Abstract

In this work, cassava wastewater was used to evaluate hydrogen production and the subsequent production of caproic acid via acetate carbon chain elongation, adding ethanol as electron donor. Batch reactors were operated with an initial chemical oxygen demand of 10 and 20 g O2/L (A10 and A20, respectively), under self-fermentative operation at 40 ± 1 °C. The initial pH was set to 5.5 to inhibit methanogens growth. Hydrogen production yields were 1.01 and 1.98 mol H2/mol glucose for A10 and A20, respectively. In both cases, the main metabolites were ethanol and acetic, butyric, propionic, and caproic acids during the fermentative step; when adding ethanol for the chain elongation the pH was adjusted to 7.0 using a 2-M NaOH solution. The maximum total caproic acid concentration obtained after ethanol addition was 4.2 and 7.2 g/L for A10 and A20, respectively; of which 84% and 90% resulted from the carbon chain elongation step, respectively.

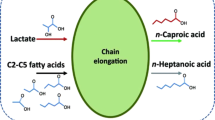

Graphic abstract

Similar content being viewed by others

References

Valdez-Vazquez, I., Poggi-Varaldo, H.M.: Hydrogen production by fermentative consortia. Renew. Sustain. Energy Rev. 13, 1000–1013 (2009). https://doi.org/10.1016/j.rser.2008.03.003

Wang, J., Wan, W.: Experimental design methods for fermentative hydrogen production: a review. Int. J. Hydrogen Energy 34, 235–244 (2009). https://doi.org/10.1016/j.ijhydene.2008.10.008

Van Ginkel, S., Sung, S., Lay, J.J.: Biohydrogen production as a function of pH and substrate concentration. Environ. Sci. Technol. 35, 4726–4730 (2001). https://doi.org/10.1021/es001979r

Wang, J., Wan, W.: Factors influencing fermentative hydrogen production: a review. Int. J. Hydrogen Energy 34, 799–811 (2009). https://doi.org/10.1016/j.ijhydene.2008.11.015

Ding, H.-B., Tan, G.-Y.A., Wang, J.-Y.: Caproate formation in mixed-culture fermentative hydrogen production. Bioresour. Technol. 101, 9550–9559 (2010). https://doi.org/10.1016/j.biortech.2010.07.056

Agler, M.T., Wrenn, B.A., Zinder, S.H., Angenent, L.T.: Waste to bioproduct conversion with undefined mixed cultures: the carboxylate platform. Special Issue-Appl. Microbiol. 29(2), 70–8 (2011). https://doi.org/10.1016/j.tibtech.2010.11.006

Kim, S.A., Rhee, M.S.: Marked synergistic bactericidal effects and mode of action of medium-chain fatty acids in combination with organic acids against Escherichia coli O157:H7. Appl. Environ. Microbiol. 79, 6552–6560 (2013). https://doi.org/10.1128/AEM.02164-13

Marshall, C.W., Labelle, E.V., May, H.D.: Production of fuels and chemicals from waste by microbiomes. Curr. Opin. Biotechnol. 24, 391–397 (2013). https://doi.org/10.1016/j.copbio.2013.03.016

Yesil, H., Taner, H., Nigiz, F.U., Hilmioglu, N., Tugtas, A.E.: Pervaporative separation of mixed volatile fatty acids: a study towards integrated VFA production and separation. Waste Biomass. Valor. 11, 1737–1753 (2018). https://doi.org/10.1007/s12649-018-0504-6

Steinbusch, K.J., Hamelers, H.V.M., Plugge, C.M., Buisman, C.J.N.: Biological formation of caproate and caprylate from acetate: fuel and chemicals from low grade biomass. Energy Environ. Sci. 4, 216–224 (2011). https://doi.org/10.1039/C0EE00282H

Huang, H.-J., Ramaswamy, S.: Overview of Biomass Conversion Processes and Separation and Purification Technologies in Biorefineries. Separation and Purification Technologies in Biorefineries, pp. 1–36. John Wiley & Sons Ltd, New Jersey (2013). https://doi.org/10.1002/9781118493441.ch1

