Abstract

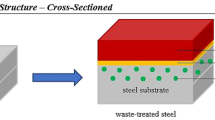

The aim of this research is to find possible ways to recycle and re-use industrial solar cell scrap. The work is concentrated on cells which are broken, damaged or rejected during the manufacturing process, which accounts from 2 to 3 percent of whole production on average. Different chemical methods have been suggested for the recovery of pure valuable elements from damaged or worn cells, while the technology presented in this paper utilizes industrial solar cell scrap to produce secondary value products. Crushed industrial waste of different fraction sizes was analyzed using scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and X-ray diffraction (XRD) methods. Tungsten inert gas welding (TIG) has been chosen as the coating formation process. Proper parameters: current 55 A, voltage 19 V, gas flow rate 5 l/min, torch tilt angle 80–85° were selected experimentally, as parameters of common welding are not suitable for the deposition. The chemical composition and transition of chemical elements towards the substrate showed sufficient adhesion and smooth distribution of elements. Alongside with aforementioned methods, mechanical tests were accomplished, showing that damaged solar cells industrial scrap could be used as a source of alloying elements to compose the coating. The hardness of produced coatings as deposited reached 39 HRC (microhardness 2 GPa) on average. Formed coatings could serve for various applications, however further in-depth research is necessary. As suggested, the wear test method is too aggressive for this type of surface. Nevertheless, coatings based on industrial solar cell scrap showed a mass loss two times lower on average than normalized structural steel S355 substrate in rough abrasive conditions.

Graphic Abstract

Similar content being viewed by others

References

Skripkiūnas, G., Vasarevičius, S., Danila, V.: Immobilization of copper indium selenide solar module waste in concrete constructions. Cement Concr. Comp. (2018). https://doi.org/10.1016/j.cemconcomp.2017.10.009

Müller, A., Wambach, K., Alsema, E.: Life Cycle Analysis of Solar Module Recycling Process. MRS Proceedings 895, 3211–3213 (2005). https://doi.org/10.1557/PROC-0895-G03-07

Fernández, L.J., Ferrer, R., Aponte, D.F., Fernández, P.: Recycling silicon solar cell waste in cement-based systems. Sol. Energ. Mat. Sol. C (2011). https://doi.org/10.1016/j.solmat.2011.01.033

Hansen, J.P., Narbel, P.A., Aksnes, D.L.: Limits to growth in the renewable energy sector. Renew. Sustain. Energy Rev. 70, 769–774 (2017). https://doi.org/10.1016/j.rser.2016.11.257

Yousef, S., Tatariants, M., Denafas, J., Makarevicius, V., Lukošiūtė, S., Kruopienė, J.: Sustainable industrial technology for recovery of Al nanocrystals, Si micro-particles and Ag from solar cell wafer production waste. Sol. Energy Mat. Sol. C (2019). https://doi.org/10.1016/j.solmat.2018.12.008

Şengül, H., Theis, T.L.: An environmental impact assessment of quantum dot photovoltaics (QDPV) from raw material acquisition through use. J. Clean. Prod. (2011). https://doi.org/10.1016/j.jclepro.2010.08.010

Contreras-Lisperguer R., Muñoz-Cerón E., Aguilera J., Casa J.d.l.: Cradle-to-cradle approach in the life cycle of silicon solar photovoltaic panels. J Clean Prod, (2017).

Fthenakis, V.M.: End-of-life management and recycling of PV modules. Energ Policy (2000). https://doi.org/10.1016/S0301-4215(00)00091-4

Xu, Y., Li, J., Tan, Q., Peters, A.L., Yang, C.: Global status of recycling waste solar panels: a review. Waste Manage (2018). https://doi.org/10.1016/j.wasman.2018.01.036

Aman, M.M., Solangi, K.H., Hossain, M.S., Badarudin, A., Jasmon, G.B., Mokhlis, H., Bakar, A.H.A., Kazi, S.N.: A review of Safety, Health and Environmental (SHE) issues of solar energy system. Renew. Sust. Energ. Rev. (2015). https://doi.org/10.1016/j.rser.2014.08.086

