.J., Potthast, A., Zweckmair, T., Gronauer, A., Horn, S.J.: Steam explosion pretreatment for enhancing biogas production of late harvested hay. Bioresour. Technol. 166, 403–410 (2014)

Garmakhany, A.D., Kashaninejad, M., Aalami, M., Maghsoudlou, Y., Khomieri, M., Tabil, L.G.: Enhanced biomass delignification and enzymatic saccharification of canola straw by steam-explosion pretreatment. J. Sci. Food Agric. 94, 1607–1613 (2013)

Shevchenko, S.M., Chang, K., Robinson, J., Saddler, J.N.: Optimization of monosaccharide recovery by post-hydrolysis of the water-soluble hemicelluloses component after steam explosion of softwood chips. Bioresour. Technol. 72, 207–211 (2000)

Alvira, P., Tomas-Pejo, E., Ballesteros, M., Negro, M.J.: Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 101, 4851–4861 (2010)

Chen, H., Qiu, W.: Key technologies for bioethanol production from lignocellulose. Biotechnol. Adv. 28, 556–562 (2010)

Liu, C.G., Liu, L.Y., Zi, L.H., Zhao, X.Q., Xu, Y.H., Bai, F.W.: Assessment and regression analysis on instant catapult steam explosion pretreatment of corn stover. Bioresour. Technol. 166, 368–372 (2014)

Yu, Z., Zhang, B., Yu, F., Xu, G., Song, A.: A real explosion: The requirement of steam explosion pretreatment. Bioresour. Technol. 121, 335–341 (2012)

He, M.X., Wang, J.L., Qin, H., Shui, Z.X., Zhu, Z.X., Wu, B., Tan, F.R., Pan, K., Hu, Q.C., Dai, L.C., Wang, W.G., Tang, X.Y., Hu, G.Q.: Bamboo: A new source of carbohydrate for biorefinery. Carbohydr. Polym. 111, 645–654 (2014)

Suzuki, A., Sasaki, C., Asada, C., Nakamura, Y.: Production of cellulose nanofibers from Aspen and Bode chopsticks using a high temperature and high pressure steam treatment with milling. Carbohydr. Polym. 194, 303–310 (2018)

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., Crocker, D.: Determination of structural carbohydrates and lignin in biomass, Laboratory Analytical Procedure (LAP): Technical Report NREL/TP-510-42618. National Renewable Energy Laboratory, Golden (2011)

Asada, C., Basnet, S., Otsuka, T., Sasaki, C., Nakamura, Y.: Epoxy resin synthesis using low molecular weight lignin separated from various lignocellulosic materials. Int. J. Biol. Macromol. 74, 413–419 (2015)

Palmqvist, E., Hahn-Hagerdal, B.: Fermentation of lignocellulosic hydrolysates II: Inhibitors and mechanisms of inhibition. Bioresour. Technol. 74, 25–33 (2000)

Wang, P., Fu, Y., Shao, Z., Zhang, F., Qin, M.: Structural changes to aspen wood lignin during autohydrolysis pretreatment. BioResources 11, 4086–4103 (2016)

Maniet, G., Schmetz, Q., Jacquet, N., Temmerman, M., Gofflot, S., Richel, A.: Effect of steam explosion treatment on chemical composition and characteristic of organosolv fescue lignin. Ind. Crops Prod. 99, 79–85 (2017)

Chua, M.G.S., Wayman, M.: Characterization of autohydrolysis aspen (P tremuloides) lignins part 1: Composition and molecular weight distribution of extracted autohydrolysis lignin. Can. J. Chem. 57, 1141–1149 (1979)

Asada, C., Nakamura, Y., Kobayashi, F.: Chemical characteristics and ethanol fermentation of the cellulose component in autohydrolyzed bagasse. Biotechnol. Biopro. Eng. 10, 346–352 (2005)

Basnet, S., Otsuka, M., Sasaki, C., Asada, C., Nakamura, Y.: Functionalization of the active Ingredients of Japanese green tea (Camellia sinensis) for the synthesis of bio-based epoxy resin. Ind. Crops Prod. 73, 63–72 (2015)

Abdul, K.H.P.S., Marliana, M.M., Alshammari, T.: Material properties of epoxy-reinforced biocomposites with lignin from empty fruit bunch as curing agent. BioResources 6, 5206–5223 (2011)

Yin, Q., Yang, W., Sun, C., Di, M.: Preparation and properties of lignin-epoxy resin composite. BioResources 7, 5737–5748 (2012)

Qin, J., Woloctt, M., Zhang, J.: Use of polycarboxylic acid derived from partially depolymerized lignin as a curing agent for epoxy application. ACS Sustain. Chem. Eng. 2, 188–193 (2013)

Kawamoto, H., Horigoshi, S., Saka, S.: Pyrolysis reactions of various lignin model dimers. J. Wood Chem. Technol. 27, 121–133 (2007)

Krevelen, D.W.V.: Some basic aspects of flame resistance of polymeric materials. Polymer 16, 615–620 (1975)

Asada, C., Sholahuddin, Nakamura, Y.: Chapter 9: Lignin as a Coating and Curing Agent on Biodegradable Epoxy Resins, Reactive and Functional Polymers Volume One. In: Gutiérrez, T.J. (eds.), Springer Nature Switzerland AG, pp.195–206 (2020)

Francis, B.: 22 Cure Kinetics of Epoxy/Thermoplastic Blends, Handbook of Epoxy Blends. In: Parameswaranpillai, J., Hameed, N., Pinonteck, J., Woo, E.M. (eds.) Springer Nature International Publishing AG, pp.649–674 (2017)

Deeraj, B.D.S., Harikrishnan, R., Jayan, J.S., Saritha, A., Joseph, K.: Enhanced visco-elastic and rheological behavior of epoxy composites reinforced with polyimide nanofiber. Nano-Struct. Nano-Objects 21, 100421 (2020)

Reddy, K.R., El-Zein, A., Airey, D.W., Alonso-Marroquin, F., Schubel, P., Manalo, A.: Self-healing polymers: synthesis methods and applications. Nano-Struct. Nano-Objects 23, 100500 (2020)

Basheer, B.V., George, J.J., Siengchin, S., Parameswaranpillai, J.: Polymer grafted carbon nanotubes-Synthesis, properties, and applications: a review. Nano-Struct. Nano-Objects 22, 100429 (2020)

Acknowledgements

The authors gratefully acknowledge the financial supports provided by a Grant-in-Aid for Young Scientists (A) (Grant No. 17H04717) and a Grant-in-Aid for Scientific Research (A) (Grant No. 20H00664) from the Ministry of Education, Culture, Sports, Science, and Technology of Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Asada, C., Honjo, K. & Nakamura, Y. Utilization of Steam-Treated and Milling-Treated Lignin from Moso Bamboo as Curing Agent of Epoxy Resin. Waste Biomass Valor 12, 6261–6272 (2021). https://doi.org/10.1007/s12649-021-01444-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01444-8