Steinbusch, K.J.J., Hamelers, H.V.M., Buisman, C.J.N.: Alcohol production through volatile fatty acids reduction with hydrogen as electron donor by mixed cultures. Water Res. 42, 4059–4066 (2008). https://doi.org/10.1016/j.watres.2008.05.032

Karumanchi, R.S.M.S., Doddamane, S.N., Sampangi, C., Todd, P.W.: Field-assisted extraction of cells, particles and macromolecules. Trends Biotechnol. 20, 72–78 (2002). https://doi.org/10.1016/S0167-7799(01)01847-9

Zacharof, M.-P., Lovitt, R.W.: Complex effluent streams as a potential source of volatile fatty acids. Waste Biomass. Valor. 4, 557–581 (2013). https://doi.org/10.1007/s12649-013-9202-6

Spirito, C.M., Richter, H., Rabaey, K., Stams, A.J.M., Angenent, L.T.: Chain elongation in anaerobic reactor microbiomes to recover resources from waste. Curr. Opin. Biotechnol. 27, 115–122 (2014). https://doi.org/10.1016/j.copbio.2014.01.003

Cappelletti, B.M., Reginatto, V., Amante, E.R., Antônio, R.V.: Fermentative production of hydrogen from cassava processing wastewater by clostridium acetobutylicum. Renew. Energy 36(12), 3367–3372 (2011). https://doi.org/10.1016/j.renene.2011.05.015

Intanoo, P., Chaimongkol, P., Chavadej, S.: Hydrogen and methane production from cassava wastewater using two-stage upflow anaerobic sludge blanket reactors (UASB) with an emphasis on maximum hydrogen production. Int. J. Hydrogen Energy 41, 6107–6114 (2016). https://doi.org/10.1016/j.ijhydene.2015.10.125

Rosa, P.R.F., Gomes, B.C., Varesche, M.B.A., Silva, E.L.: Characterization and antimicrobial activity of lactic acid bacteria from fermentative bioreactors during hydrogen production using cassava processing wastewater. Chem. Eng. J. 284, 1–9 (2016). https://doi.org/10.1016/j.cej.2015.08.088

Lui, M.Y., Wong, C.Y.Y., Choi, A.W.-T., Mui, Y.F., Qi, L., Horváth, I.T.: valorization of carbohydrates of agricultural residues and food wastes: a key strategy for carbon conservation. ACS Sustain. Chem. Eng. 7(21), 17799–17807 (2019). https://doi.org/10.1021/acssuschemeng.9b04242

Grootscholten, T.I.M., Steinbusch, K.J.J., Hamelers, H.V.M., Buisman, C.J.N.: Chain elongation of acetate and ethanol in an upflow anaerobic filter for high rate MCFA production. Bioresour. Technol. 135, 440–445 (2013). https://doi.org/10.1016/j.biortech.2012.10.165

Fernandes, B.S., Peixoto, G., Albrecht, F.R., Saavedra del Aguila, N.K., Zaiat, M.: Potential to produce biohydrogen from various wastewaters. Energy Sustain. Dev. 14(2), 143–148 (2010). https://doi.org/10.1016/j.esd.2010.03.004

APHA: Standard methods for the examination for water and wastewater, 20th edn. American Public Health Association/American Water Works Association/Water Environmental Federation, Washington, DC (2012)

Dubois, S.M., Gilles, K.A., Hamilton, J.L., Rebers, P.A., Smith, F.: Colorimetric methods for determination of sugar and related substance. Anal. Chem. 28(3), 350–356 (1956). https://doi.org/10.1021/ac60111a017

Moraes EM, Adorno MAT, Zaiat M, Foresti E (2000) Determinação de ácidos voláteis por cromatografia gasosa em efluentes de reatores anaeróbios tratando resíduos líquidos e sólidos. In: VI Oficina e Seminário Latino-Amerocano de Digestão Anaeróbia. Anais da VI Oficina e Seminário Latino-Amerocano de Digestão Anaeróbia, v 2. Recife – PE: Universitária – UFPE 235–238 [in Portuguese].