Mahmoudi, S., Huda, N., Behnia, M.: Environmental impacts and economic feasibility of end of life photovoltaic panels in Australia: a comprehensive assessment. J. Clean. Prod. 260, 120996 (2020). https://doi.org/10.1016/j.jclepro.2020.120996

Chowdhury, M.S., Rahman, K.S., Chowdhury, T., Nuthammachot, N., Techato, K., Akhtaruzzaman, M., Tiong, S.K., Sopian, K., Amin, N.: An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 27, 100431 (2020). https://doi.org/10.1016/j.esr.2019.100431

D’Adamo, I., Miliacca, M., Rosa, P.: Economic feasibility for recycling of waste crystalline siliconphotovoltaic modules. Int. J. Photoenergy 2017, 1–6 (2017). https://doi.org/10.1155/2017/418467

Del Pero, F., Delogu, M., Berzi, L., Escamilla, M.: Innovative device for mechanical treatment of end of Life photovoltaic panels: technical and environmental analysis. Waste Manage. 95, 535–548 (2019). https://doi.org/10.1016/j.wasman.2019.06.037

Cyrs, W.D., Avens, H.J., Capshaw, Z.A., Kingsbury, R.A., Sahmel, J., Tvermoes, B.E.: Landfill waste and recycling: use of a screening-level risk assessment tool for end-of-life cadmium telluride (CdTe) thin-film photovoltaic (PV) panels. Energ Policy (2014). https://doi.org/10.1016/j.enpol.2014.01.025

Savvilotidou, V., Antoniou, A., Gidarakos, E.: Toxicity assessment and feasible recycling process for amorphous silicon and CIS waste photovoltaic panels. Waste Manage (2017). https://doi.org/10.1016/j.wasman.2016.10.003

Moen, M., Halvorsen, T., Mørk, K., Velken, S.: Recycling of silicon metal powder from industrial powder waste streams. Met. Powder Rep. (2017). https://doi.org/10.1016/j.mprp.2016.04.005

Lin, Y., Wang, T., Lan, C., Tai, C.Y.: Recovery of silicon powder from kerf loss slurry by centrifugation. Powder Technol. (2010). https://doi.org/10.1016/j.powtec.2010.02.028

Woditsch, P., Koch, W.: Solar grade silicon feedstock supply for PV industry. Sol. Energ. Mat. Sol. C (2002). https://doi.org/10.1016/S0927-0248(01)00146-5

Xing P.F., Zhao P.Y., Guo J., Liu Y., Li F., Tu G.F.: Recovery of cutting slurry waste of solar-grade silicon. Mater. Rev., 75–80 (2011)

Wang T.Y., Lin Y.C., Tai C.Y., Fei C.C., Tseng M.Y., Lan C.W.: Recovery of silicon from kerf loss slurry waste for photovoltaic applications. Prog. Photovol. Res. Appl., 155–163 (2010)

Jang H.D., Kim H., Chang H., Kim J., Roh K.M., Choi J.H., Cho B.G., Park E., Kim H., Luo J., Huang J.X.: Aerosol-Assisted Extraction of Silicon Nanoparticles from Wafer Slicing Waste for Lithium Ion Batteries. Sci. Rep., 9431 (2015)

Liu, Y., Kong, J., Zhuang, Y., Xing, P., Yin, H., Luo, X.: Recycling high purity silicon from solar grade silicon cutting slurry waste by carbothermic reduction in the electric arc furnace. J. Clean. Prod. (2019). https://doi.org/10.1016/j.jclepro.2019.03.187

Fthenakis, V.: Sustainability of photovoltaics: The case for thin-film solar cells. Renew. Sust. Energ. Rev. (2009). https://doi.org/10.1016/j.rser.2009.05.001

Gustafsson, A.M.K., Foreman, M.R.S., Ekberg, C.: Recycling of high purity selenium from CIGS solar cell waste materials. Waste Manage (2014). https://doi.org/10.1016/j.wasman.2013.12.021

Yousef, S., Tatariants, M., Tichonovas, M., Makarevicius, V.: Sustainable technology for mass production of Ag nanoparticles and Al microparticles from damaged solar cell wafers. Waste Manage (2019). https://doi.org/10.1016/j.wasman.2019.08.019

Jimenez-Millan, J., Abad, I., Jimenez-Espinosa, R., Yebra-Rodriguez, A.: Assessment of solar panel waste glass in the manufacture of sepiolite based clay bricks. Mater. Lett. (2018). https://doi.org/10.1016/j.matlet.2018.02.049

Bendikiene, R., Ciuplys, A., Kavaliauskiene, L.: Circular economy practice: from industrial metal waste to production of high wear resistant coatings. J. Clean. Prod. (2019). https://doi.org/10.1016/j.jclepro.2019.05.068

Bendikiene, R., Ciuplys, A., Pupelis, E.: Research on possibilities to replace industrial wear plates by surfaced coatings using waste materials. Int J Surf Sci Eng 10, 330–338 (2016). https://doi.org/10.1504/IJSURFSE.2016.077535

Sharma, D., Ghosh, P.K., Kumar, S., Das, S., Anant, R., Kumar, N.: Surface hardening by in-situ grown composite layer on microalloyed steel employing TIG arcing process. Surf. Coat. Tech. (2018). https://doi.org/10.1016/j.surfcoat.2018.08.009

Ghosh, P.K., Kumar, R.: Surface modification of micro-alloyed high-strength low-alloy steel by controlled TIG arcing process. Metall. Mater. Trans. A 46, 831–842 (2015). https://doi.org/10.1007/s11661-014-2670-x

Heigel, J.C., Gouge, M.F., Michaleris, P., Palmer, T.A.: Selection of powder or wire feedstock material for the laser cladding of Inconel® 625. J. Mater. Process. Tech. (2016). https://doi.org/10.1016/j.jmatprotec.2016.01.004

Bruker AXS:TOPAS V4: General profile and structure analysis software for powder diffraction data. User's Manual, Bruker AXS (2008)

Cheary, R.W., Coelho, A.A., Cline, J.P.: Fundamental parameters line profile fitting in laboratory diffractometers. J. Res. Natl. Inst. Stand. Technol. 109, 1–25 (2004)

Rietveld, H.M.: Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallog.r 22, 151–152 (1967)

Sabzi, M., Dezfuli, S.M., Far, S.M.: Deposition of Ni-tungsten carbide nanocomposite coating by TIG welding: characterization and control of microstructure and wear/corrosion responses. Ceram. Int. 42, 22816–22829 (2018). https://doi.org/10.1016/j.ceramint.2018.09.073

Junting, X., Fiona, F.C., Hunkwan, P., Tanaka, K., Shigeta, M., Tanaka, M., Murphy, A.B.: Numerical study of the metal vapour transport in tungsten inert-gas welding in argon for stainless steel. Appl. Math. Model. 79, 713–728 (2020). https://doi.org/10.1016/j.apm.2019.11.001

Gražulis, S., Chateigner, D., Downs, R.T., Yokochi, A.F.T., Quirós, M., Lutterotti, L., Manakova, E., Butkus, J., Moeck, P., Le Bail, A.: crystallography open database - an open-access collection of crystal structures. J. Appl. Cryst. 42, 726–729 (2009). https://doi.org/10.1107/S0021889809016690

Renewable power generation costs in 2019. International Renewable Energy Agency, ISBN 978-92-9260-244-4.

Funding

This work was supported by the Research, Development and Innovation Fund of Kaunas University of Technology [Grant Number PP-88H/19] and the Research, Development and Innovation Transfer Department of Lithuanian Energy Institute (SELDAN).

Author information

Authors and Affiliations

Contributions

RB—Writing—Original Draft, Project administration, Supervision; AB—Formal analysis, Methodology, Conceptualization; AC—Investigation, Data Curation, Writing—Review and Editing; IL—Investigation, Visualization, Data Curation; KJ—Investigation, Visualization, Data Curation; RLD—Investigation, Visualization, Data Curation; RS—Investigation, Formal analysis; JD—Investigation, Formal analysis.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bendikiene, R., Baltusnikas, A., Ciuplys, A. et al. Utilization of Industrial Solar Cells’ Scrap as the Base Material to Form Coatings. Waste Biomass Valor 12, 2757–2767 (2021). https://doi.org/10.1007/s12649-020-01153-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01153-8