Chen, W.-H., Chen, S.-Y., Khanal, S.K., Sung, S.: Kinetic study of biological hydrogen production by anaerobic fermentation. Int. J. Hydrogen Energy 31, 2170–2178 (2006). https://doi.org/10.1016/j.ijhydene.2006.02.020

Amorim, E.L.C., Sader, L.T., Silva, E.L.: Effect of Substrate Concentration on Dark Fermentation Hydrogen Production Using an Anaerobic Fluidized Bed. Appl. Biochem. Biotechnol. 166, 1248–1263 (2012). https://doi.org/10.1007/s12010-011-9511-9

Penteado, E.D., Lazaro, C.Z., Sakamoto, I.K., Zaiat, M.: Influence of seed sludge and pretreatment method on hydrogen production in packed-bed anaerobic reactors. Int. J Hydrogen Energy 38, 6137–6145 (2013). https://doi.org/10.1016/j.ijhydene.2013.01.067

Harper, S.R., Pohland, F.G.: Recent development in hydrogen management during wastewater treatment. Biotechnol. Bioeng 28, 585–602 (1986). https://doi.org/10.1002/bit.260280416

Wang, W., Xie, L., Luo, G., Zhou, Q.: Enhanced fermentative hydrogen production from cassava stillage by co-digestion: the effects of different co-substrates. Int. J. Hydrogen Energy 38, 6980–6988 (2013). https://doi.org/10.1016/j.ijhydene.2013.04.004

Luo, G., Xie, L., Zou, Z., Wang, W., Zhou, Q.: Exploring optimal conditions for thermophilic fermentative hydrogen production from cassava stillage. Int. J. Hydrogen Energy 35, 6161–6169 (2010). https://doi.org/10.1016/j.ijhydene.2010.03.126

Onyenwoke, R.U., Wiegel, J.: Thermoanaerobacter. Bergey’s Manual of Systematic Bacteriology, vol. 3, pp. 1225–39. Springer, New York, Heidelberg (2009). https://doi.org/10.1002/9781118960608.gbm00755

Grootscholten, T.I.M., Strik, D.P.B.T.B., Steinbusch, K.J.J., Buisman, C.J.N., Hamelers, H.V.M.: Two-stage medium chain fatty acid (MCFA) production from municipal solid waste and ethanol. Appl. Energy 116, 223–229 (2014). https://doi.org/10.1016/j.apenergy.2013.11.061

Ge, S., Usack, J., Spirito, C.M., Angenent, L.T.: Long-term n-caproic acid production from yeast-fermentation beer in an anaerobic bioreactor with continuous product extraction. Environ. Sci. Technol. 49(13), 8012–8021 (2015). https://doi.org/10.1021/acs.est.5b00238

Acknowledgements

The authors gratefully acknowledge the financial support of the Brazilian agencies, National Council for the Scientific and Technological Development (CNPq—processes 441495/2014–1 and 408420/2016–2), Foundation for the Development of Science and Technology of Pernambuco (FACEPE—process APQ 0603–3.07/14), and Coordination of Superior Level Staff Improvement (CAPES Proap); and the flour factory of Mr. Breu for the samples of cassava wastewater.

Funding

This work was supported by the National Council for the Scientific and Technological Development (CNPq—processes 441495/2014–1 and 408420/2016–2); Foundation for the Development of Science and Technology of Pernambuco (FACEPE – process APQ 0603–3.07/14); and Coordination of Superior Level Staff Improvement (CAPES Proap).

Author information

Authors and Affiliations

Contributions

NA: Methodology, Formal analysis, Investigation, Writing—Original Draft, Visualization. EA: Funding acquisition. MK: Writing—Review & Editing. LF: Conceptualization, Funding acquisition. SG: Conceptualization, Methodology, Writing—Review & Editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gavazza, S., Amorim, N.C.S., Kato, M.T. et al. Caproic Acid Formation by Carbon Chain Elongation During Fermentative Hydrogen Production of Cassava Wastewater. Waste Biomass Valor 12, 2365–2373 (2021). https://doi.org/10.1007/s12649-020-01174-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01174-3